Customization & Tailored Manufacturing Solution

At Haitian Heavy Industry, we understand that standard wear parts often fall short in meeting the specific requirements of heavy-duty industries. That’s why we offer end-to-end custom manufacturing solutions for cast components and wear-resistant parts—designed to meet your operational environment, technical specifications, and cost goals.

Whether you’re in mining, asphalt mixing, cement production, steelworks, or construction, we support you from drawing to delivery. Our expertise ensures your parts are precisely engineered for durability, performance, and lifecycle optimization.

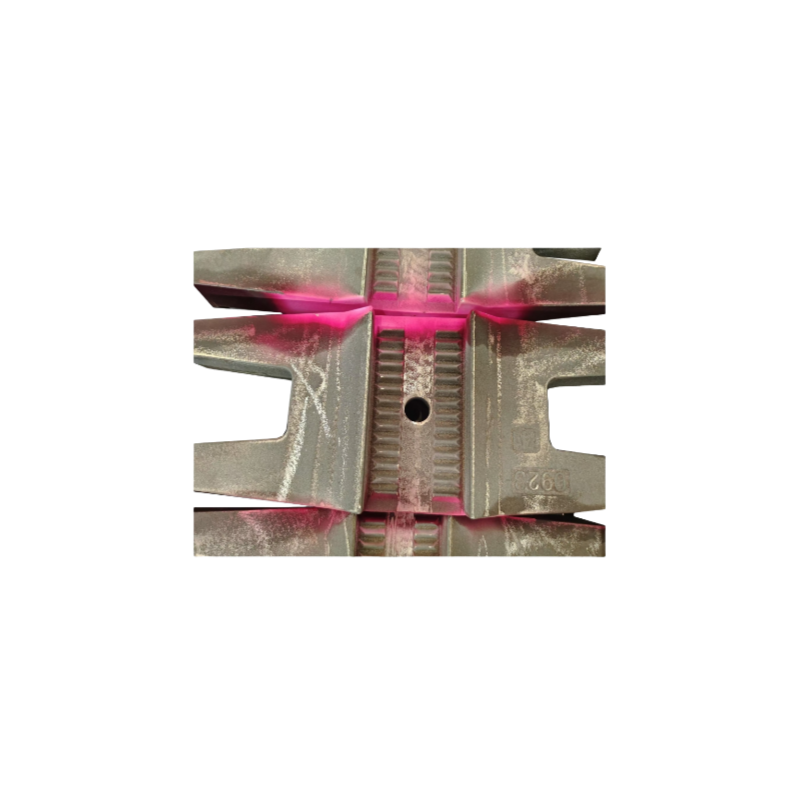

