INTRODUCTION

The advantages of 3D printing are mainly customized production, reduced waste, rapid prototyping, complex structures, and cost-effectiveness.

WEAR-RESISTANT PARTS RELATED PRODUCTS

-

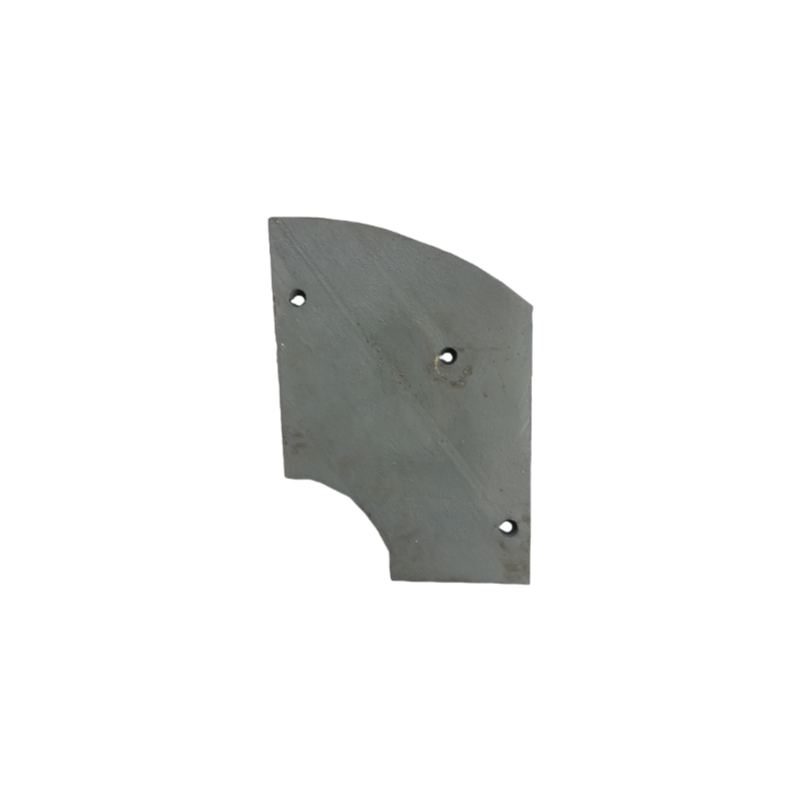

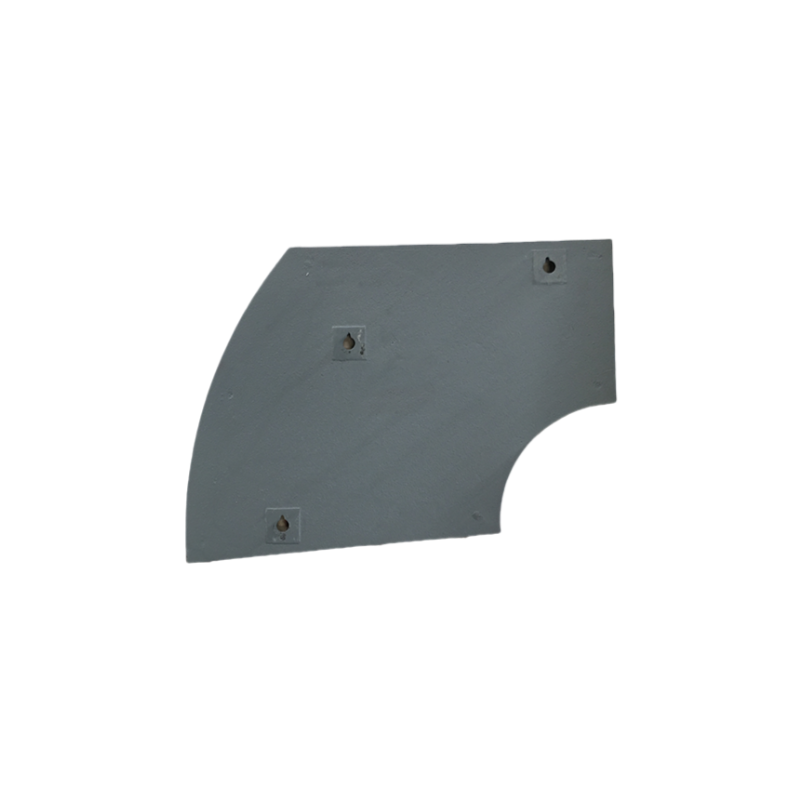

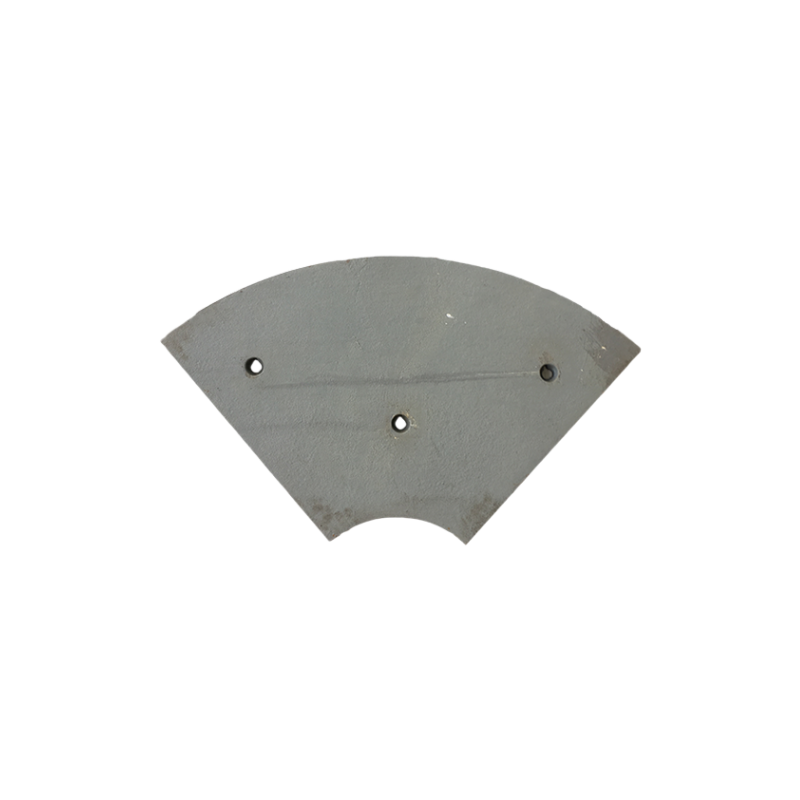

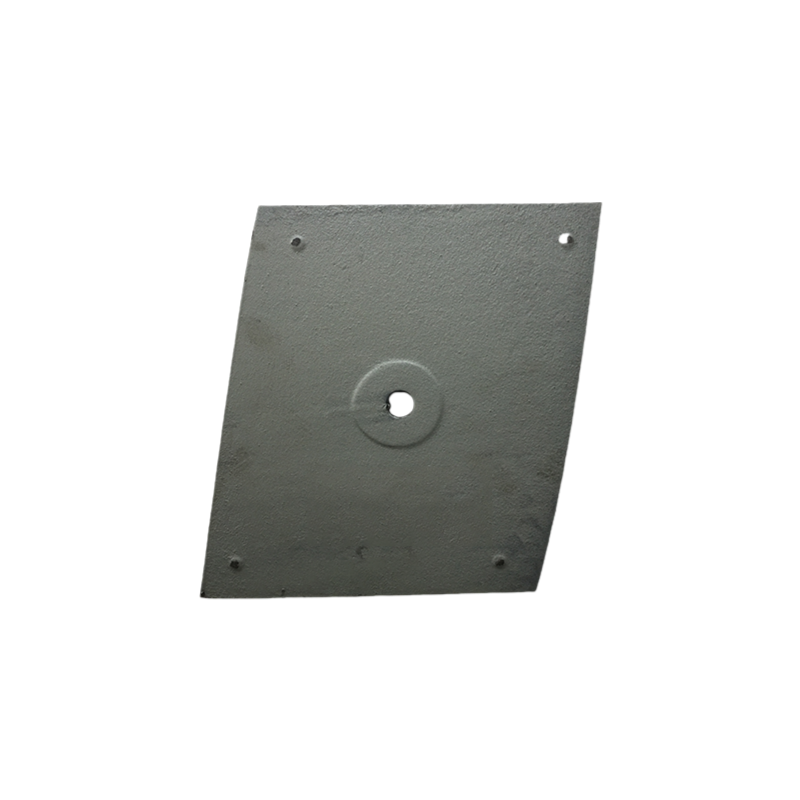

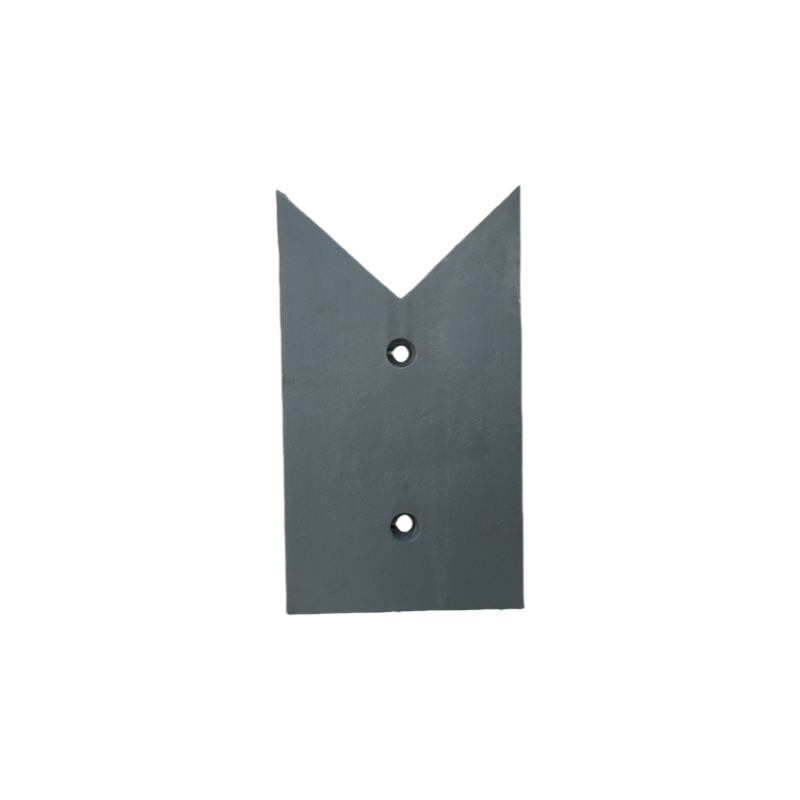

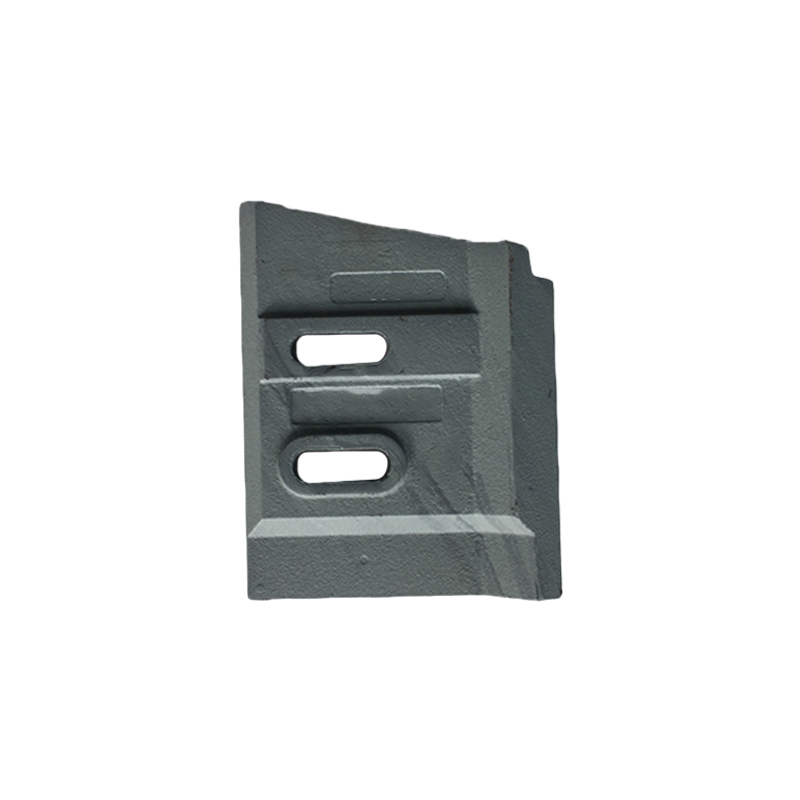

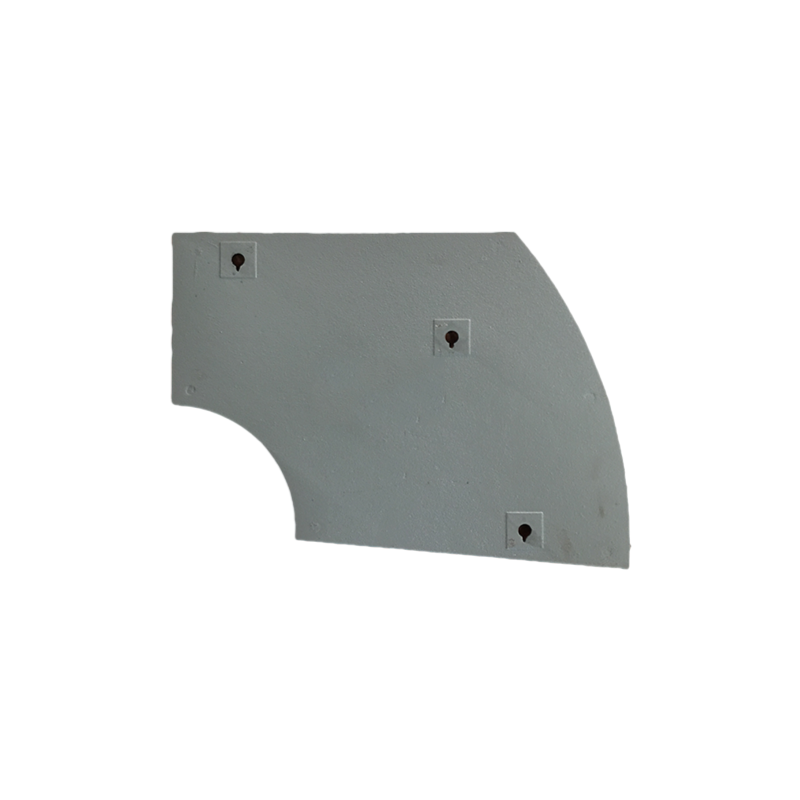

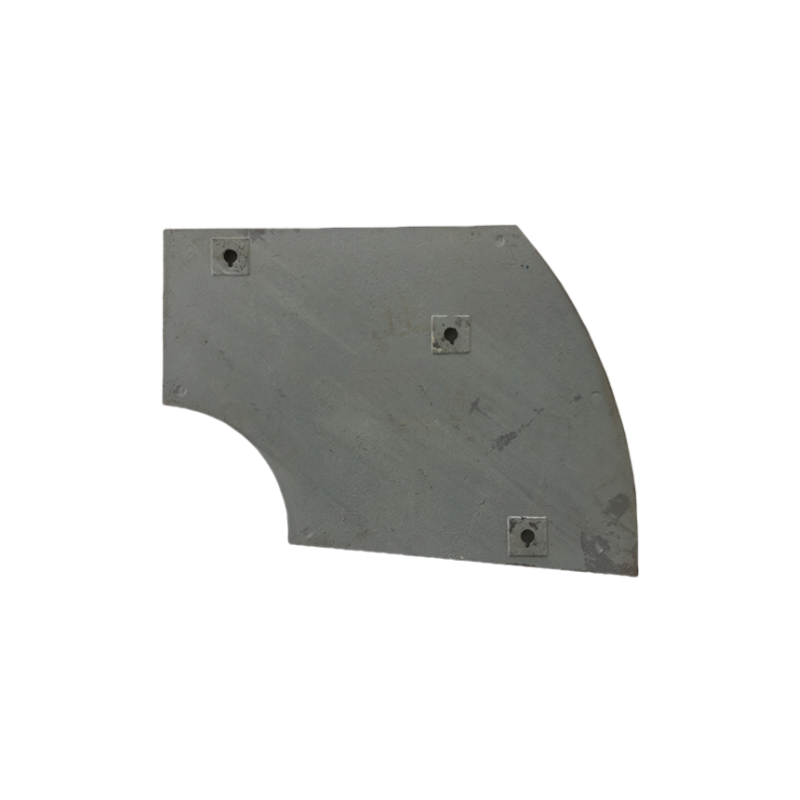

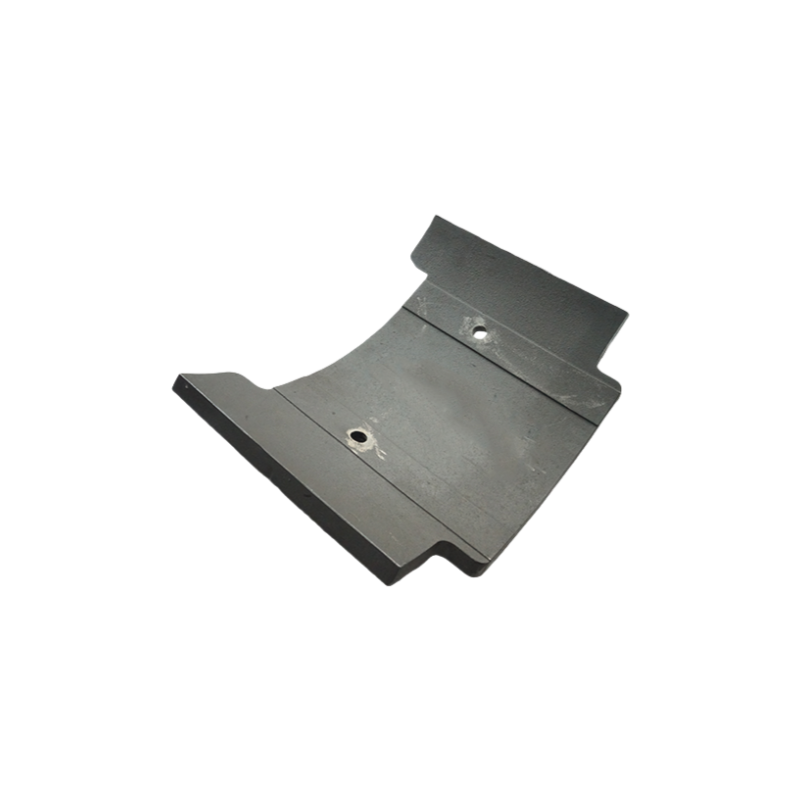

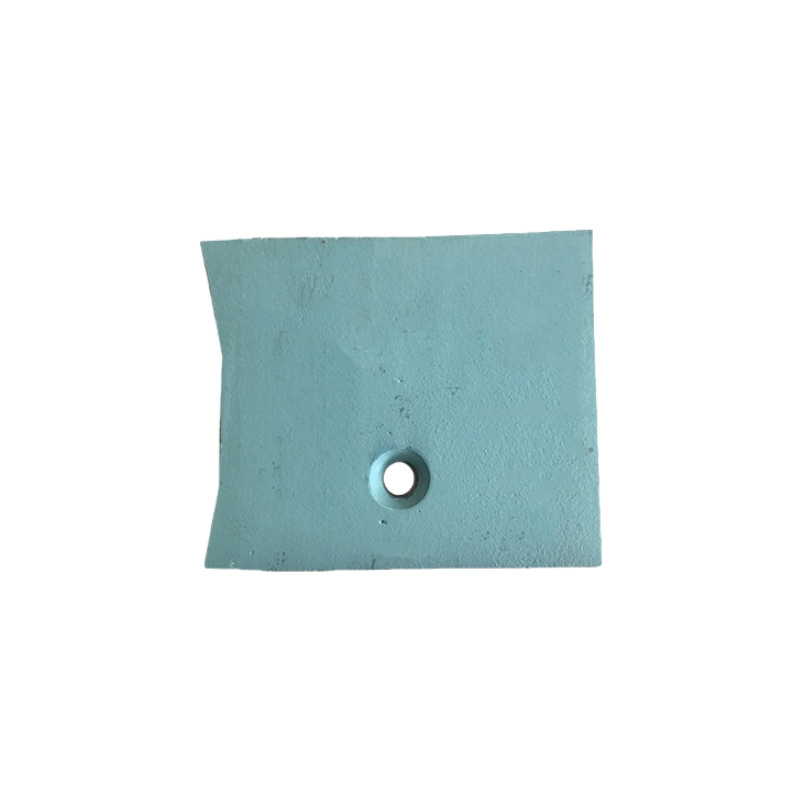

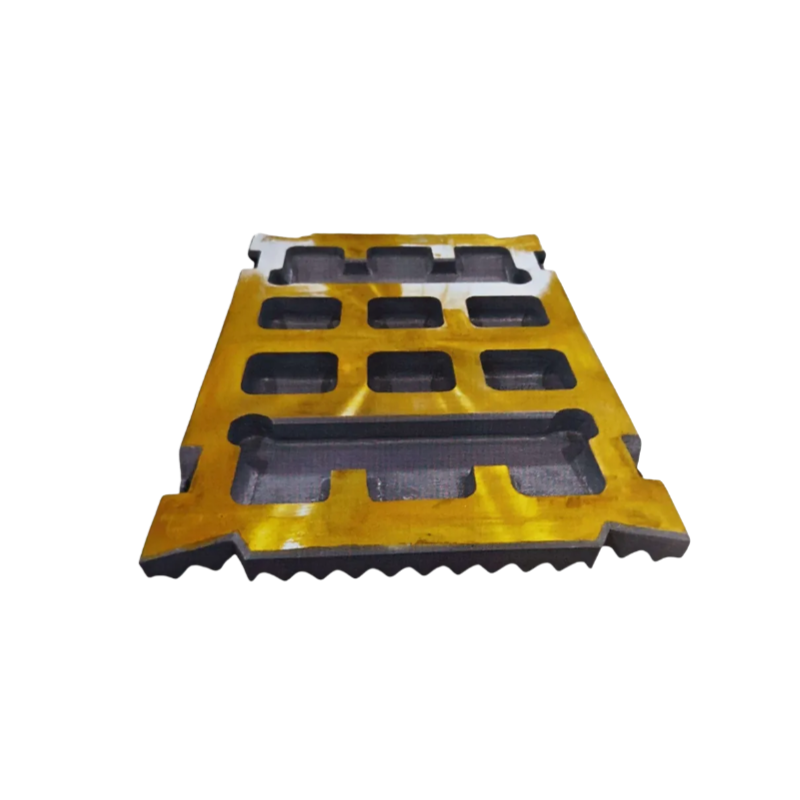

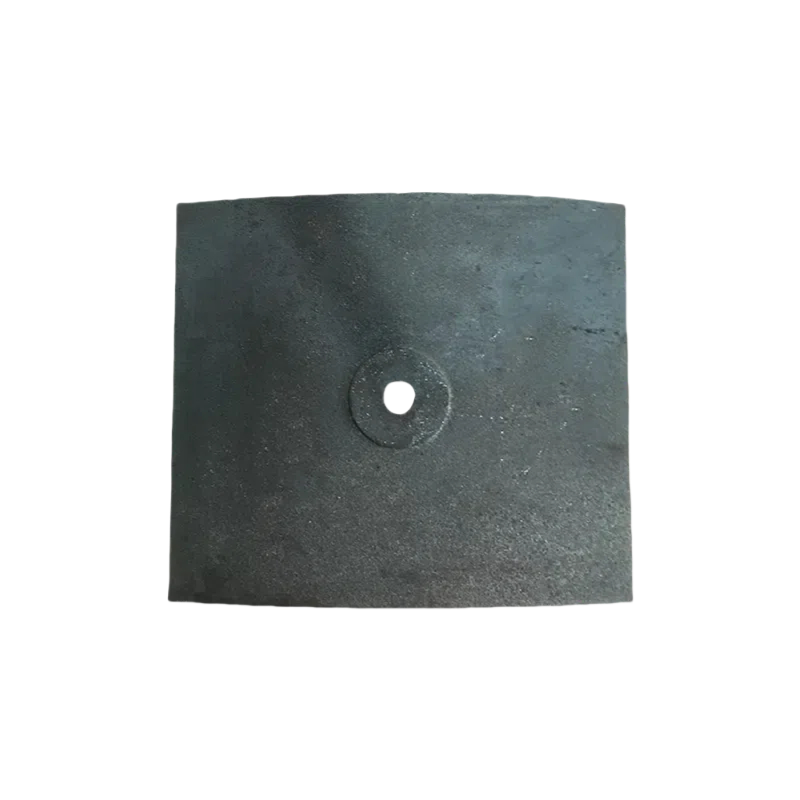

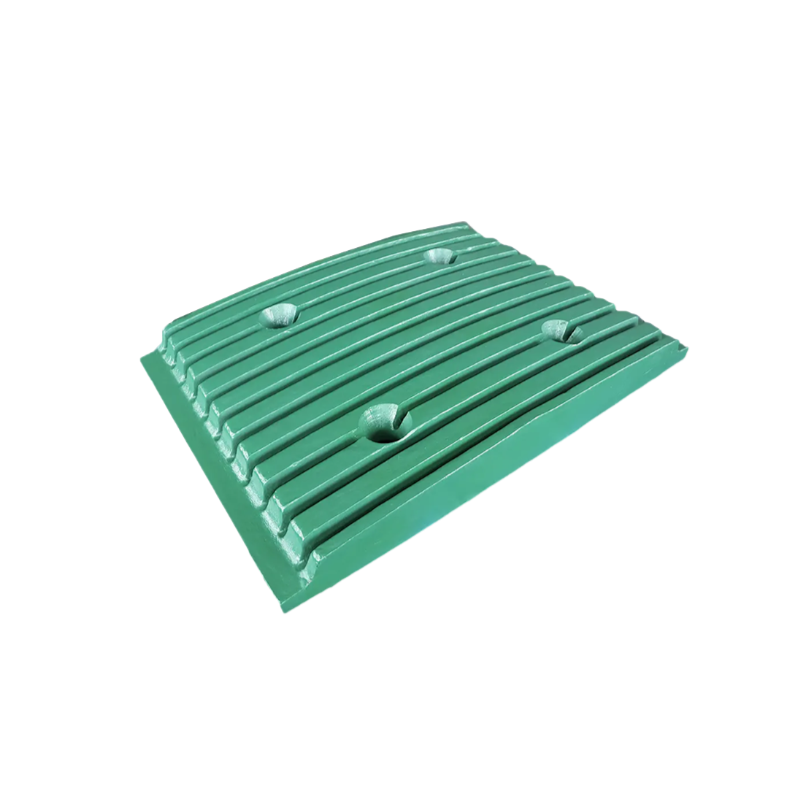

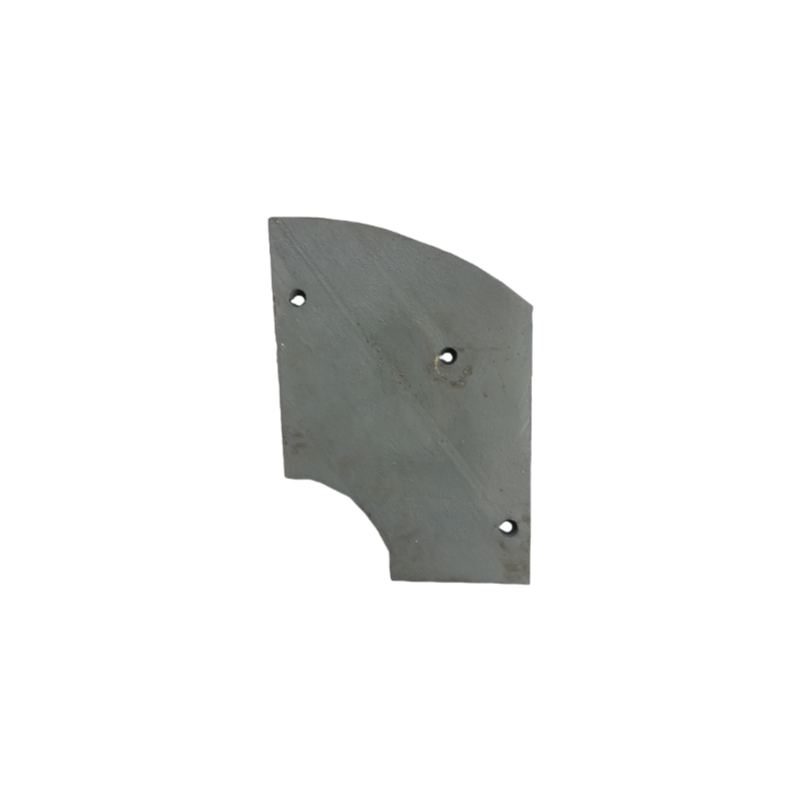

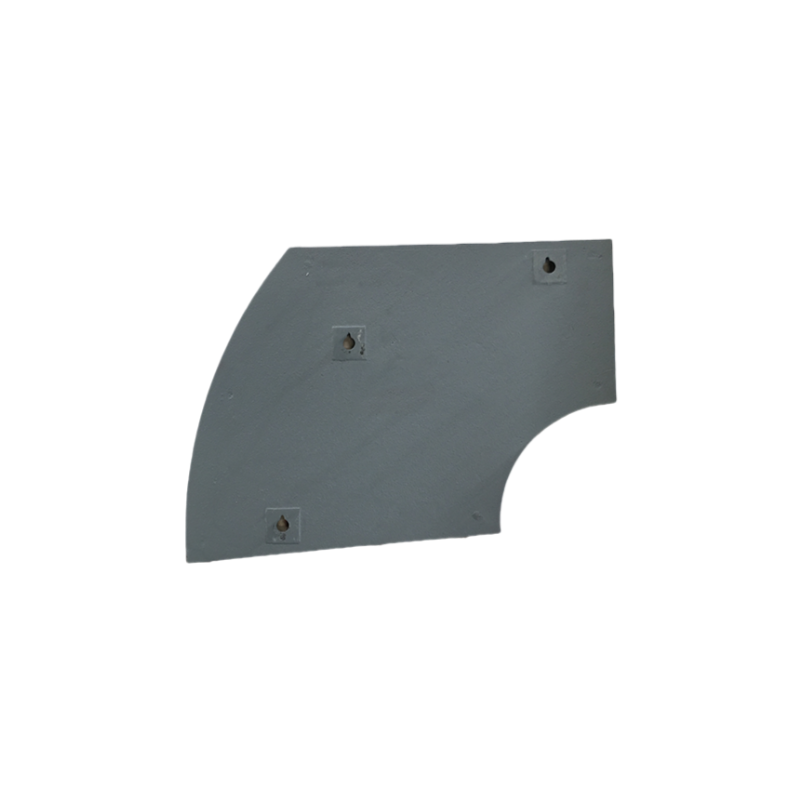