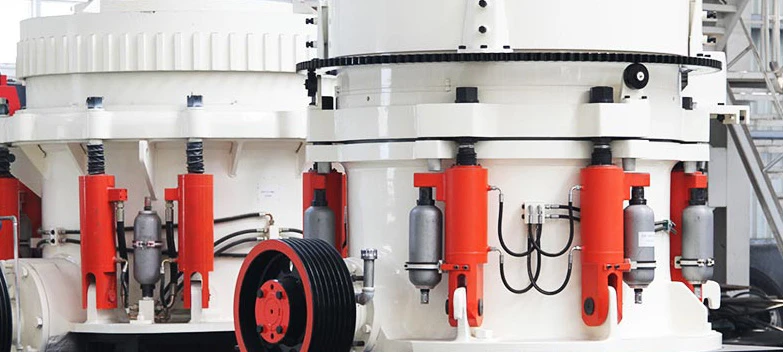

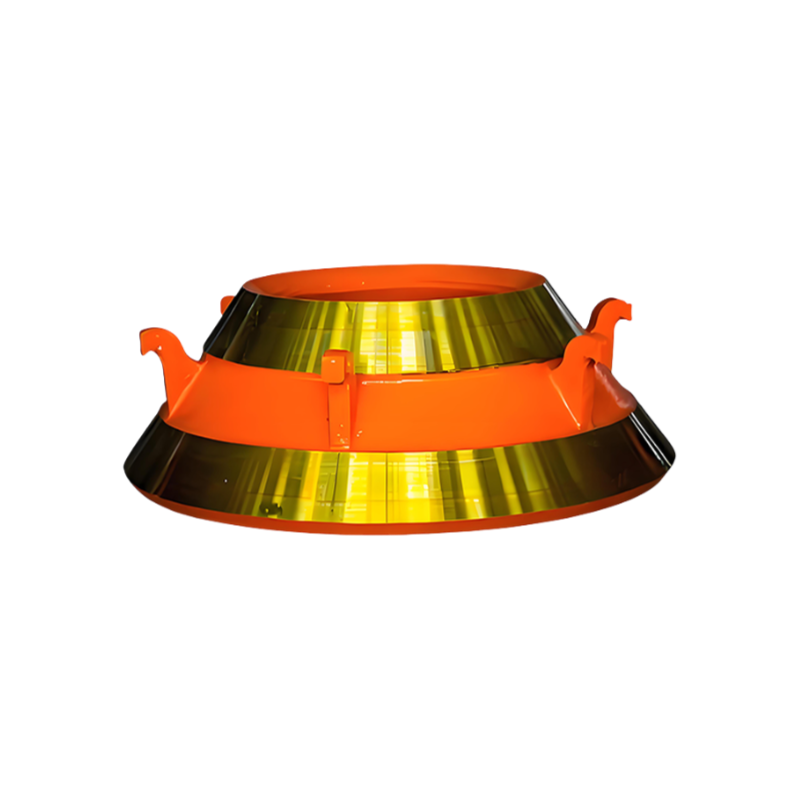

Customized Wear Parts

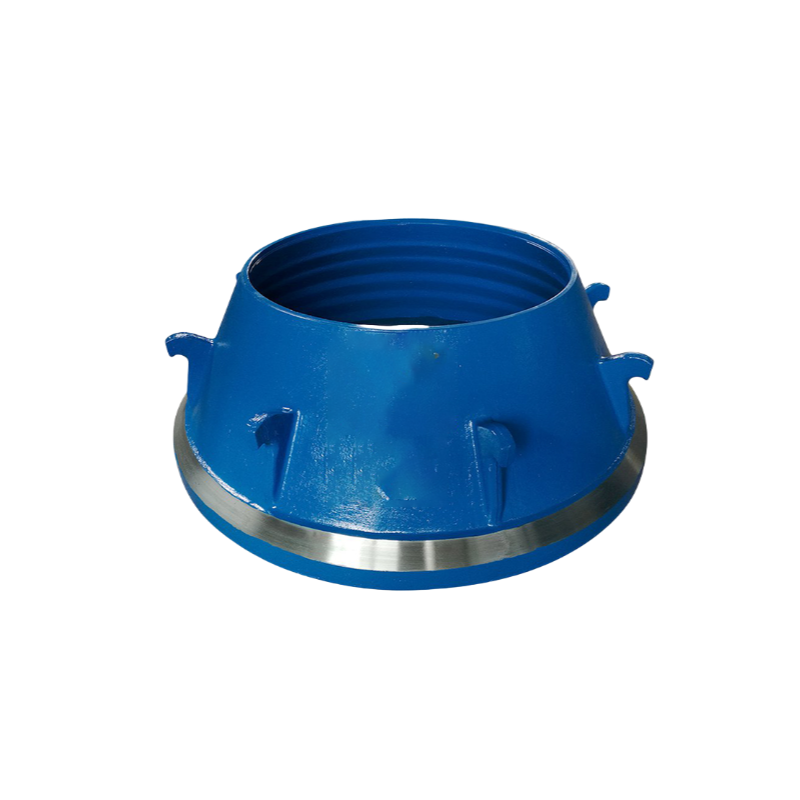

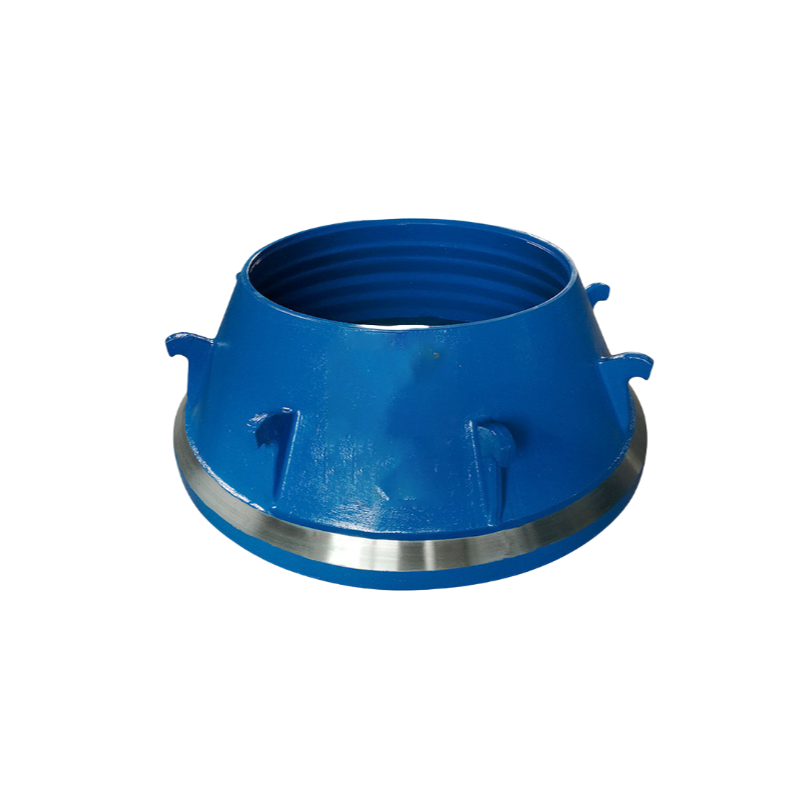

- Cone Crusher Parts

- Concrete Mixing Plant Parts

- Smelting Equipment Parts

- Asphalt Mixing Plant Parts

-

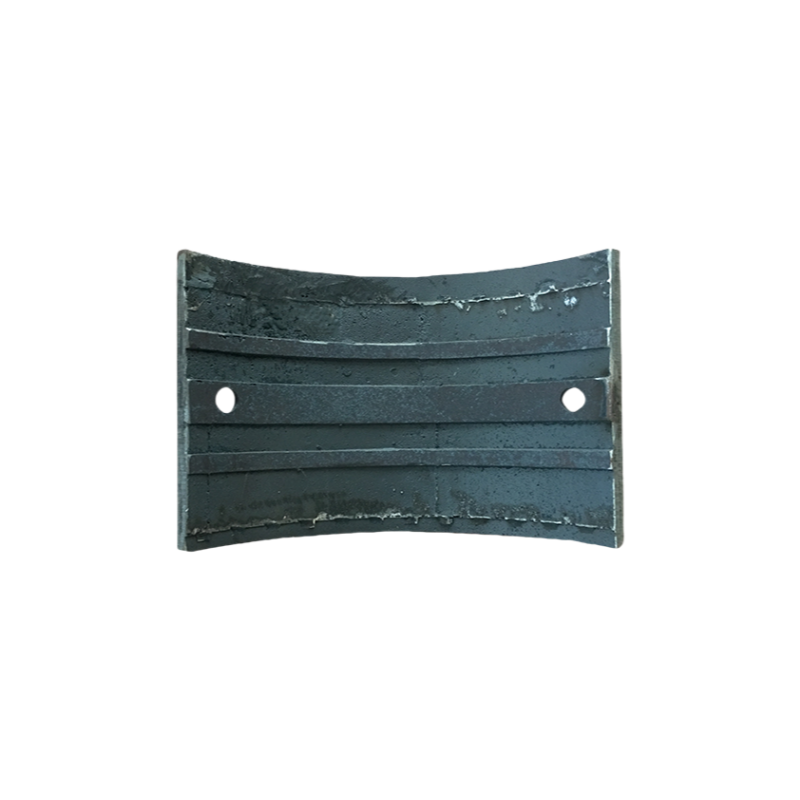

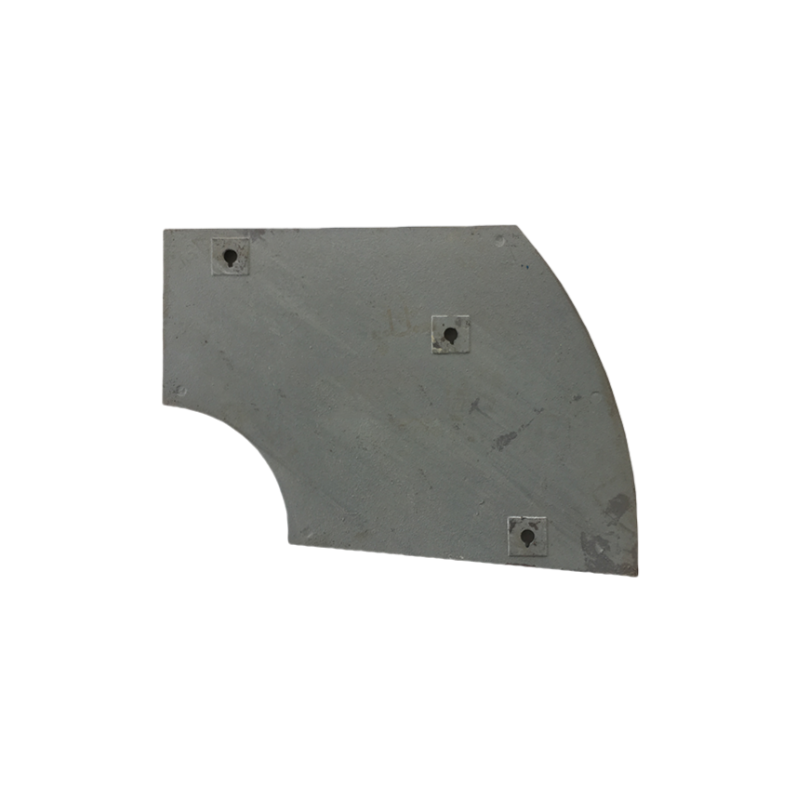

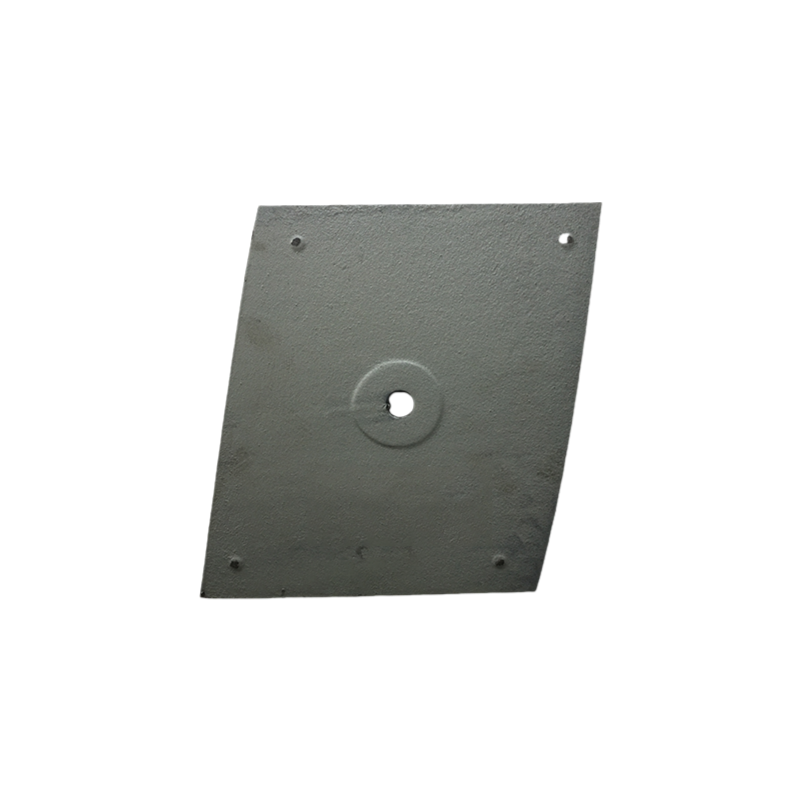

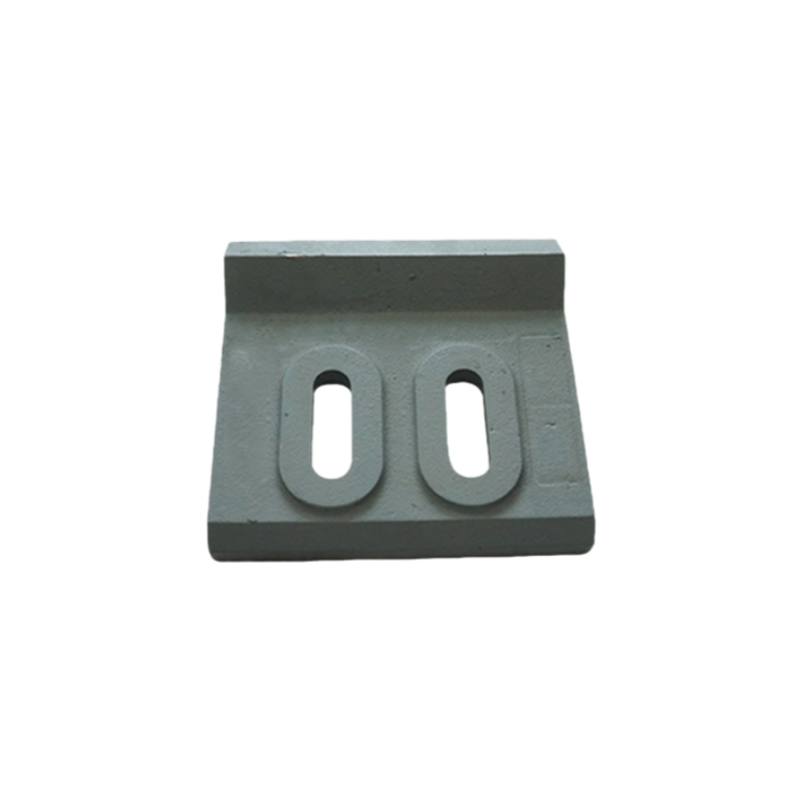

Wear-resistant Lining Plate

-

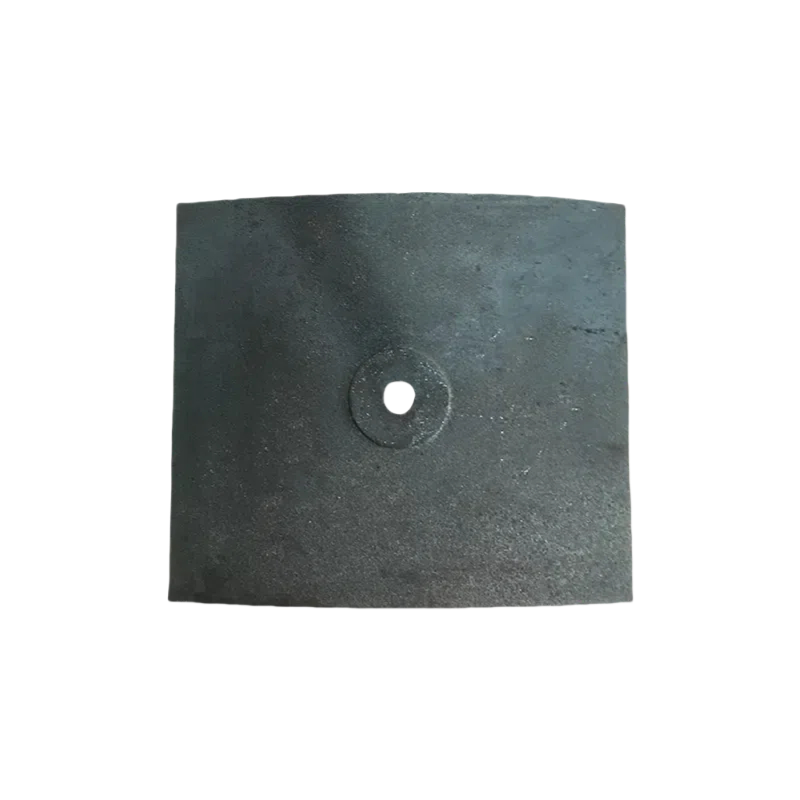

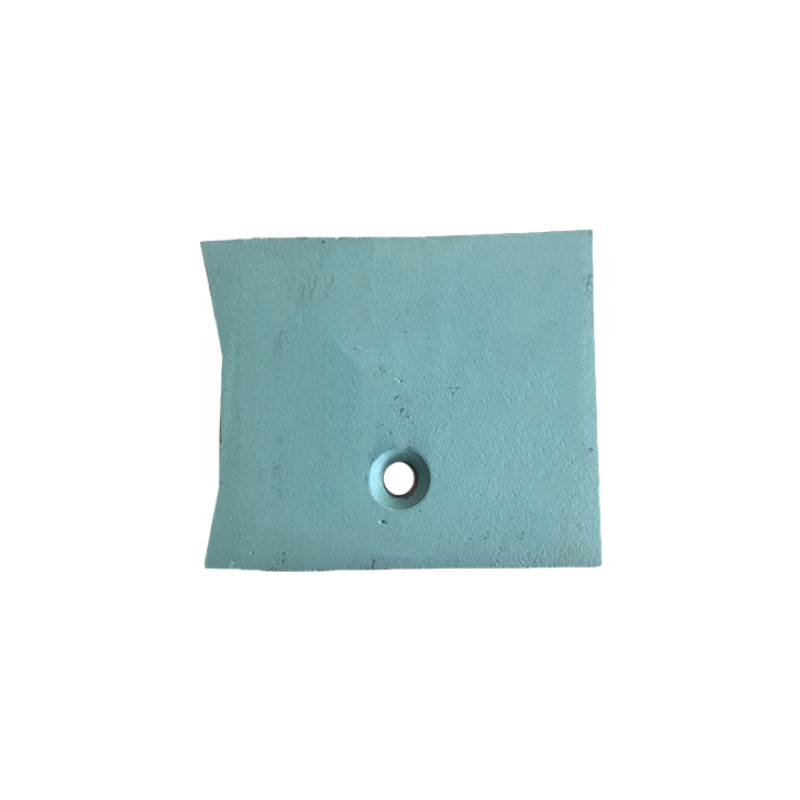

Impact Resistant Lining plate For Concrete Mixing Plant

-

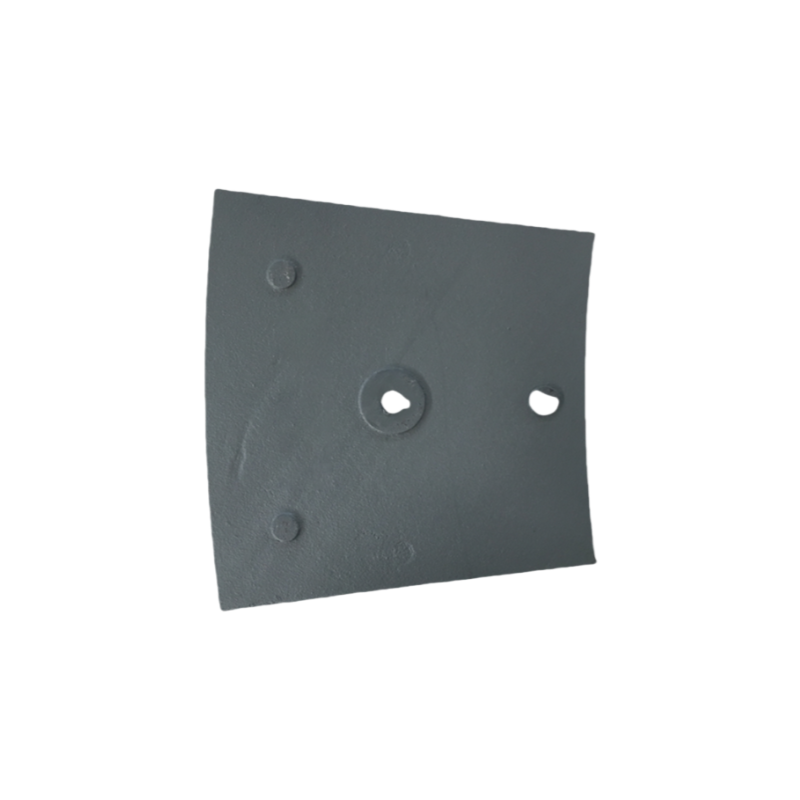