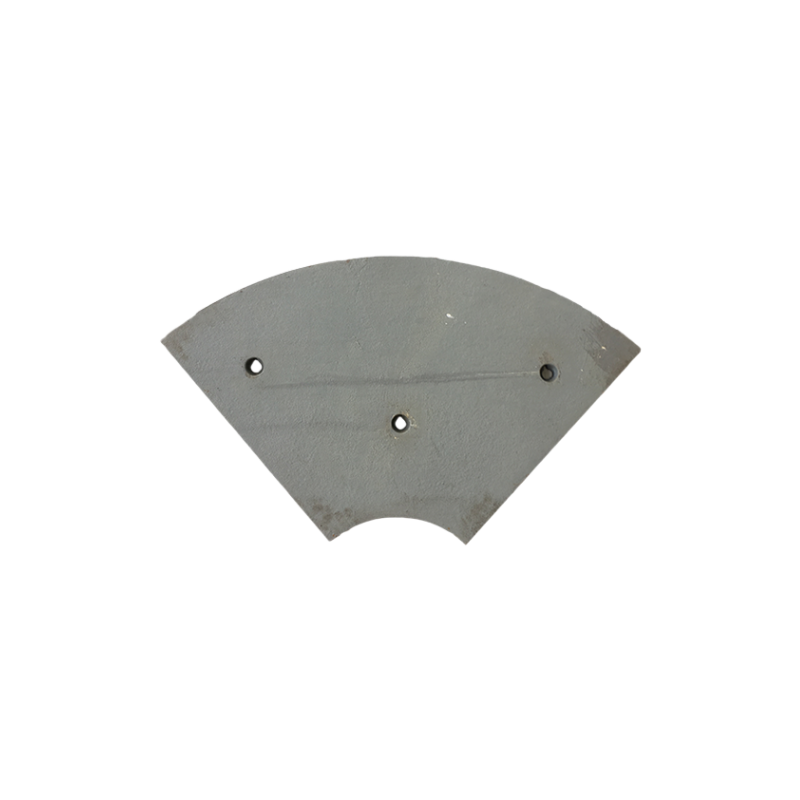

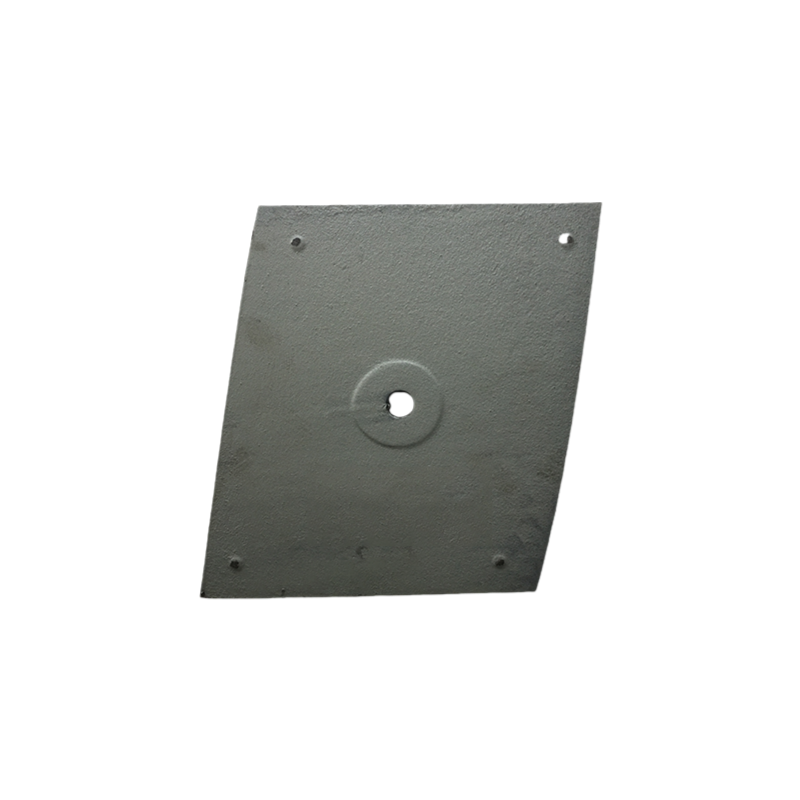

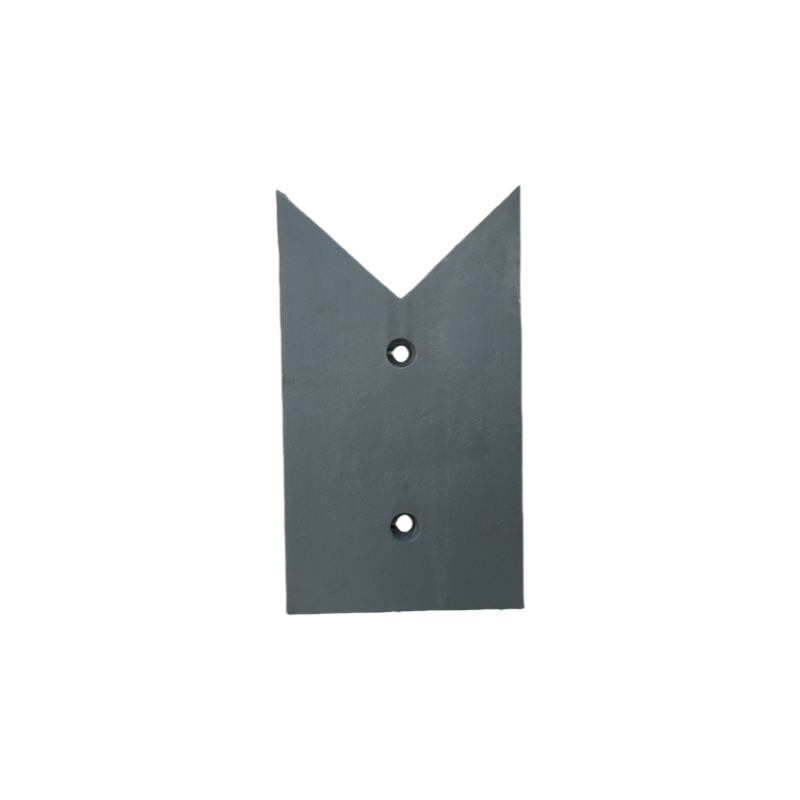

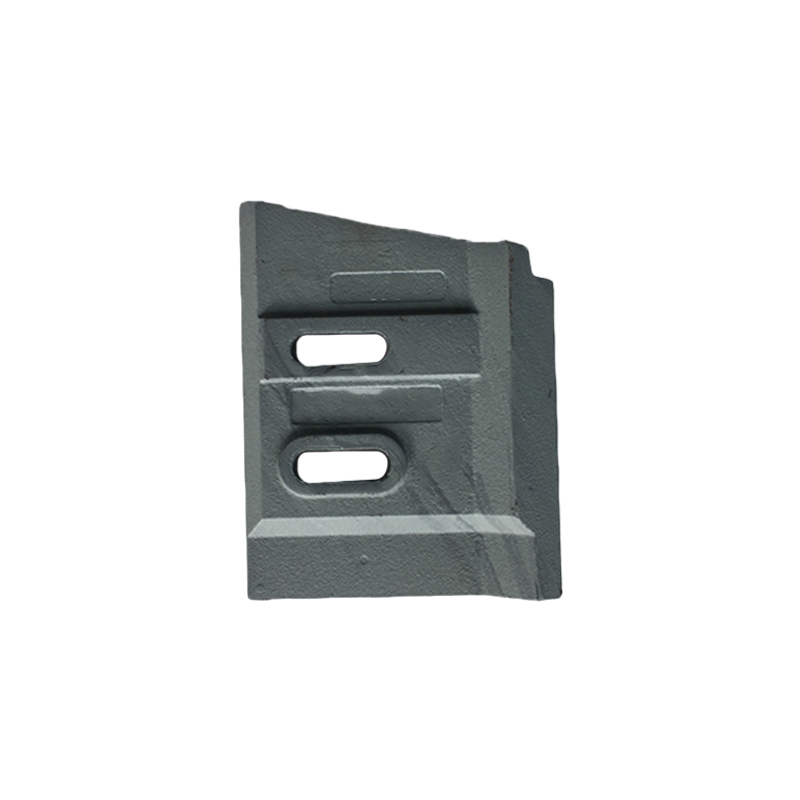

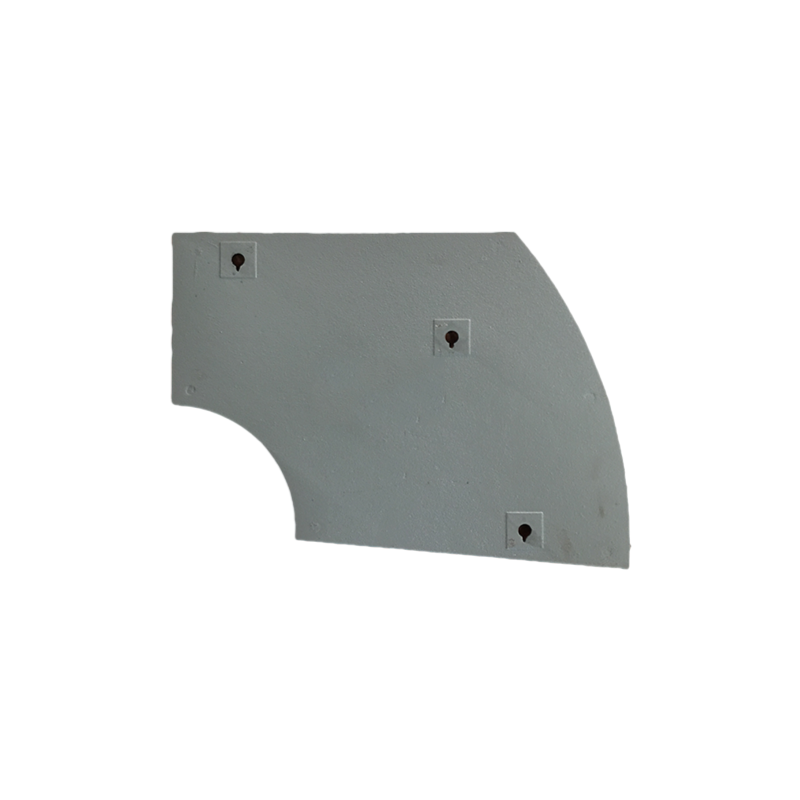

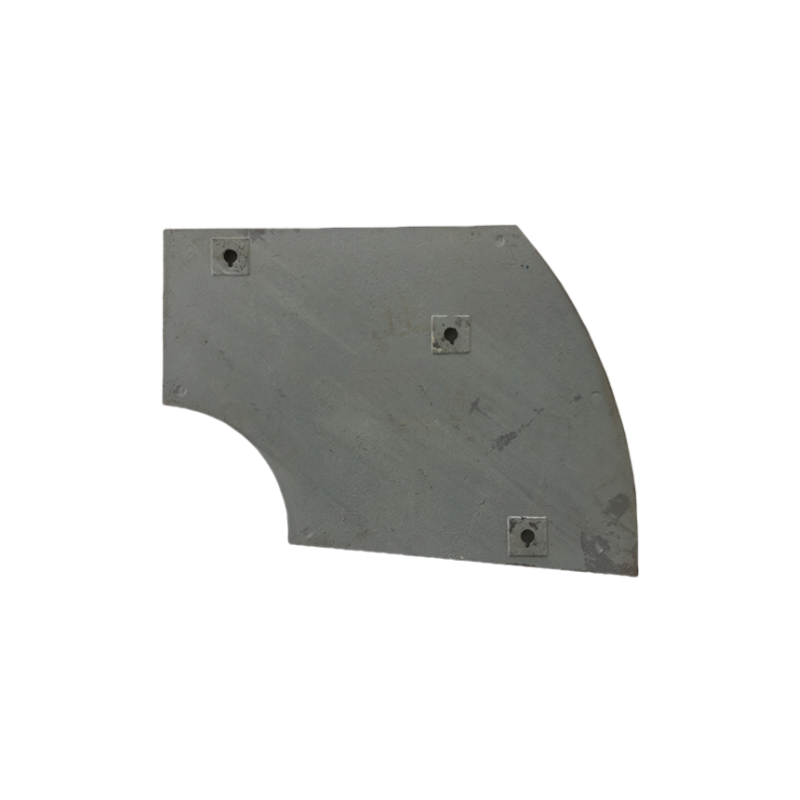

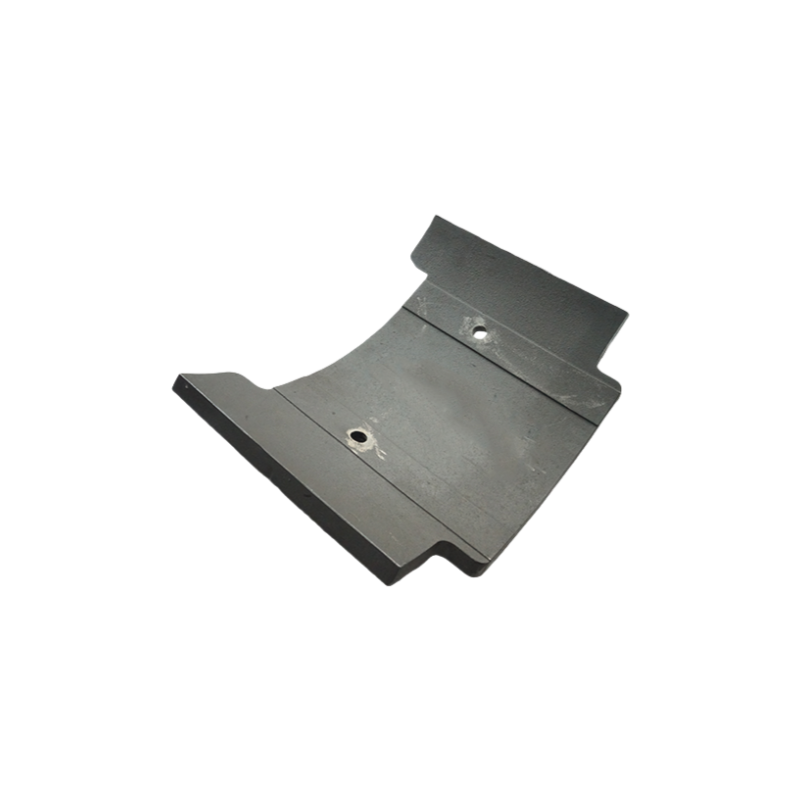

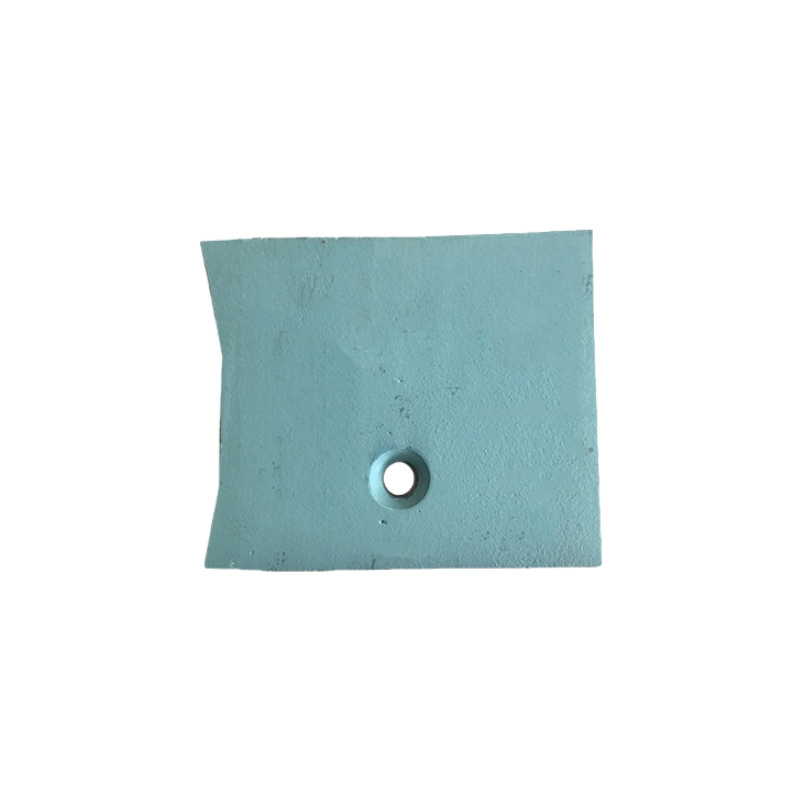

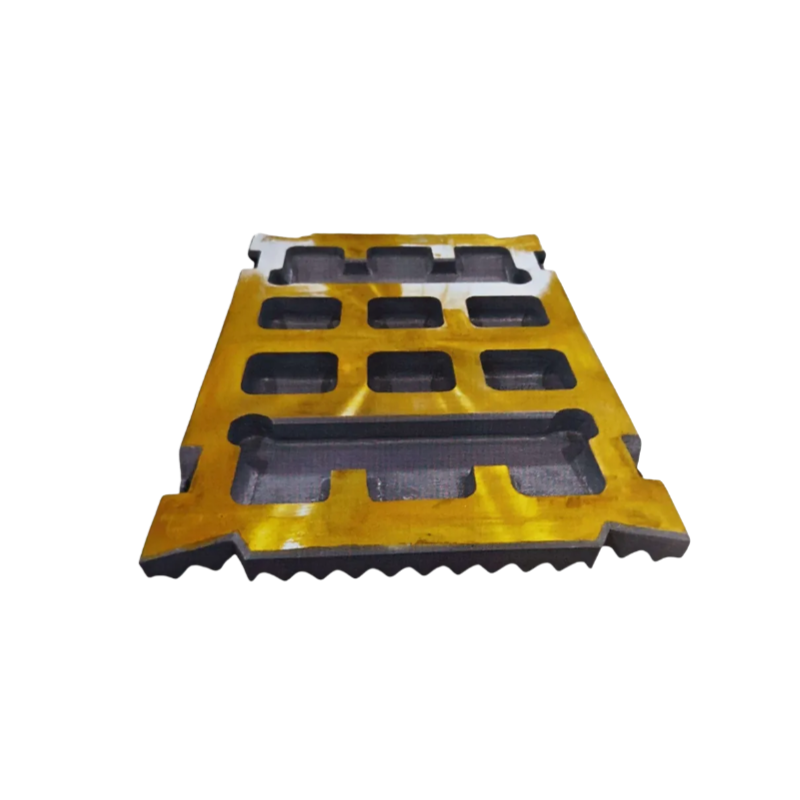

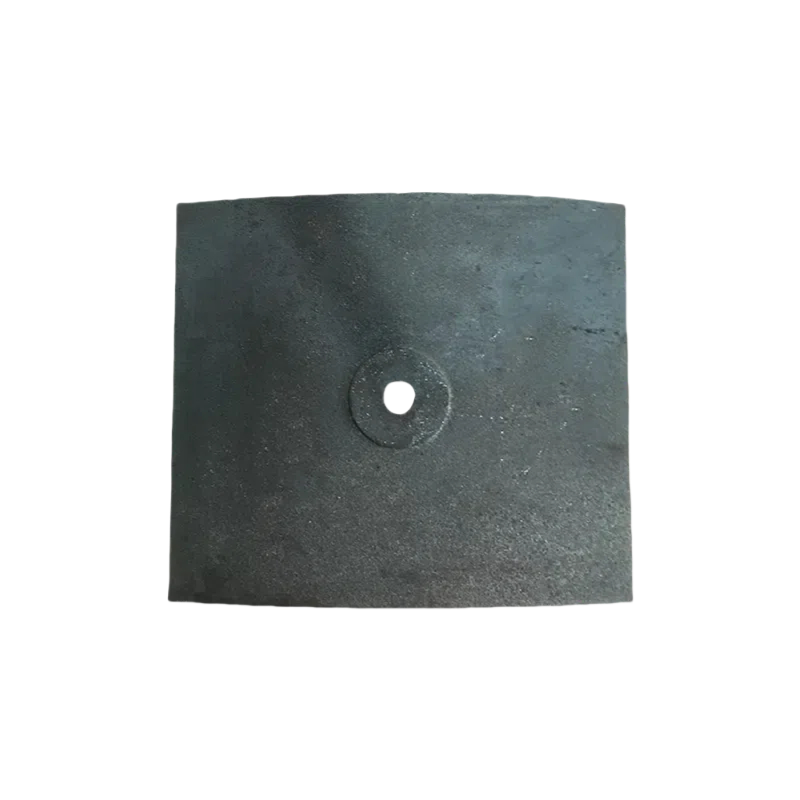

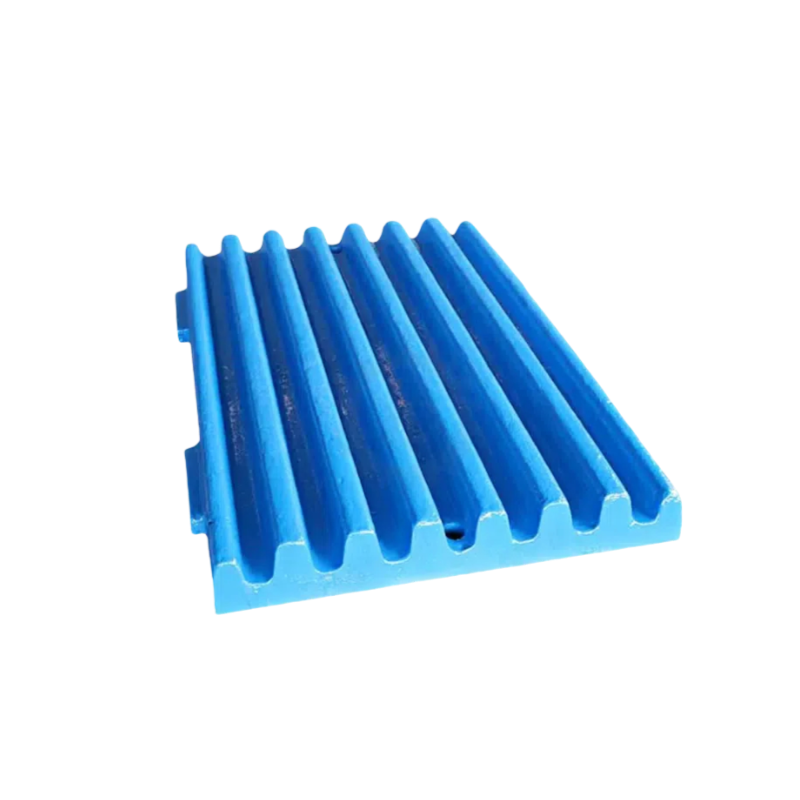

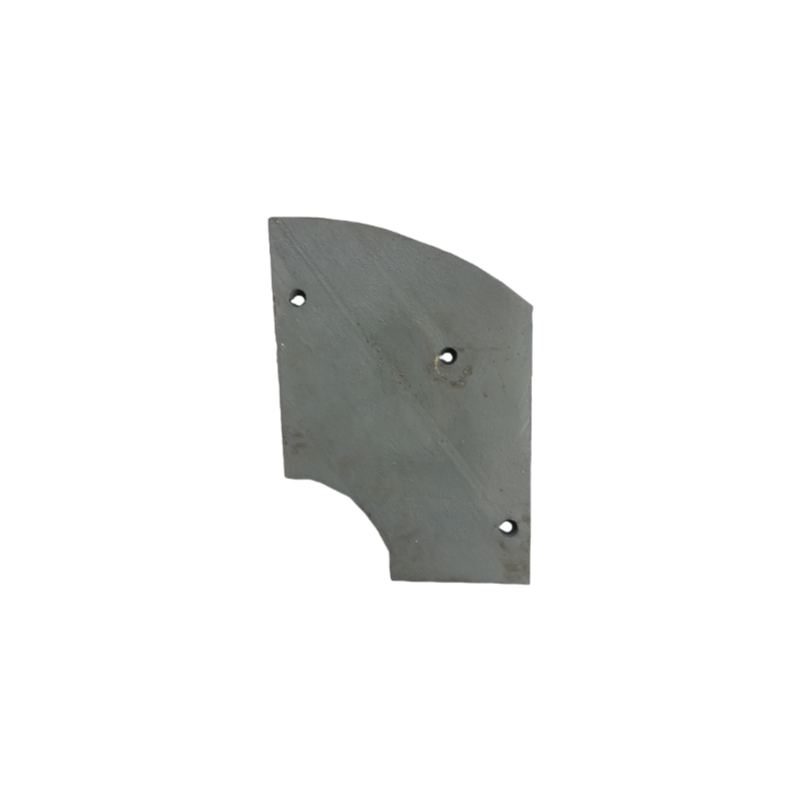

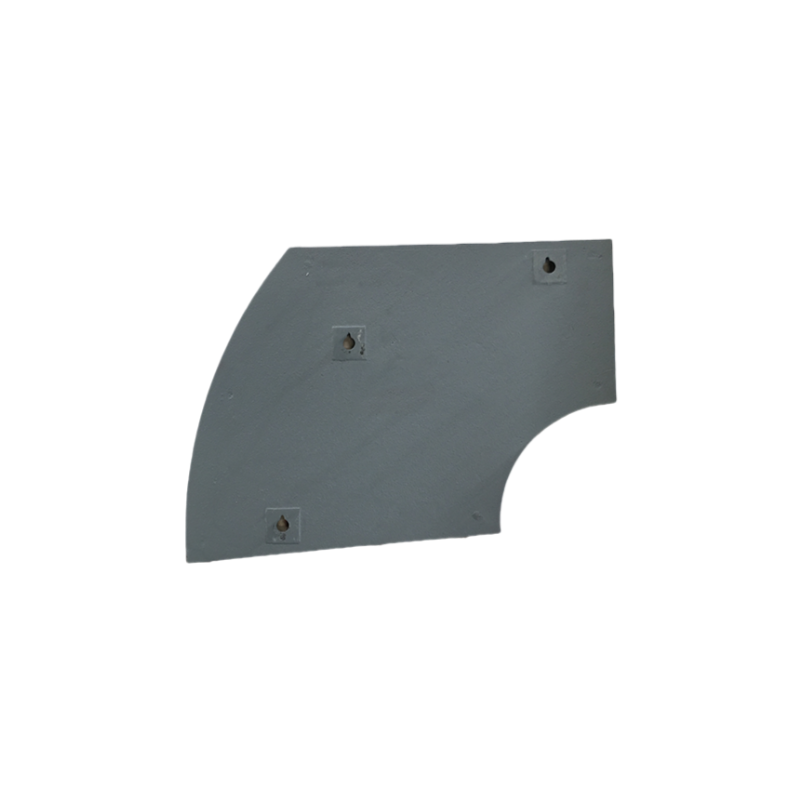

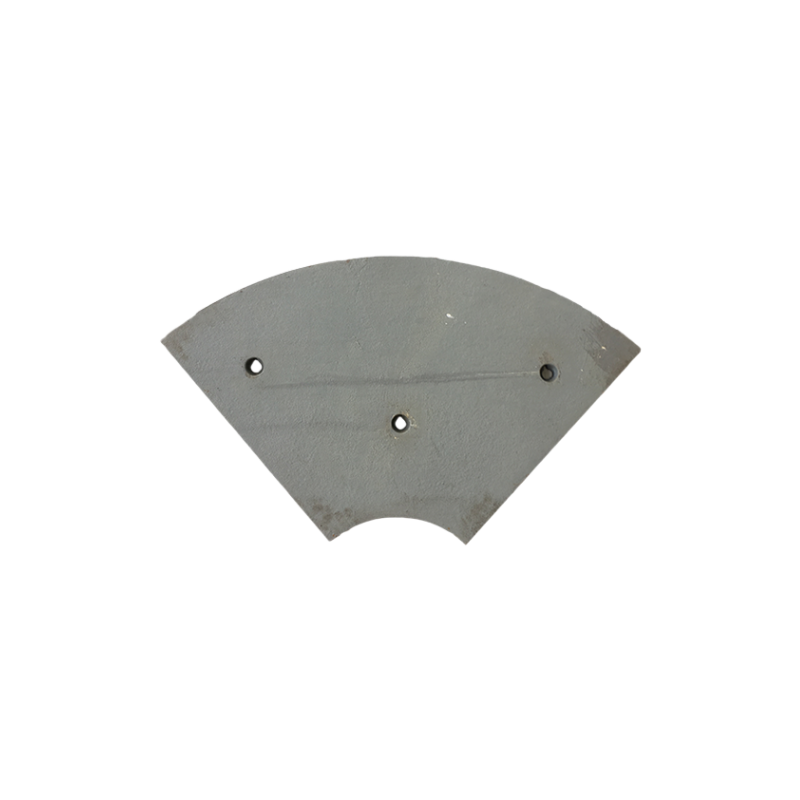

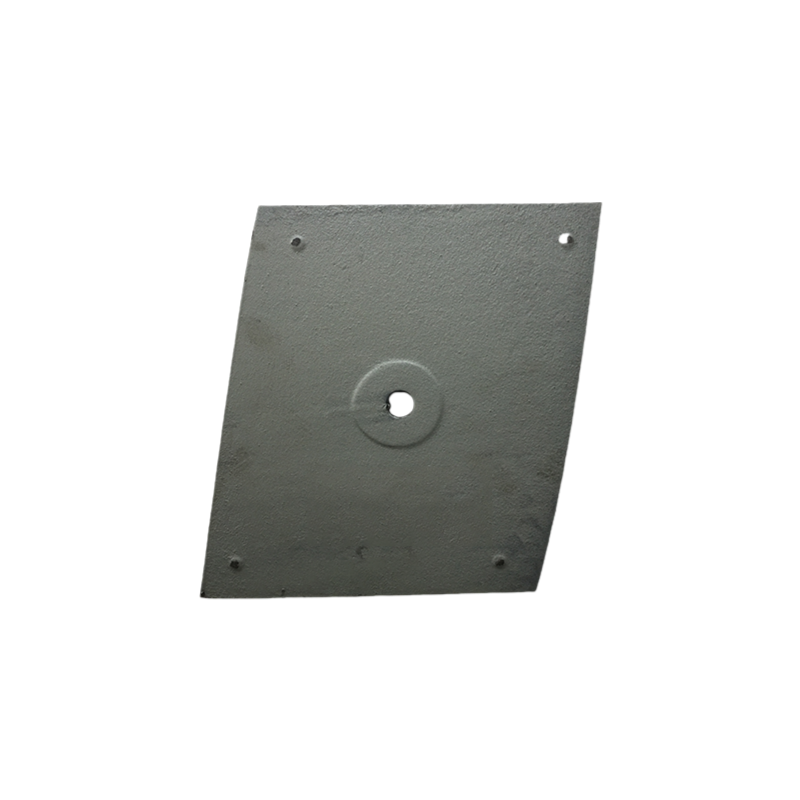

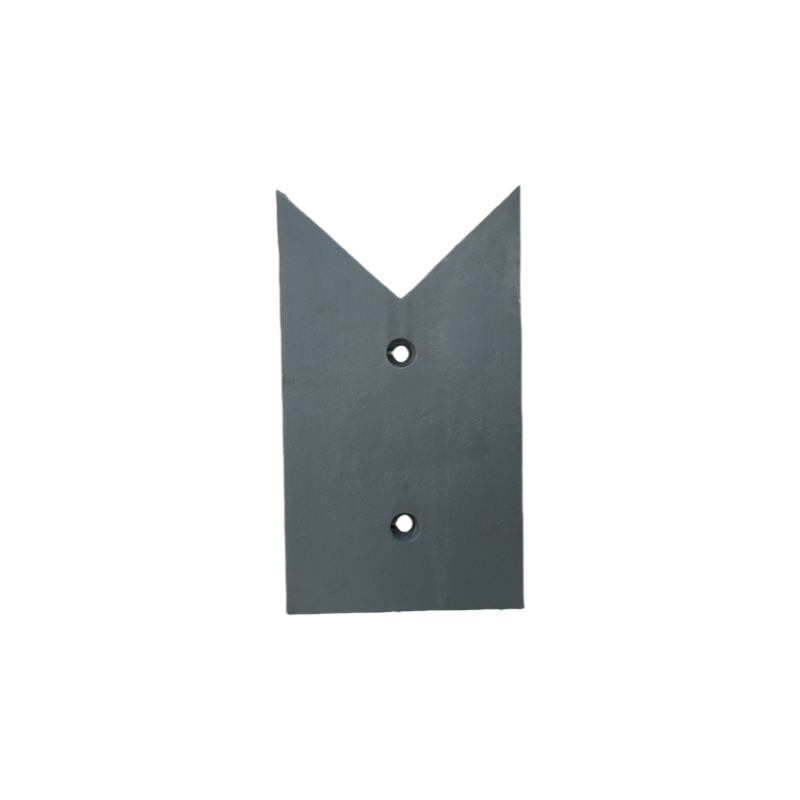

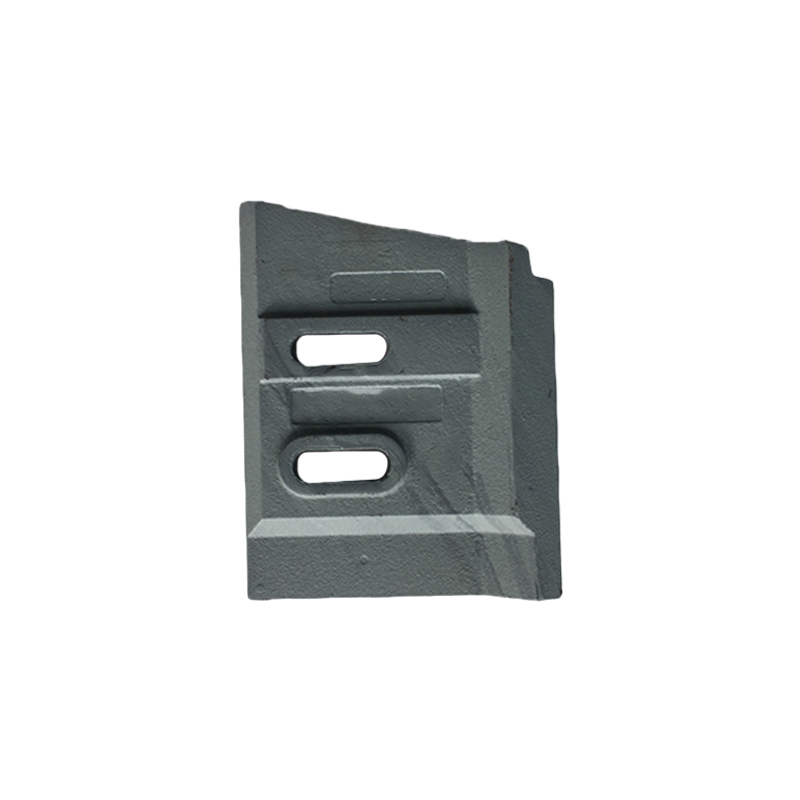

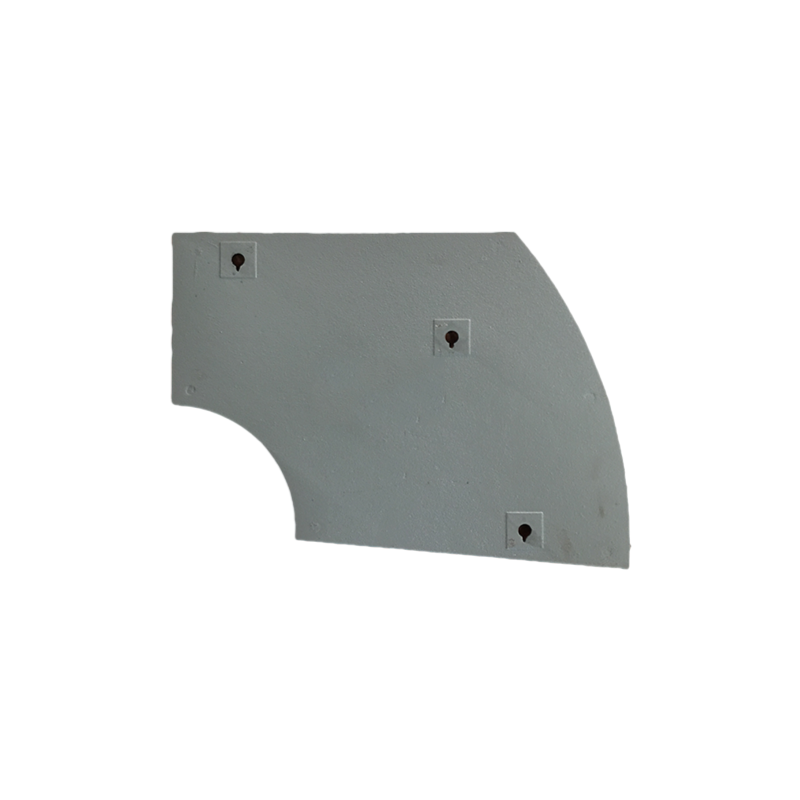

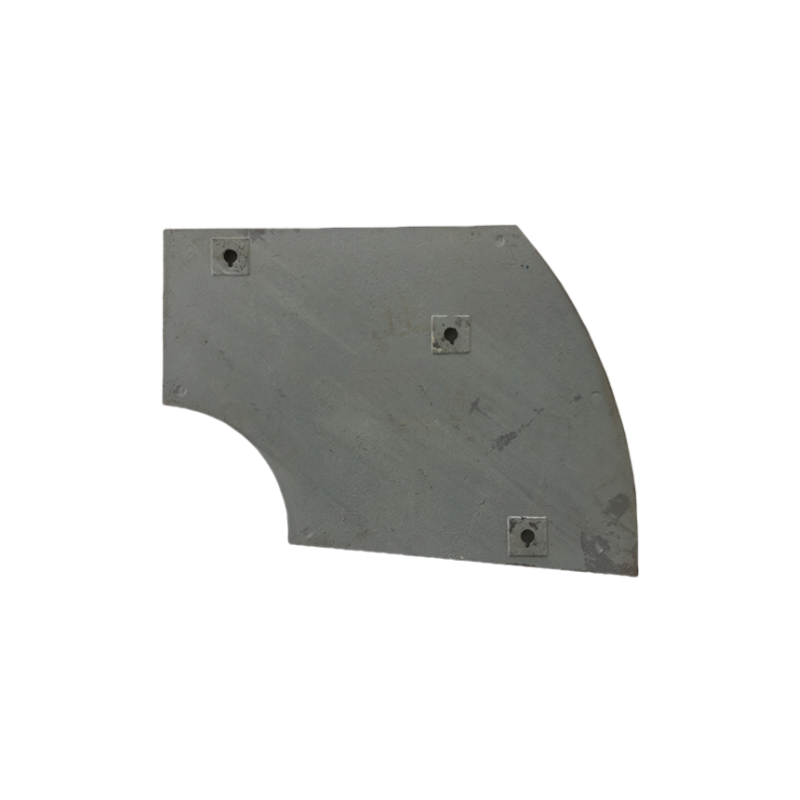

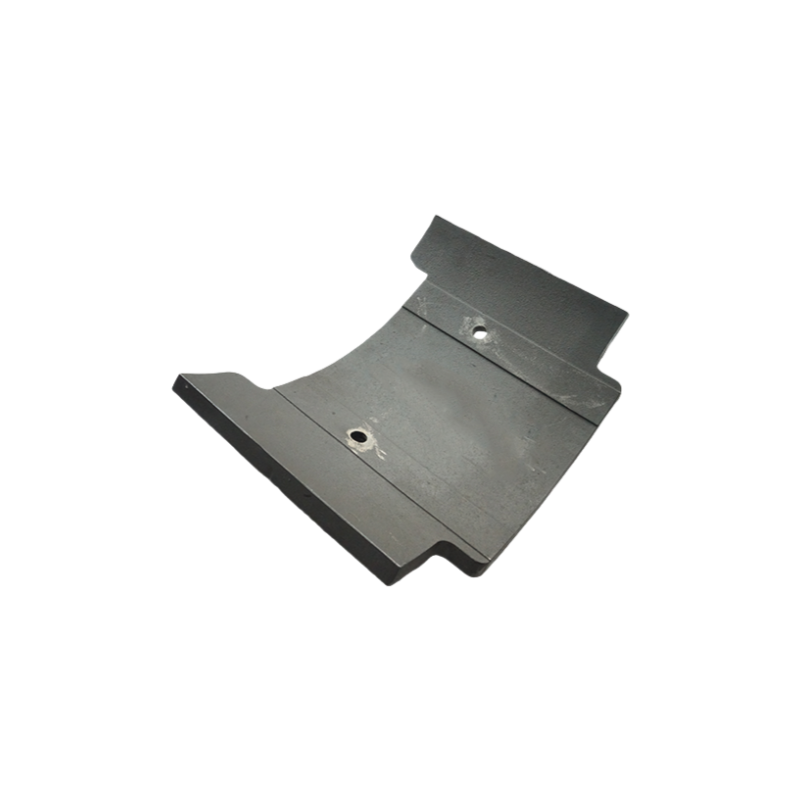