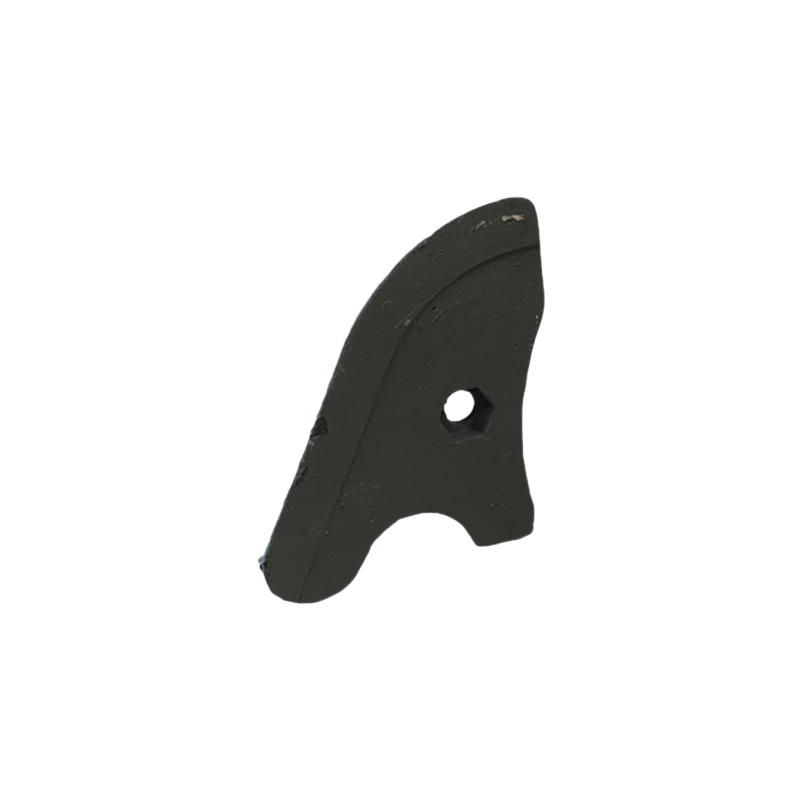

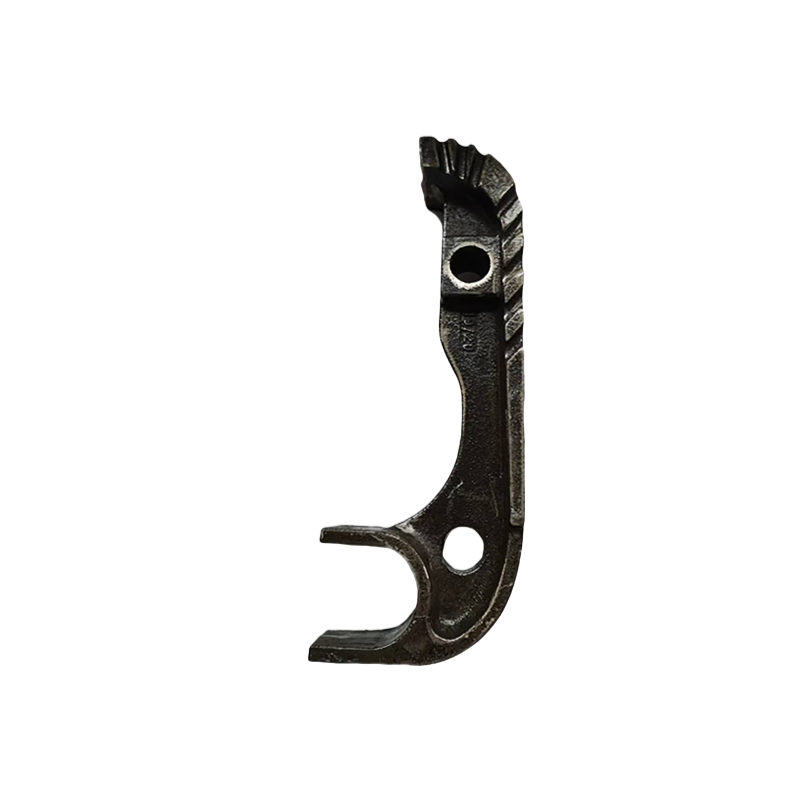

Mixing Arm For Concrete Mixing Plant

-

Concrete Mixing Plant Heat-resisting Lining Plate

-

Customizable Mixing Arm For Concrete Mixing Plant

-

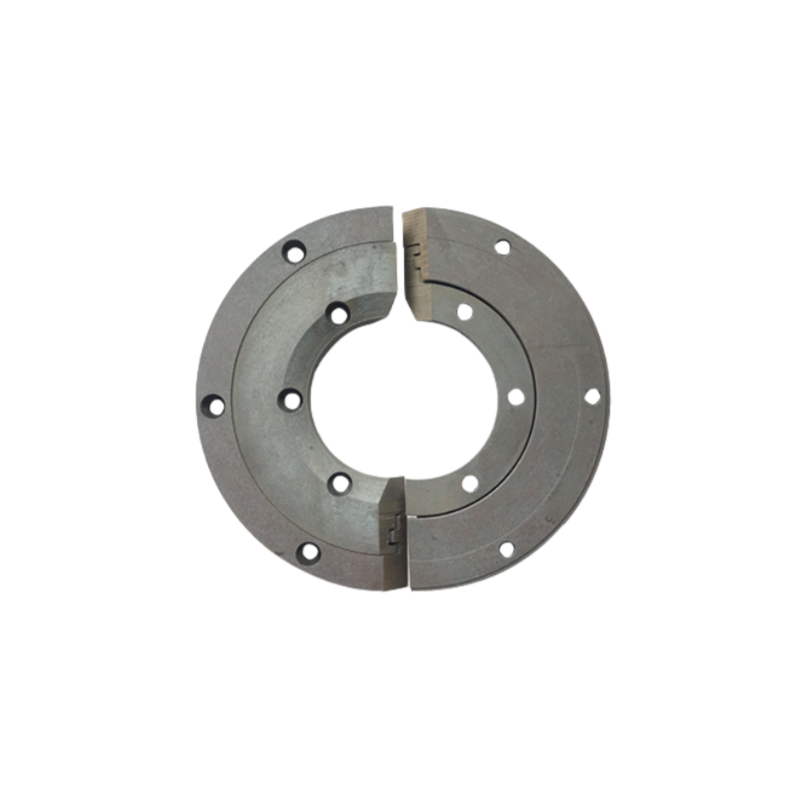

Concrete Mixing Plant Wear Resistant Seal

-

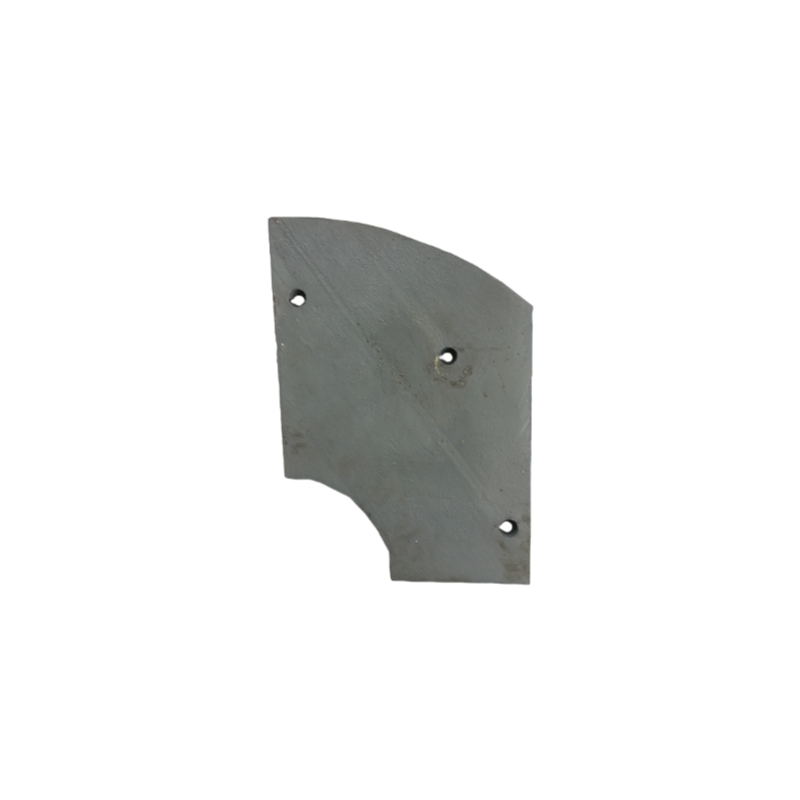

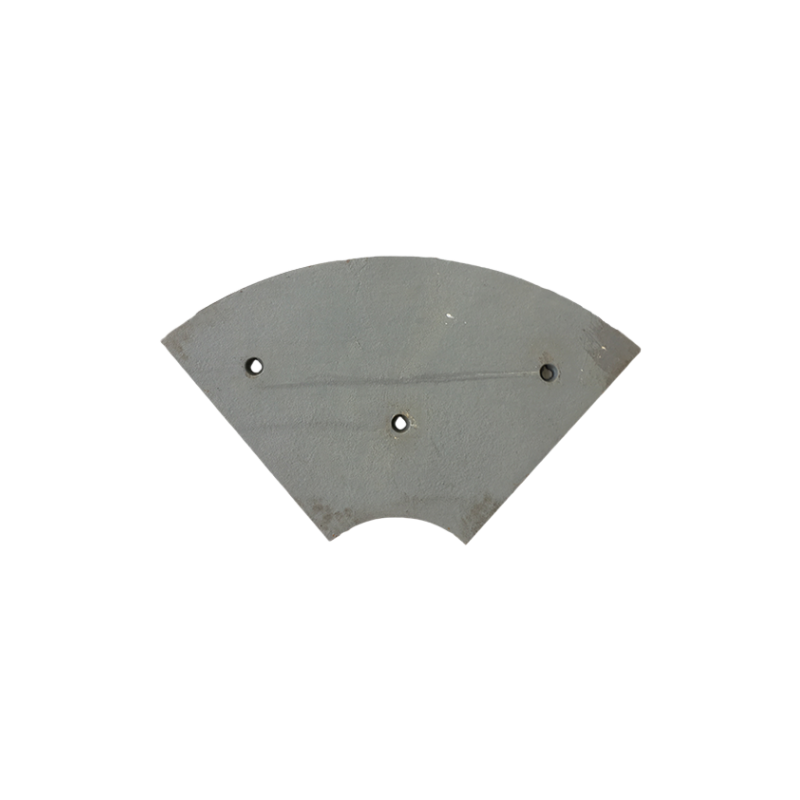

Discharge Door ARC Liner

-

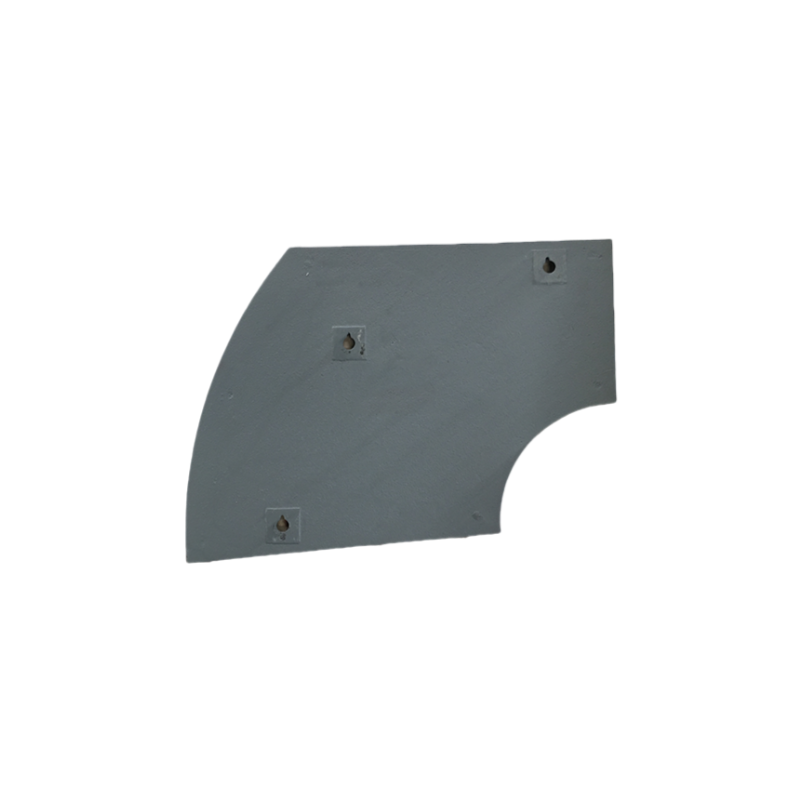

Lining Plate-Concrete Machinery

-

High Temperature Tolerance Lining Plate

-

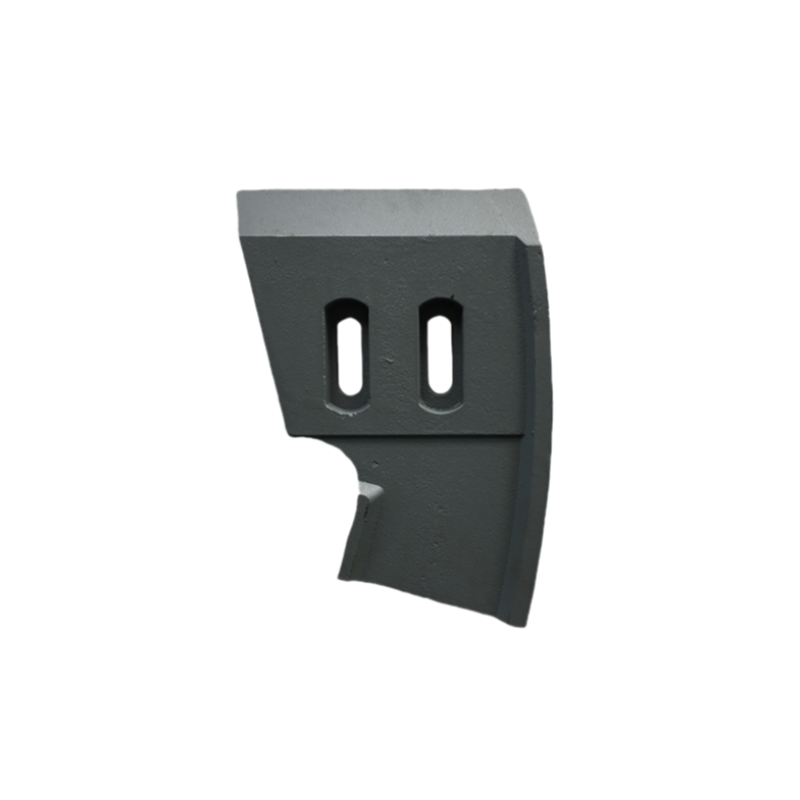

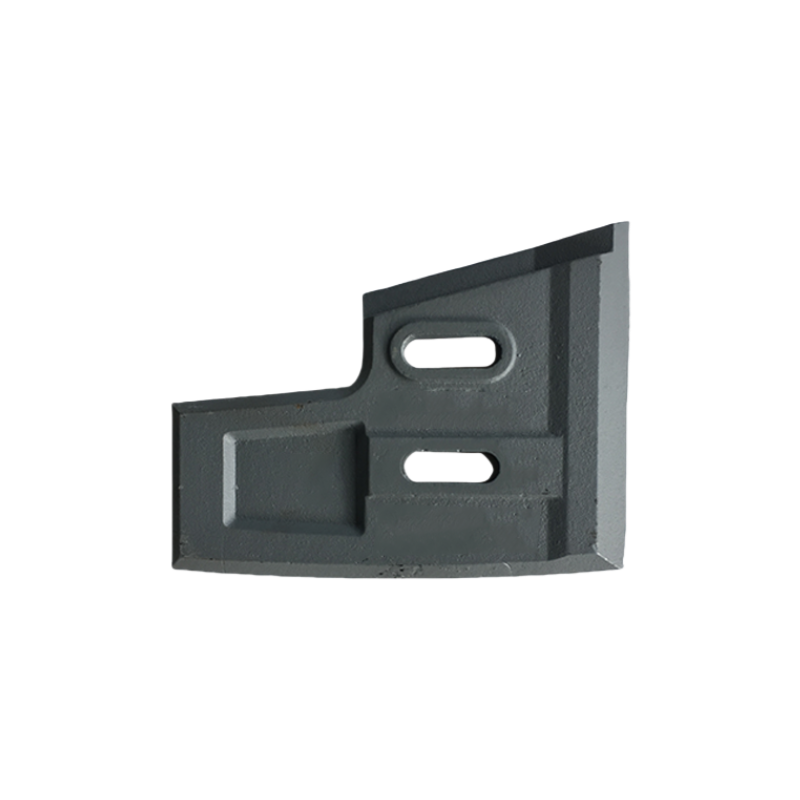

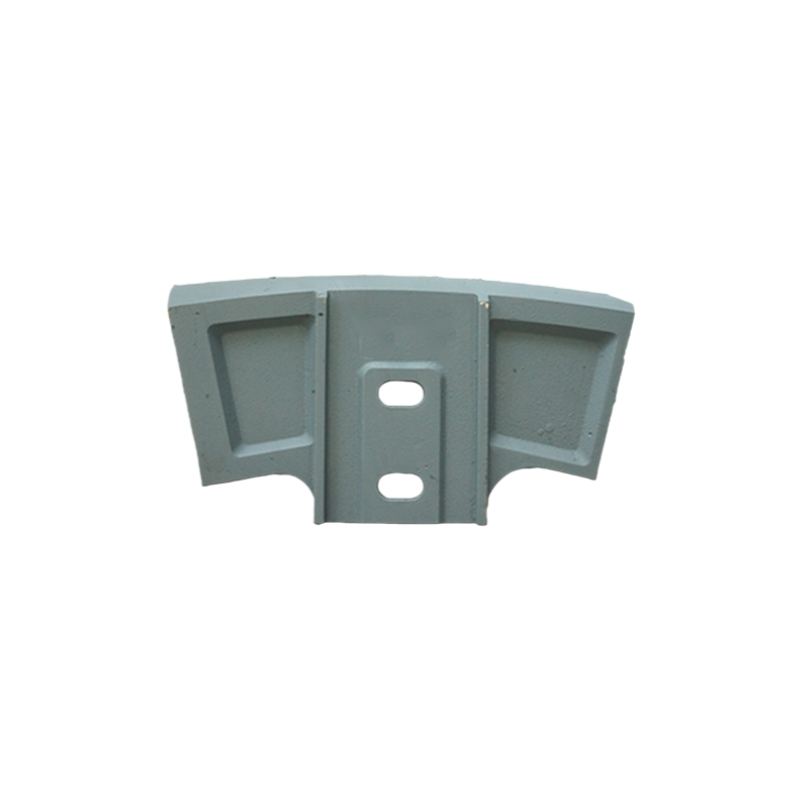

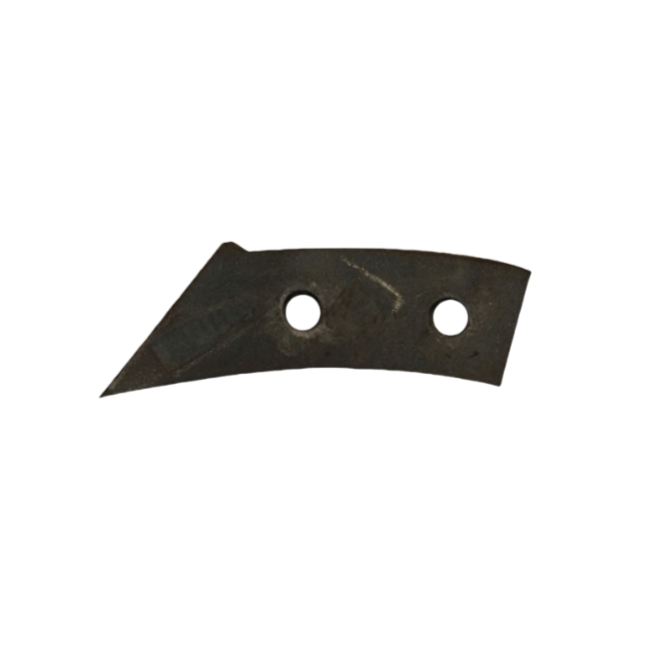