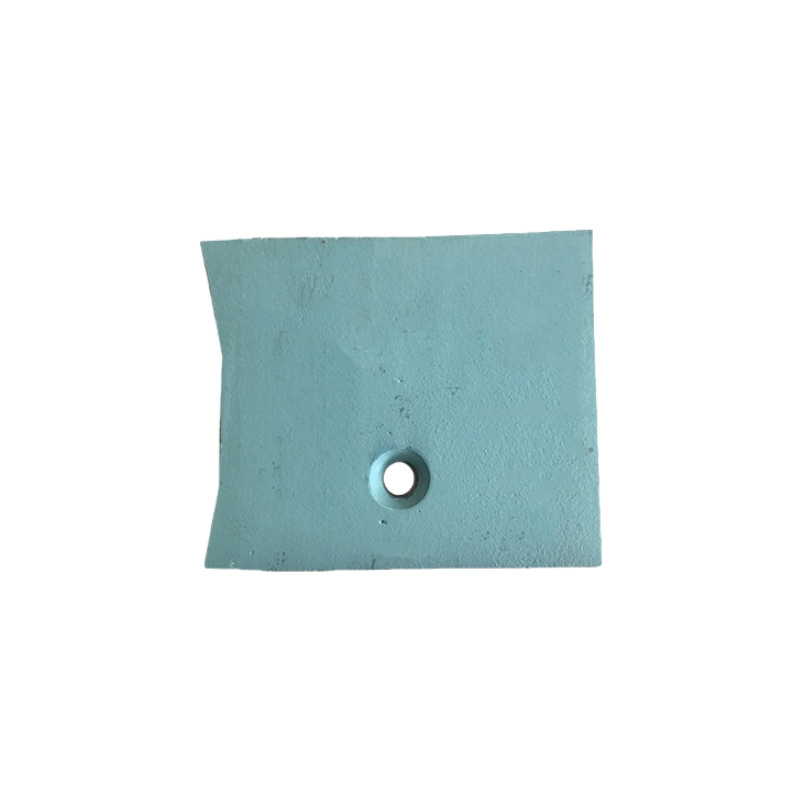

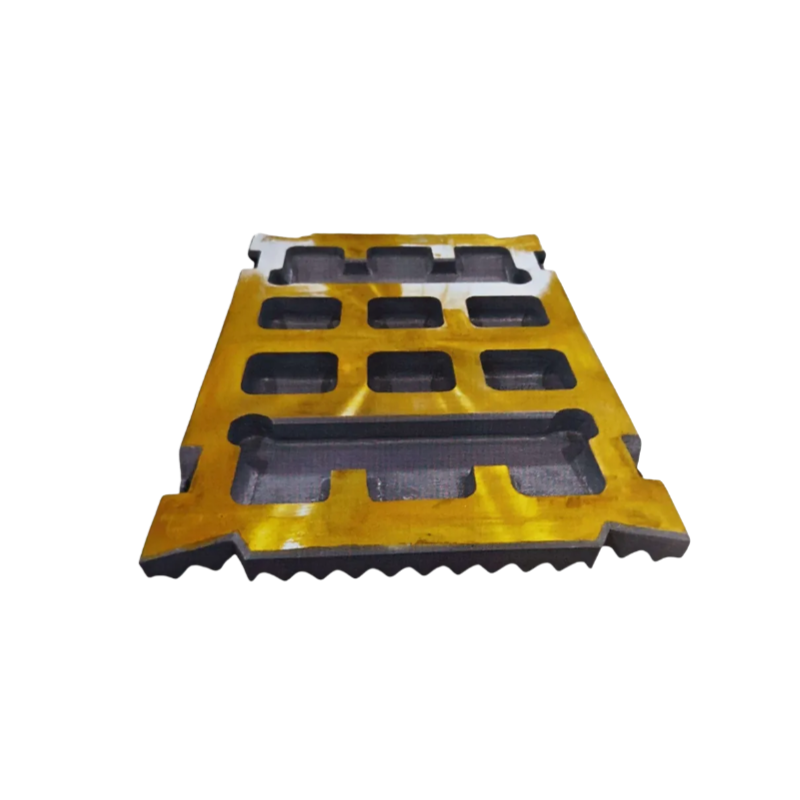

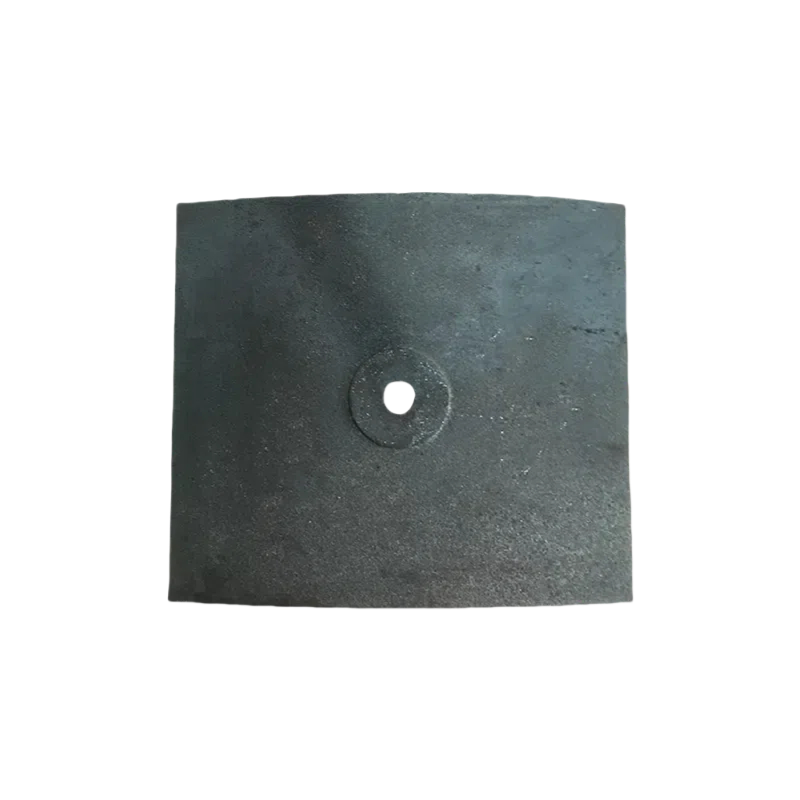

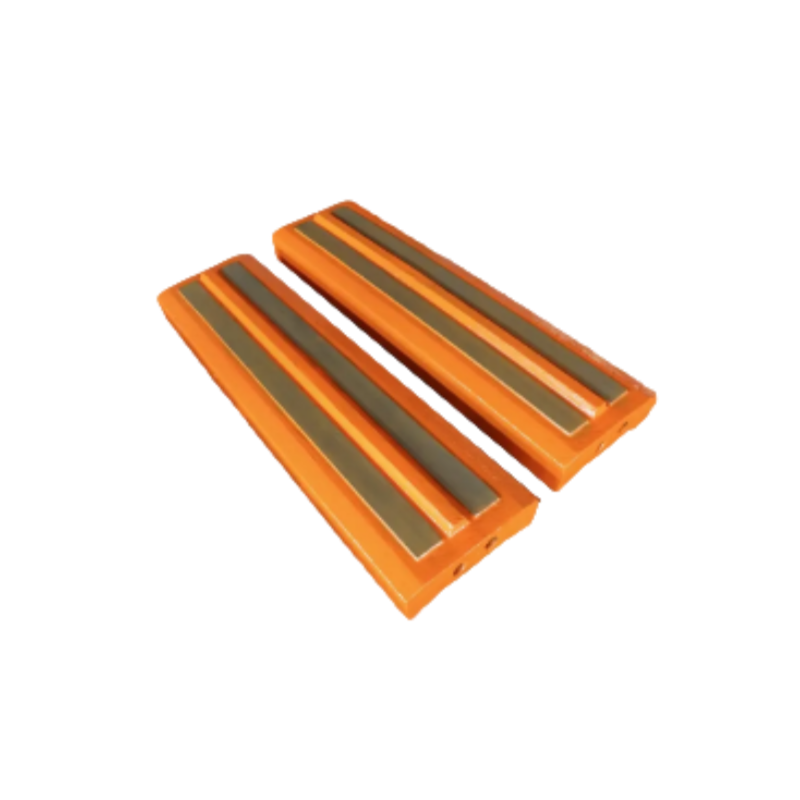

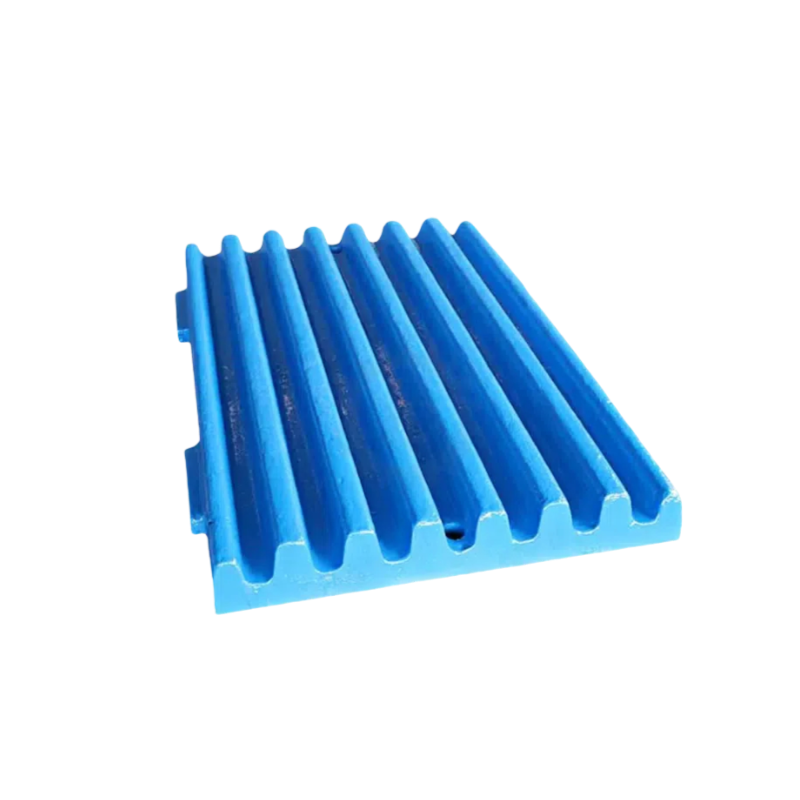

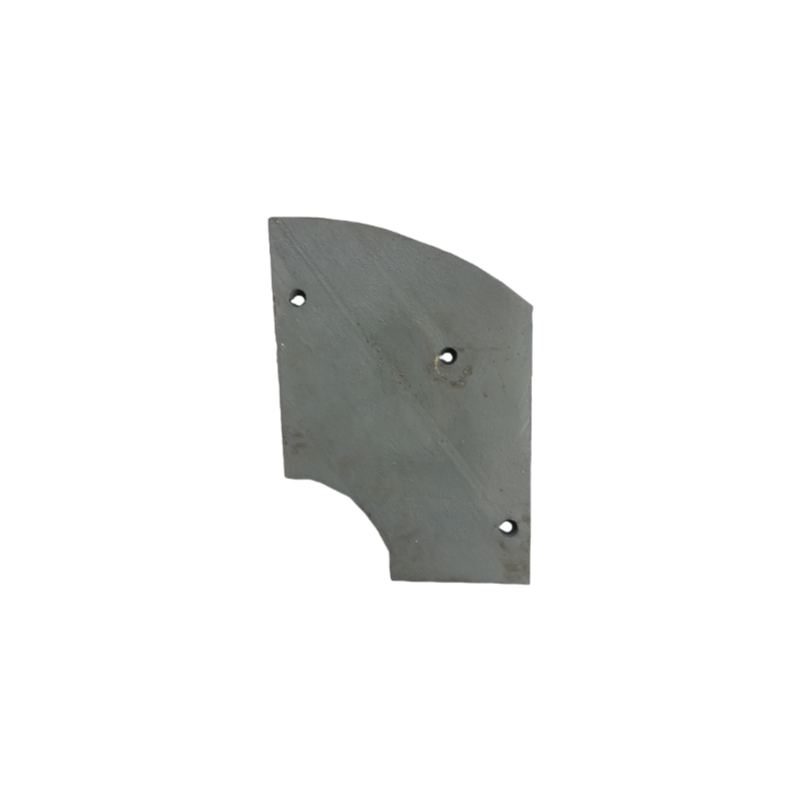

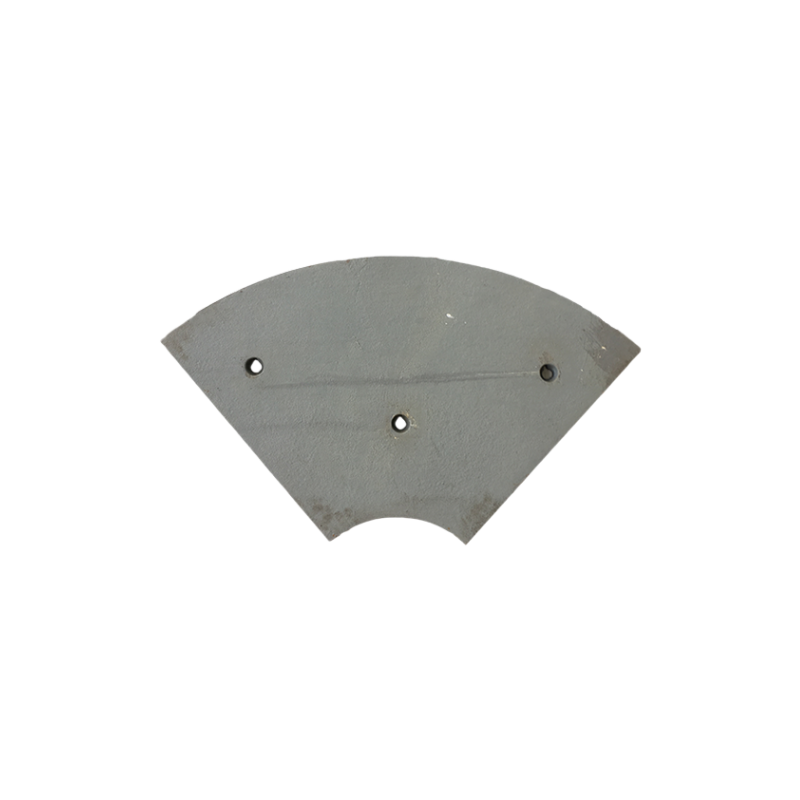

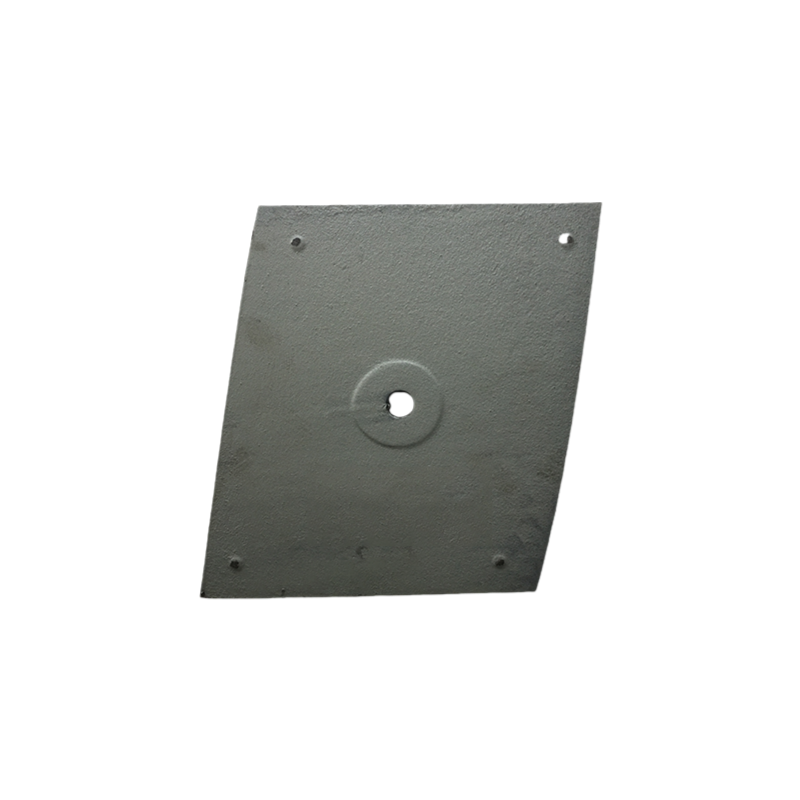

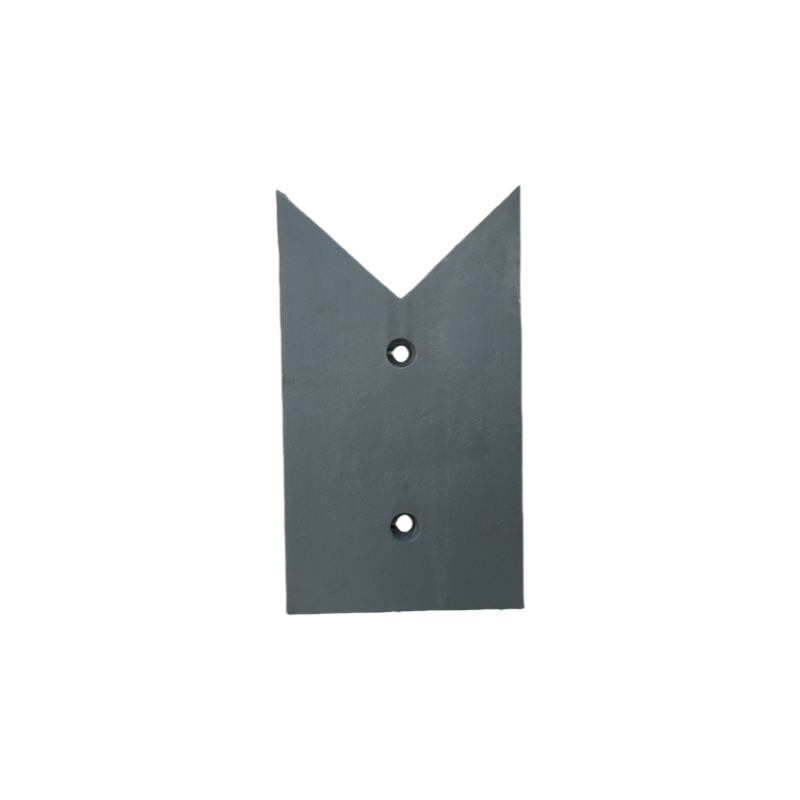

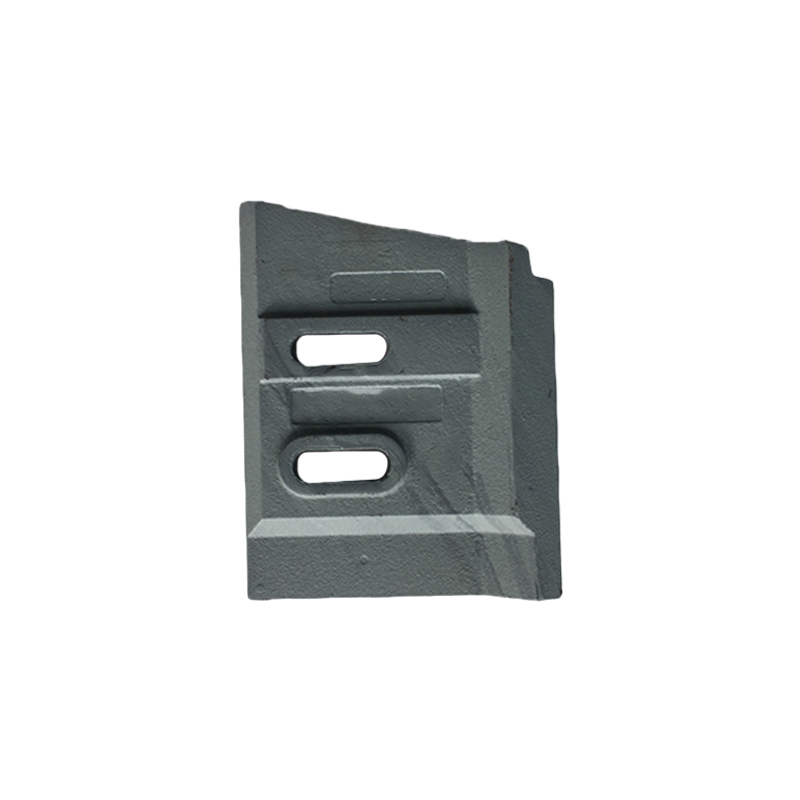

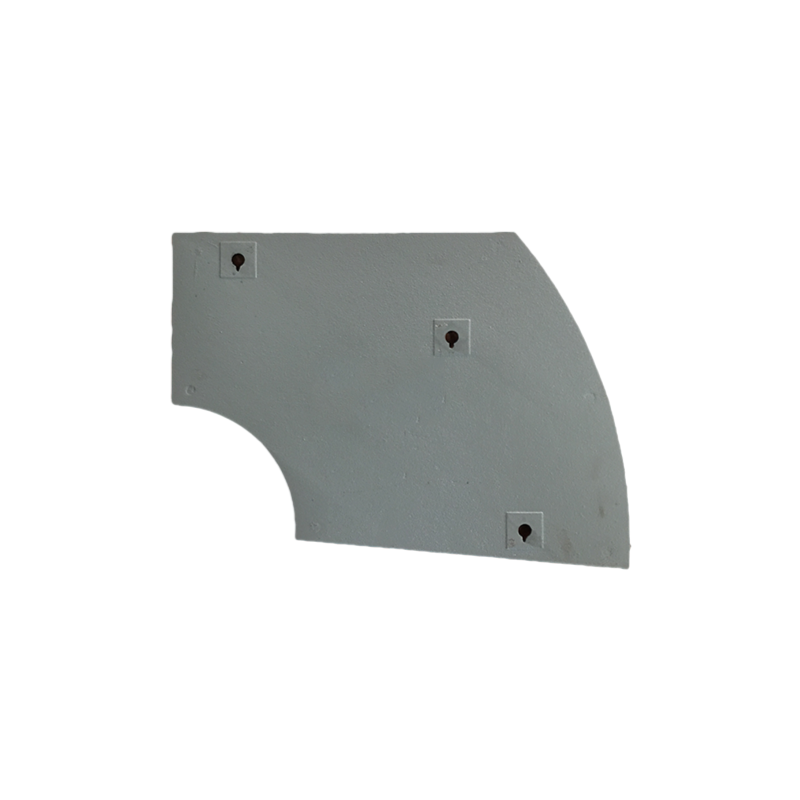

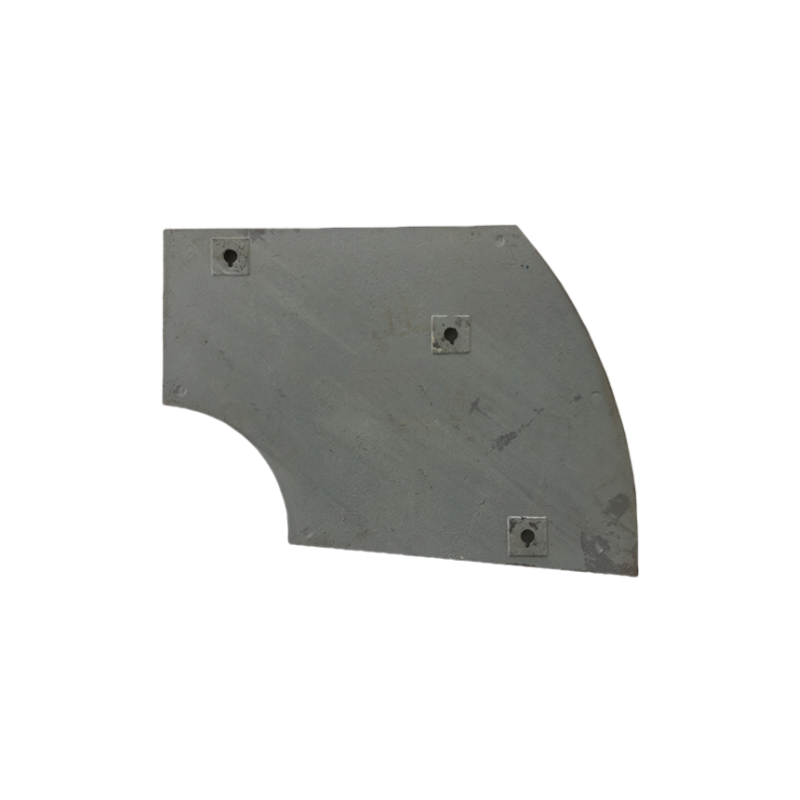

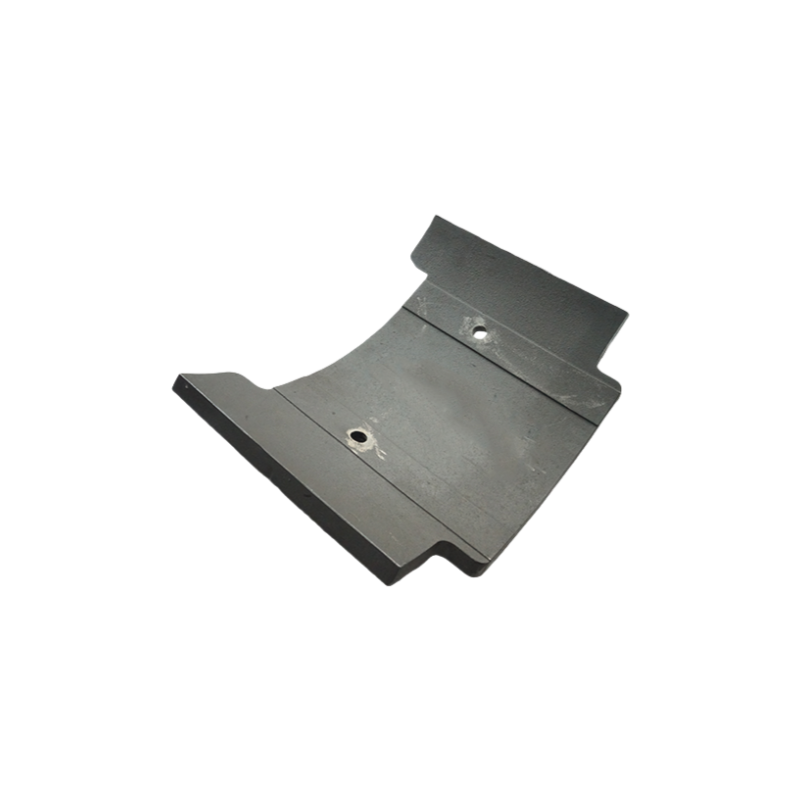

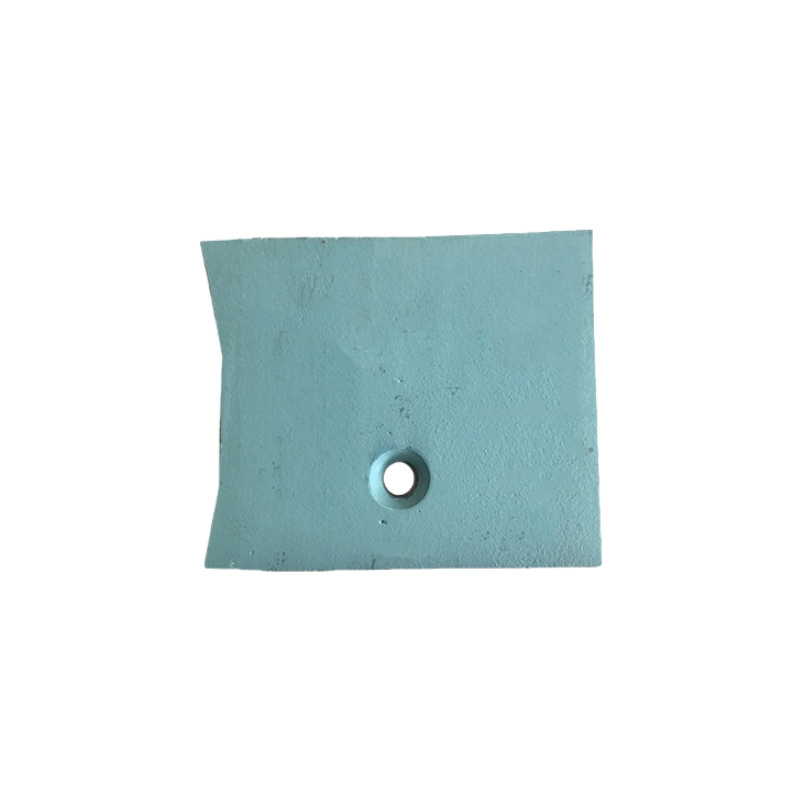

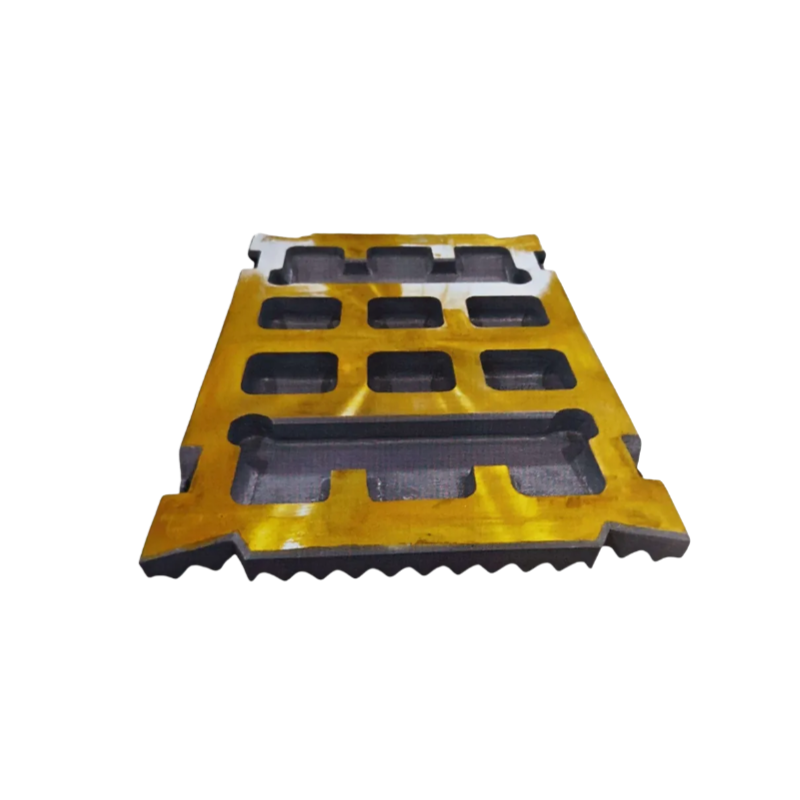

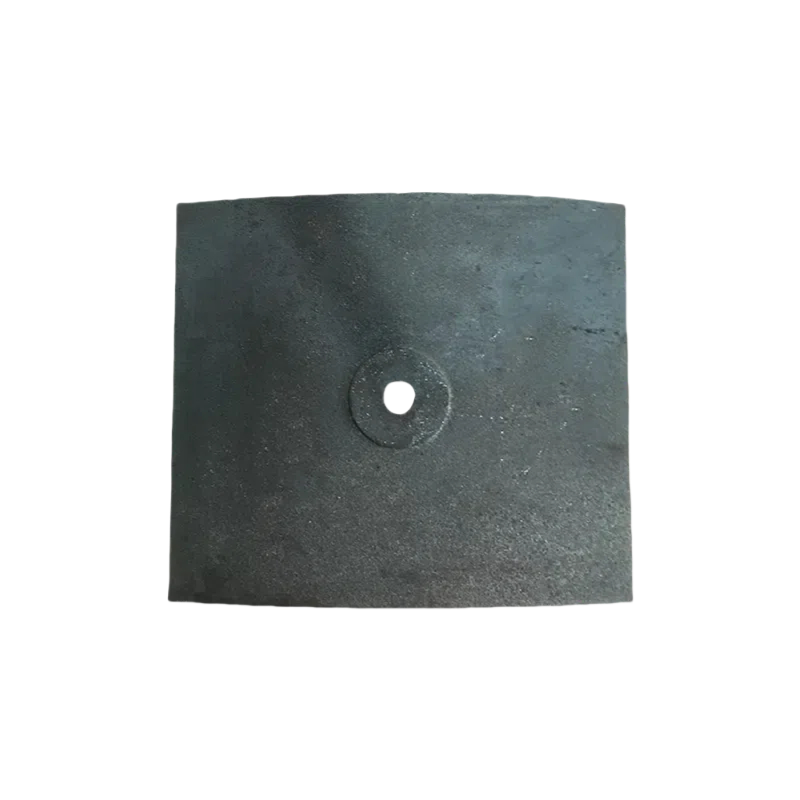

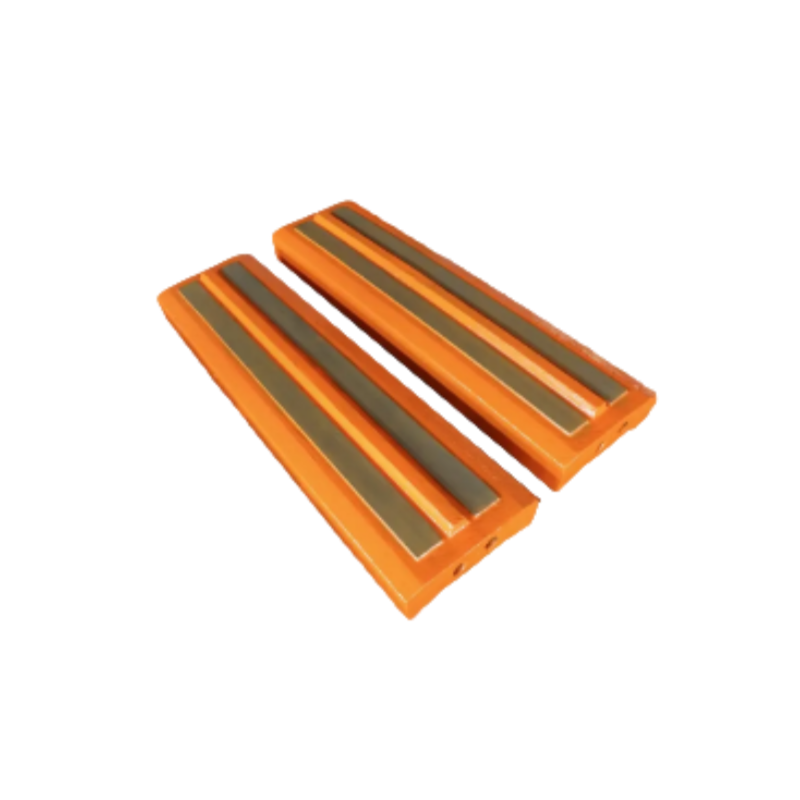

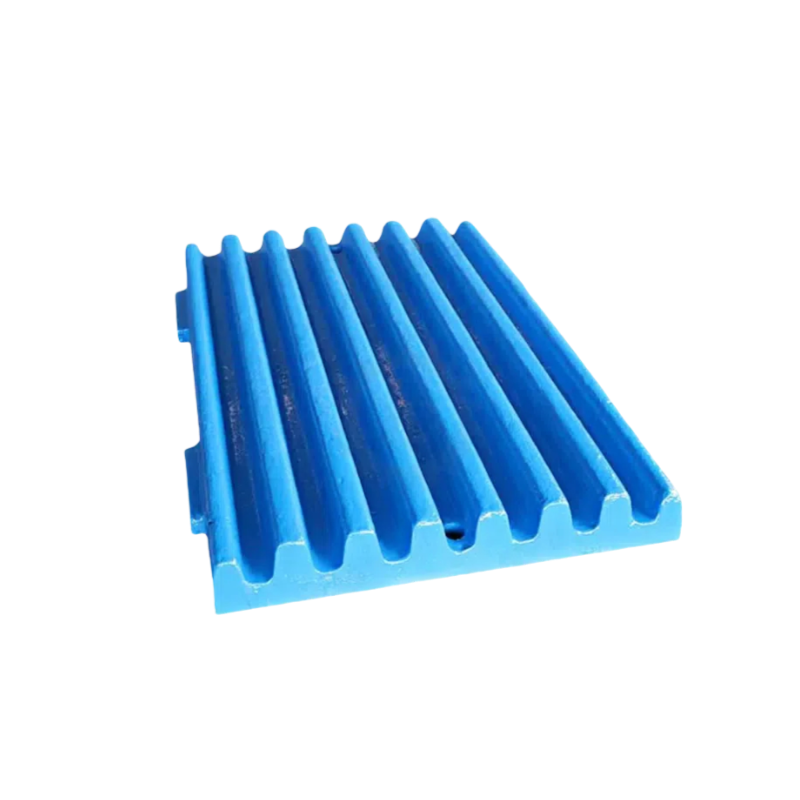

Wear-resistant Lining Plate

-

Impact Resistant Lining plate For Concrete Mixing Plant

-