Economical & Corrosion Resistance Blade

-

Diverse Choices Lining Plate

-

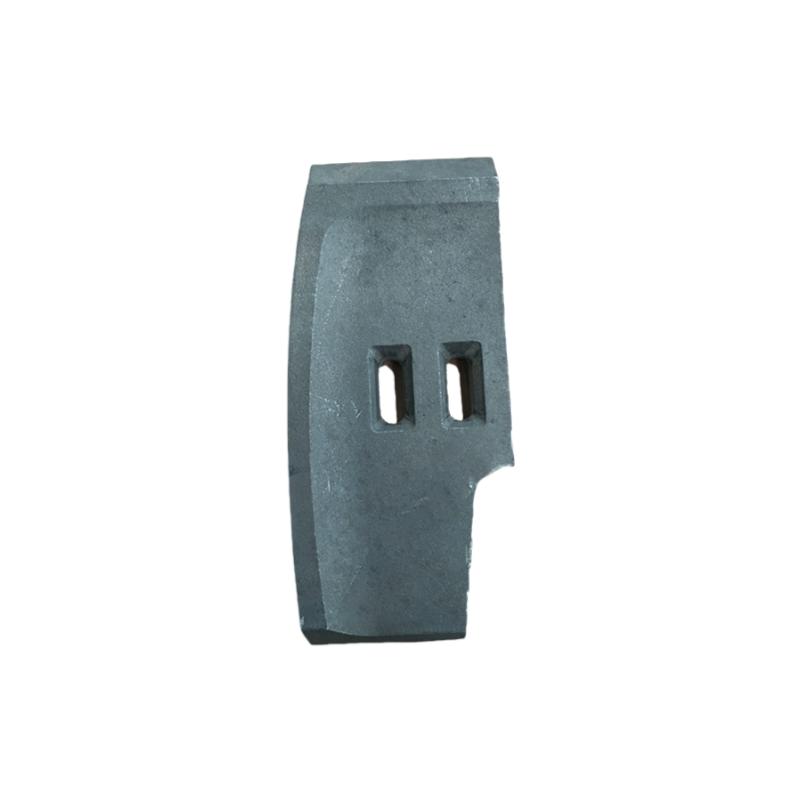

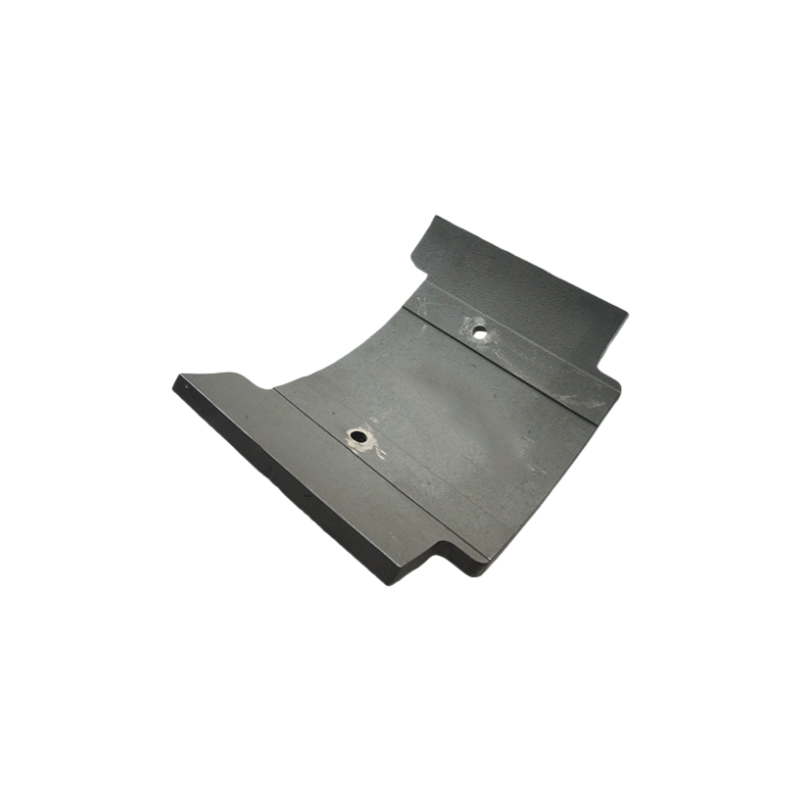

Concrete Scraper High Efficiency

-

High Strength Lining Plate

-

Corrosion Resistance Scraper

-

Full Series Lining Plate

-

General Lining Plate For Concrete Mixing Plant

-

OEM Lining Plate For Concrete Mixing Plant

-

Concrete Mixing Plant Iron Casting Scraper

-

Concrete Mixing Plant Wear-resistant Lining Plate

-

High Hardness Lining Plate For Concrete Mixing Plant

-

Arm Protection-Concrete Mixing Plant

-

Mixing Arm-Concrete Mixing Plant

-

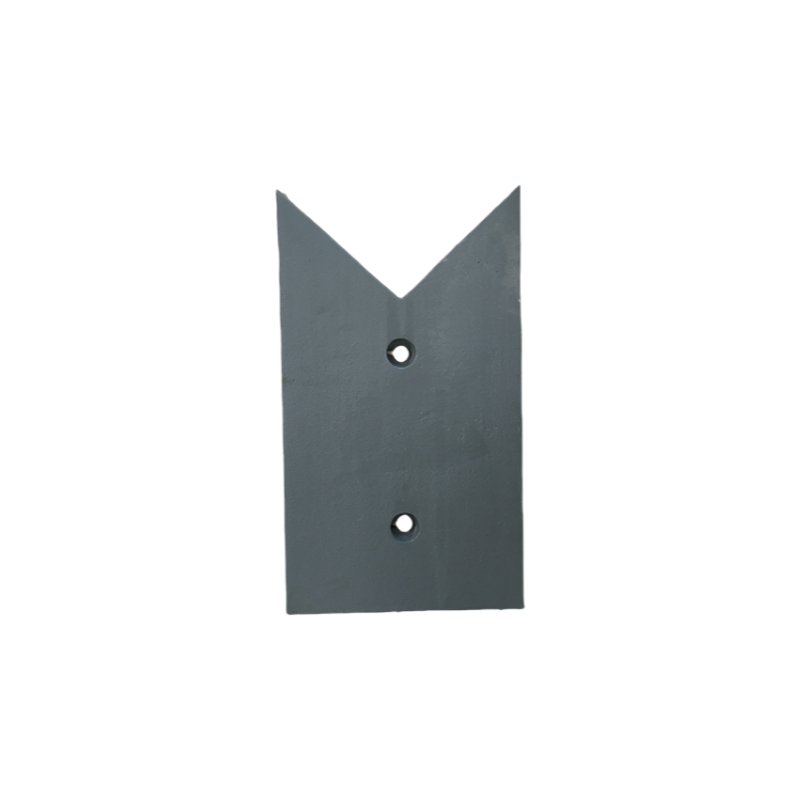