High Hardness Lining Plate For Concrete Mixing Plant

-

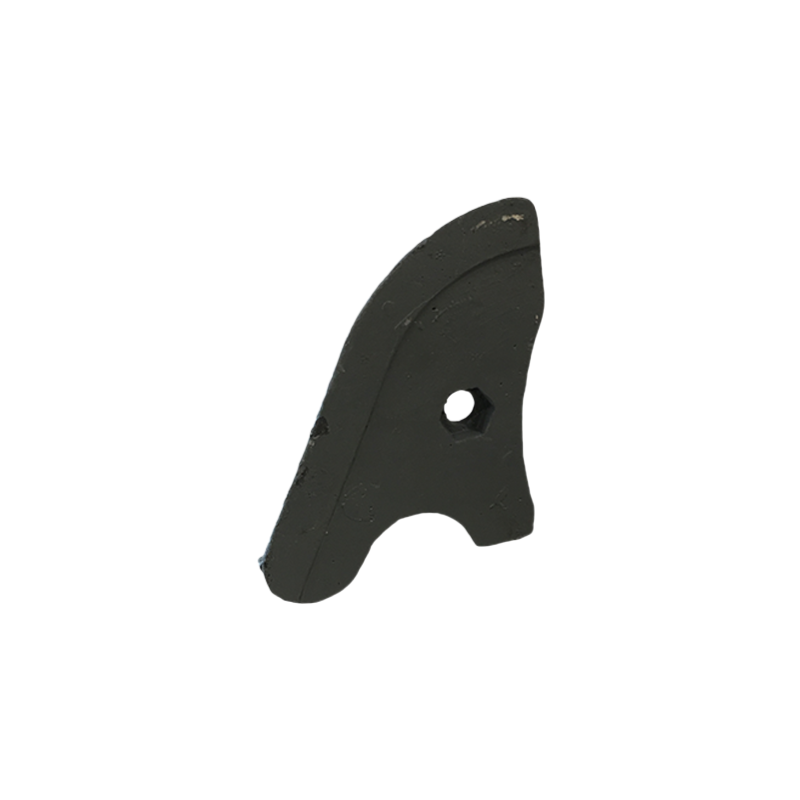

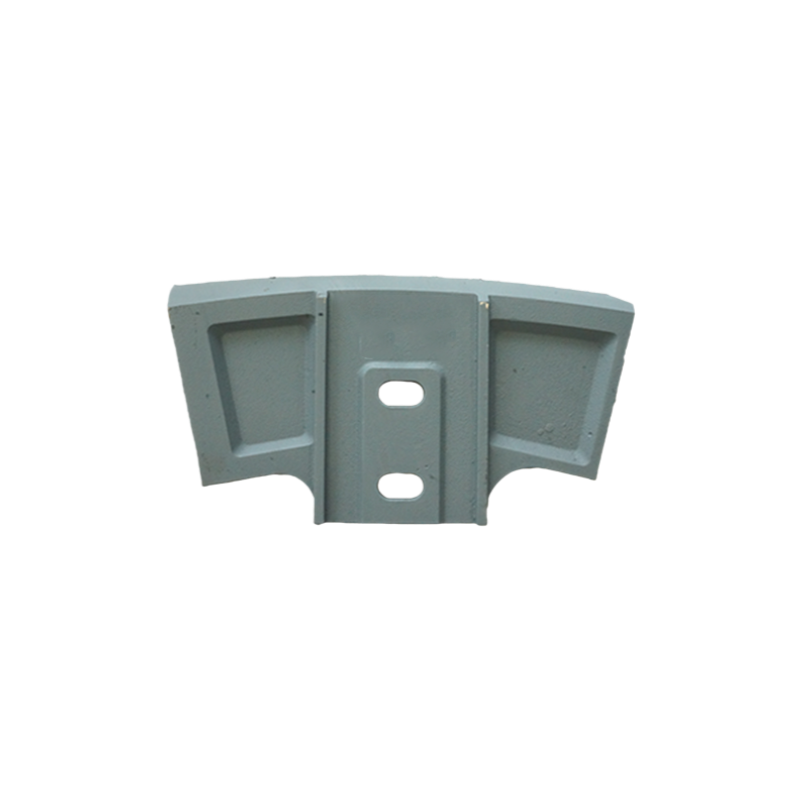

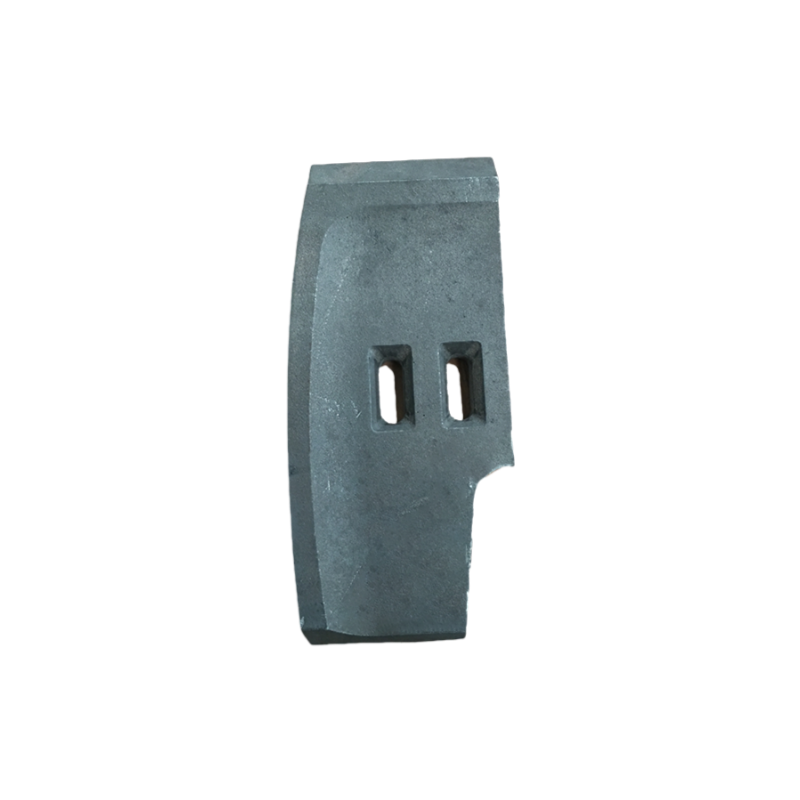

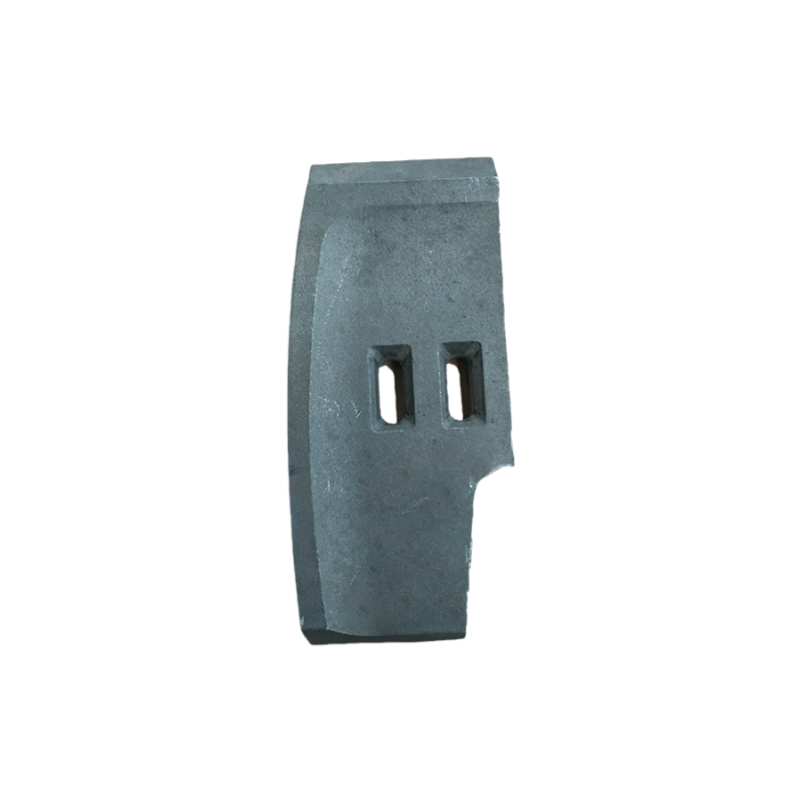

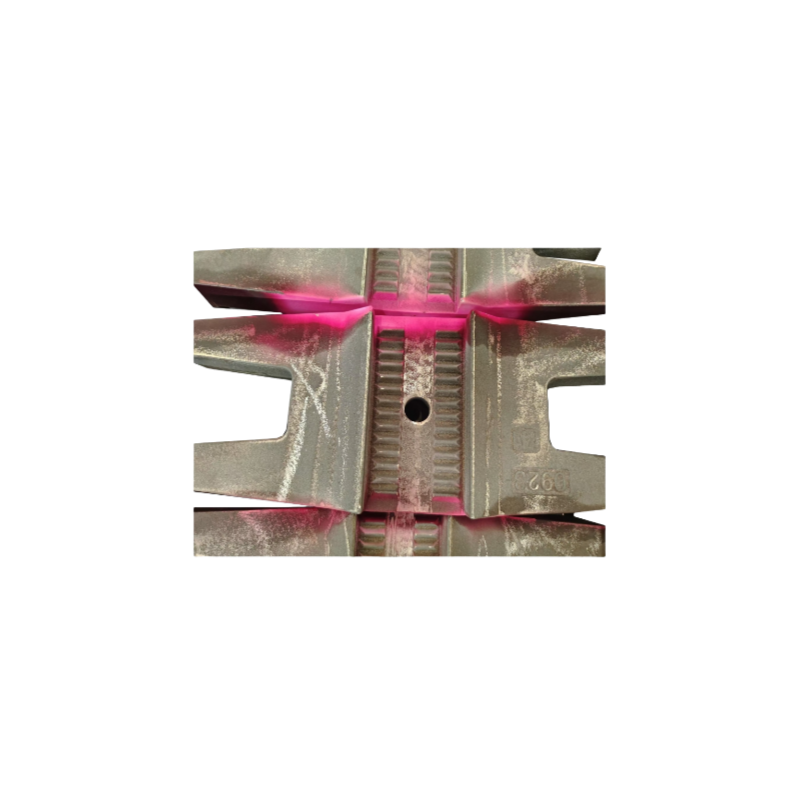

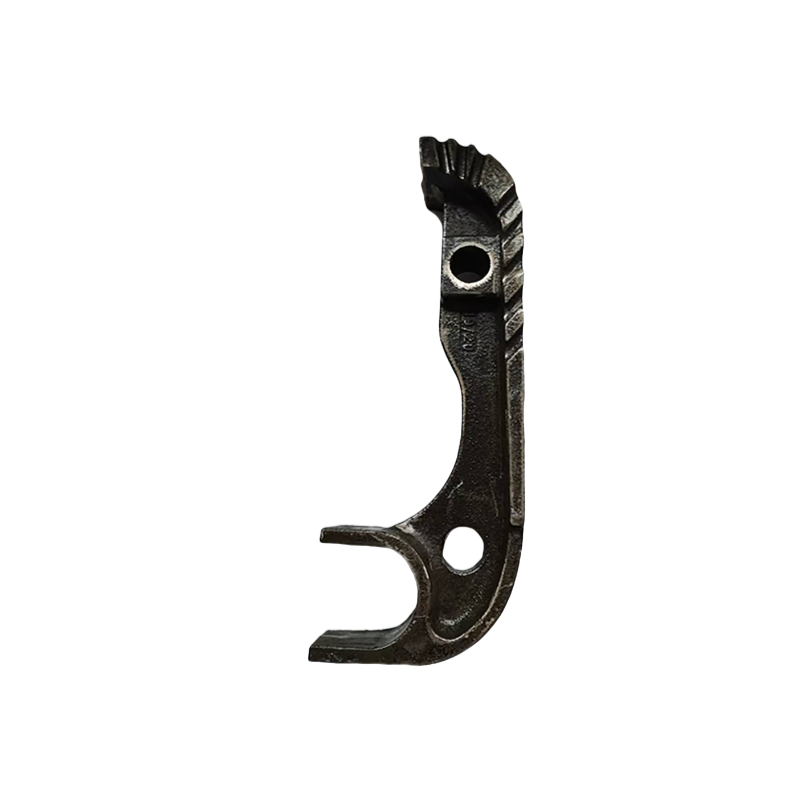

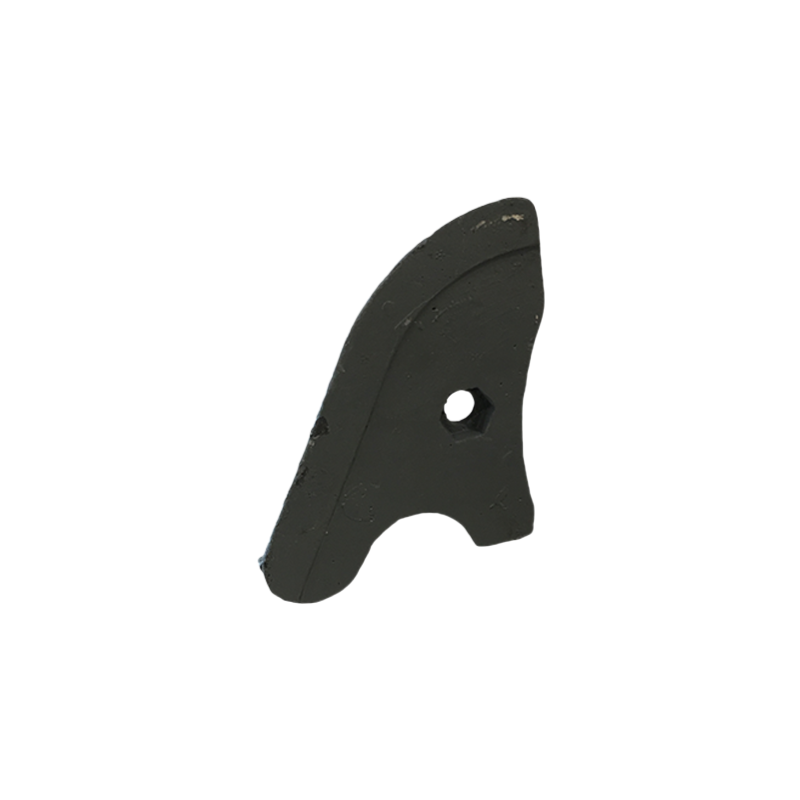

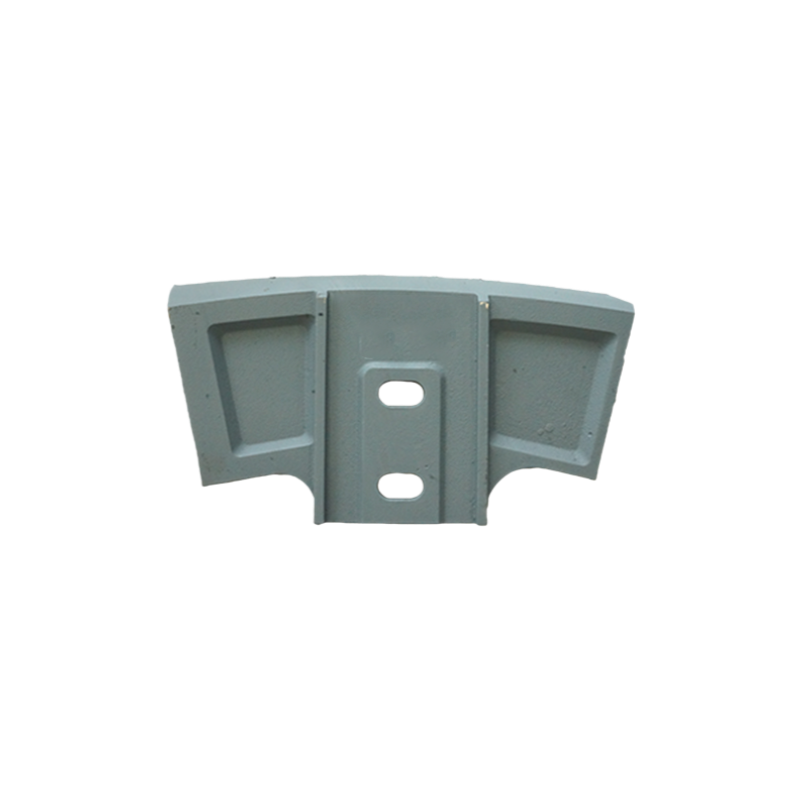

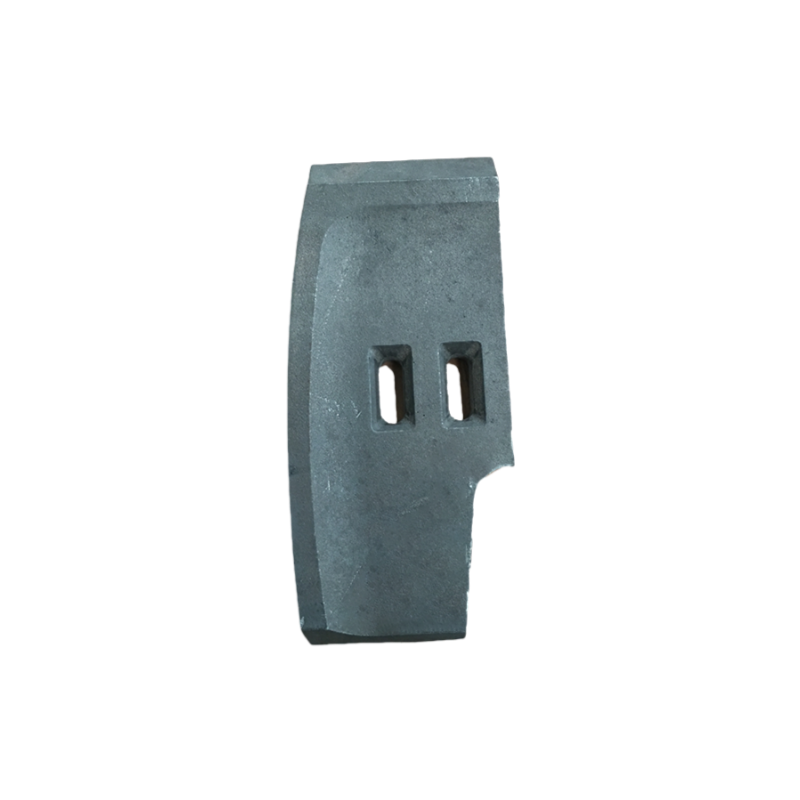