Concrete Mixing plant High-precision Scraper

-

Scraper-Concrete Mixing Plant

-

High Toughness Scraper For Concrete Mixing Plant

-

Concrete Mixing Plant Lining Plate

-

Concrete Mixing Plant High Wear-resistant Lining Plate

-

Good Toughness Lining Plate

-

Strong Wear Resistance Lining Plate

-

High Temperature Resistance Plate

-

Good Strength Lining Plate

-

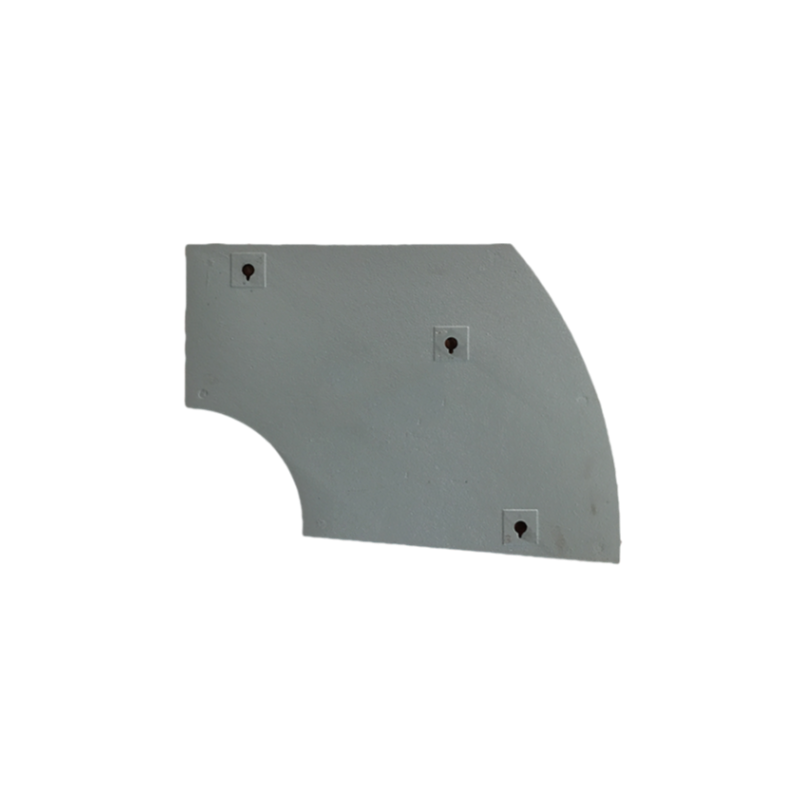

Lining Plate For Asphalt Mixing Plant

-

Lining Plate-Asphalt Mixing Plant

-

Asphalt Side Lining parts

-

Asphalt Machinery Series

-

Mixing Arm-Asphalt Mixing Plant

-

Spiral Blade For Asphalt Mixing Plant

-

Sealing element-Asphalt Mixing Plant

-

Scraper-Asphalt Mixing Blade

-

Spiral Blade-Asphalt Mixing Plant

-

Asphalt Side Lining

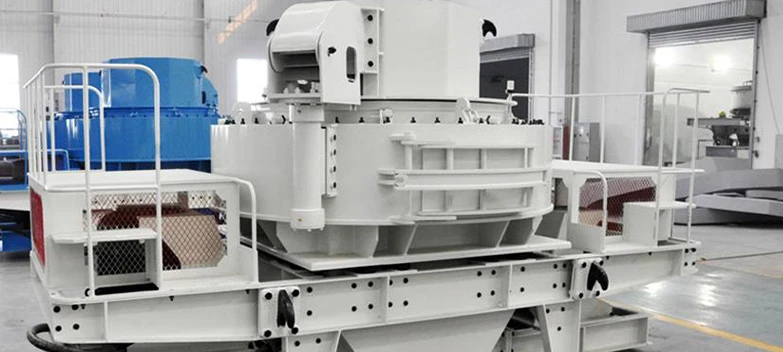

Target Industries

-

Concrete Equipment

-

Pavement Mechanical Equipment

-

Mining Equipment

-

Metallurgical Equipment.

Key Advantages

1. Workload Matching & Structural Optimization

Our engineering team conducts in-depth analysis of the customer's working conditions, including wear patterns, operating temperatures, and impact frequency. Based on mechanical principles, we optimize structural design and stress distribution to significantly extend product lifespan.

2. Material Engineering & Heat Treatment Tailoring

We offer a wide selection of materials such as high-chromium cast iron, high-manganese steel, alloy steel, and Ni-hard white iron. Tailored heat treatment plans are developed based on application environments to ensure the optimal balance of hardness and toughness.

3. Drawing Modeling & Rapid Prototyping

We support both 2D drawings and 3D modeling, and can also reverse engineer from physical samples. Our streamlined mold-making and sample production process helps reduce product development lead time by 30%–50%.

4. Full-Process Quality Control & Timely Delivery

From raw material inspection to final machining, every step is traceable and quality-controlled. With a digitalized manufacturing process and a dedicated delivery team, we ensure your custom parts are produced with accuracy and delivered on time.

5. Dedicated Engineering Support & Service Assurance

We provide full technical evaluations, application feedback analysis, and continuous optimization advice. Global remote support and integration with local partners ensure responsive and reliable after-sales service.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tel:

Tel:  Fax: 0555-6971198

Fax: 0555-6971198 Website:

Website:  Email:

Email:  Postal code: 243141

Postal code: 243141 Address: Xinshi Industrial Park, Bowang District, Ma’anshan City, Anhui Province, China

Address: Xinshi Industrial Park, Bowang District, Ma’anshan City, Anhui Province, China

Tik Tok

Tik Tok