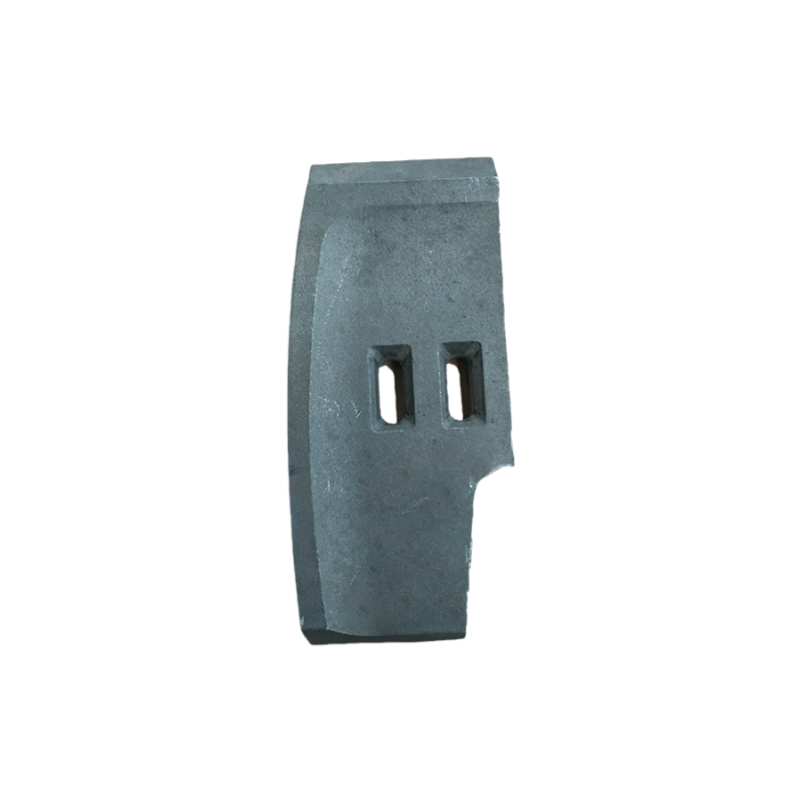

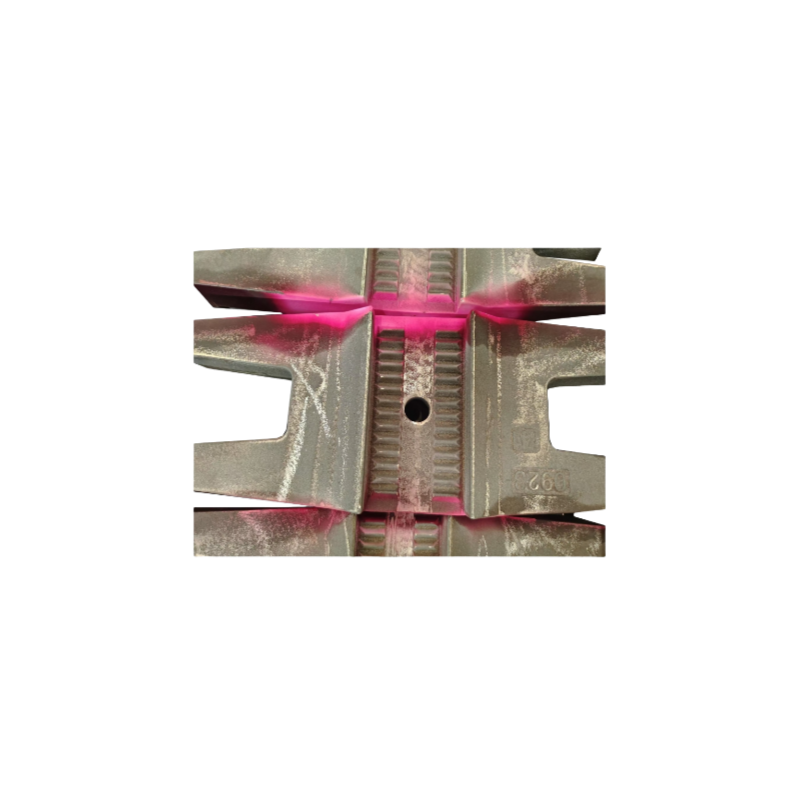

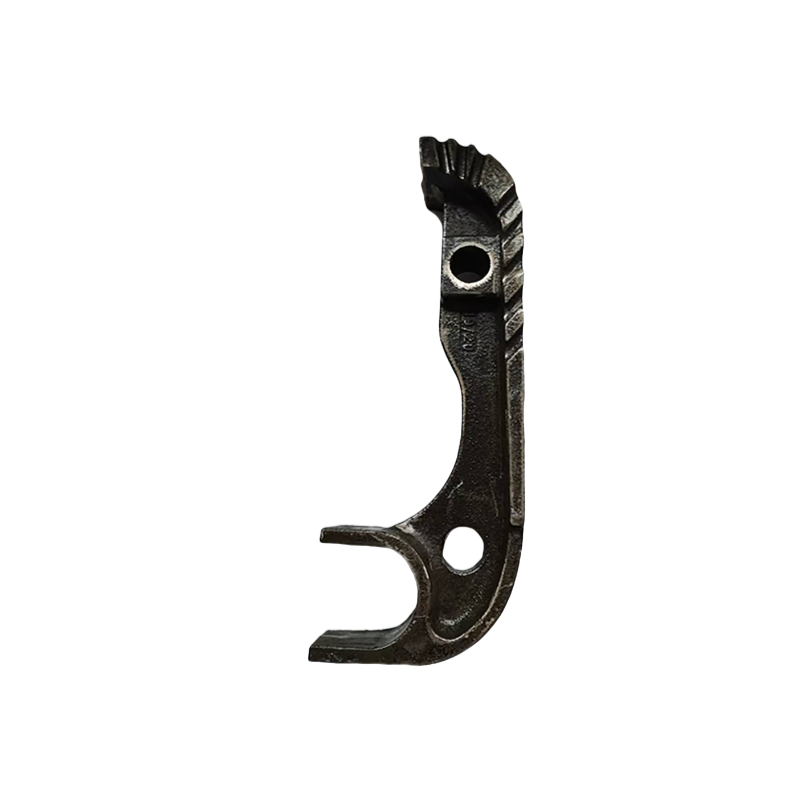

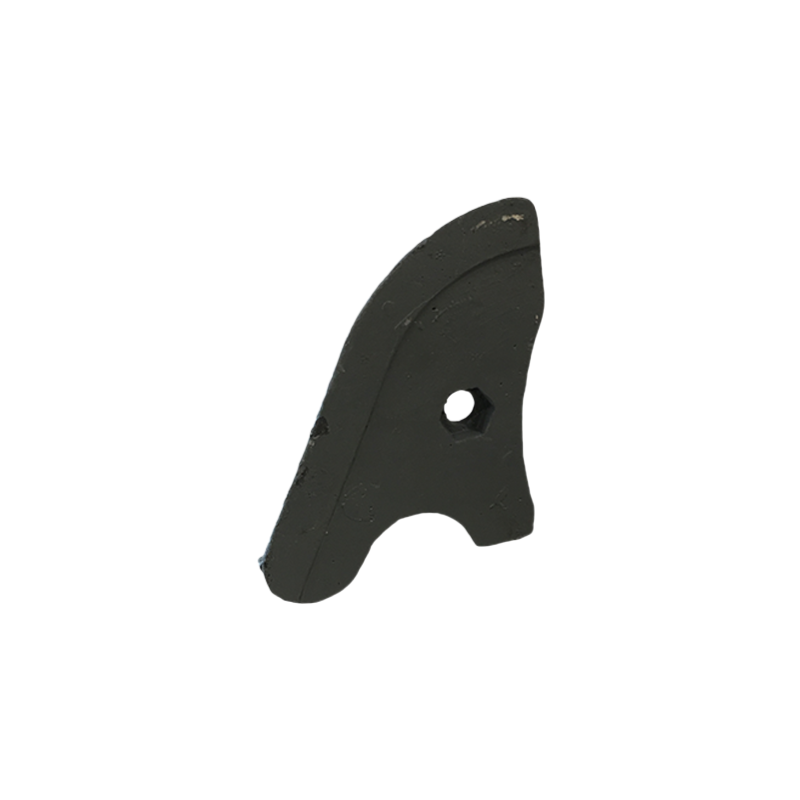

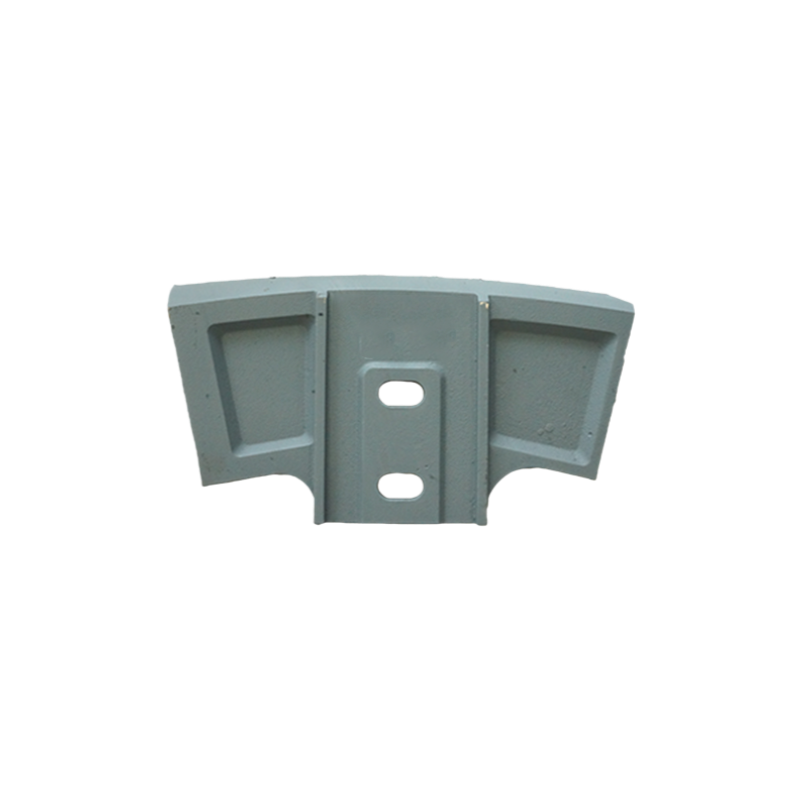

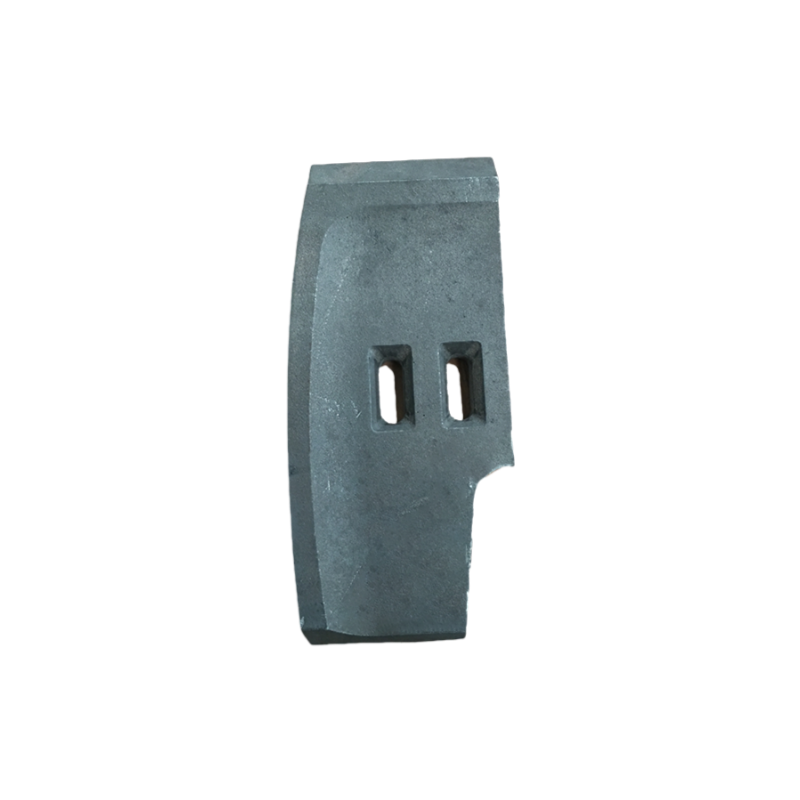

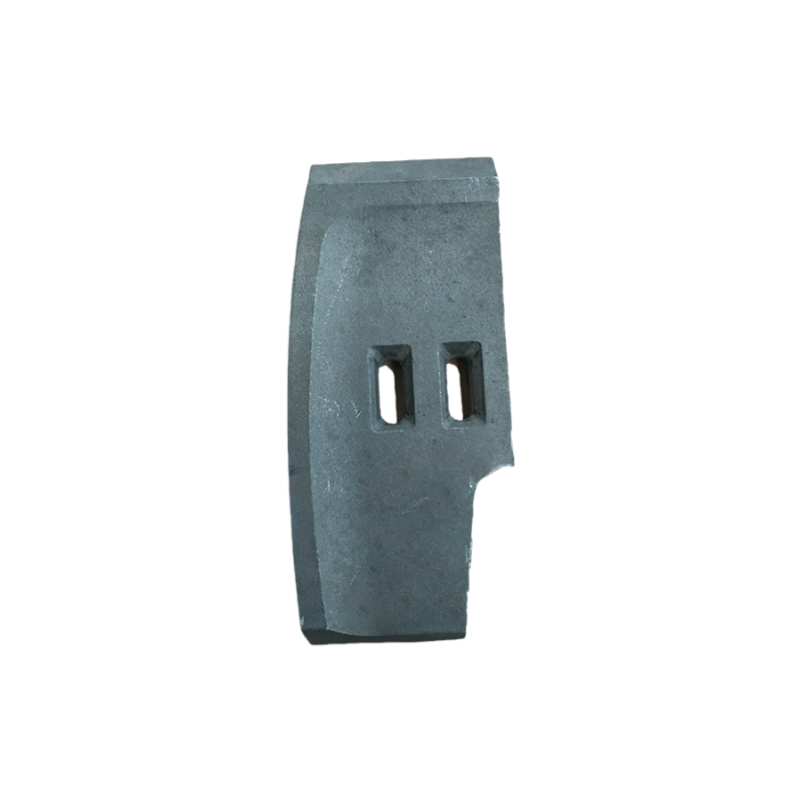

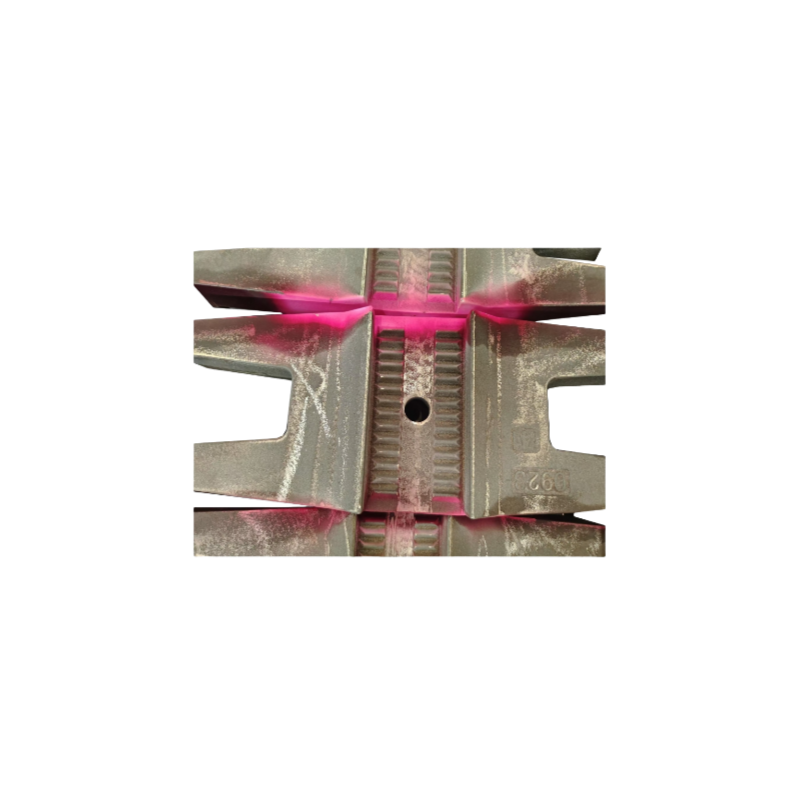

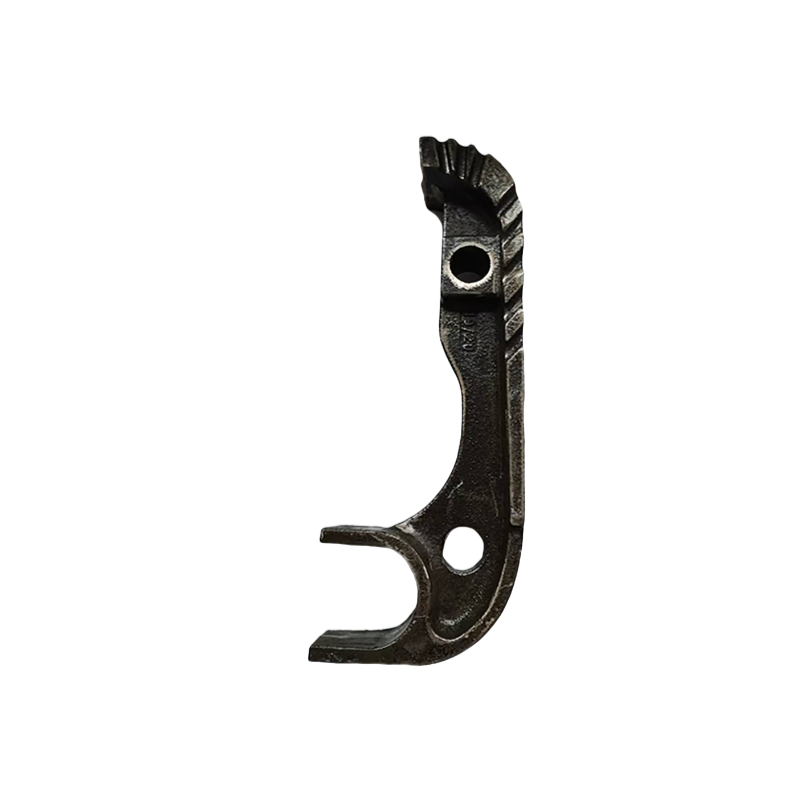

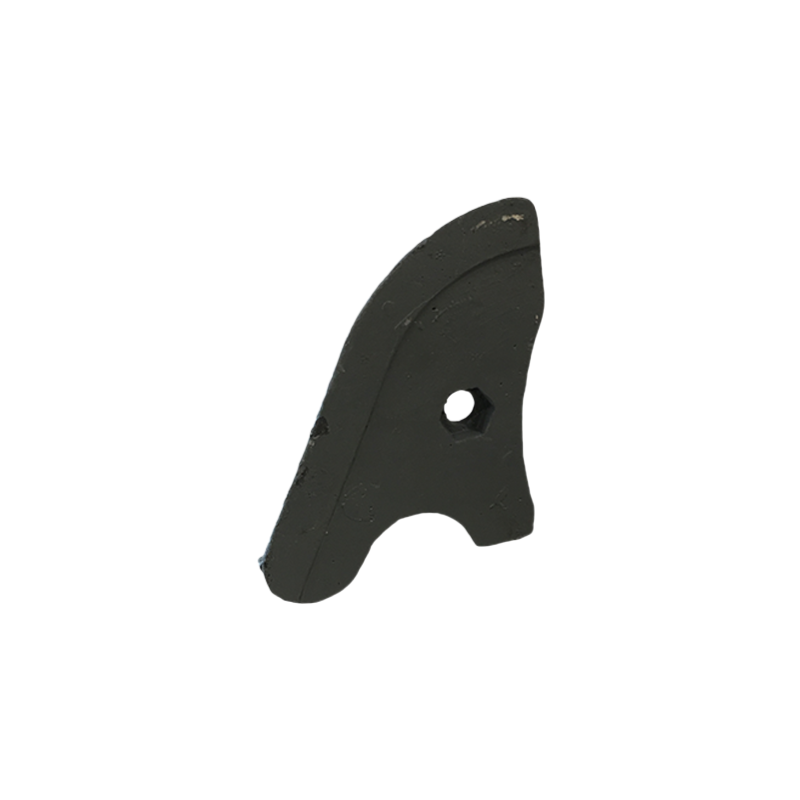

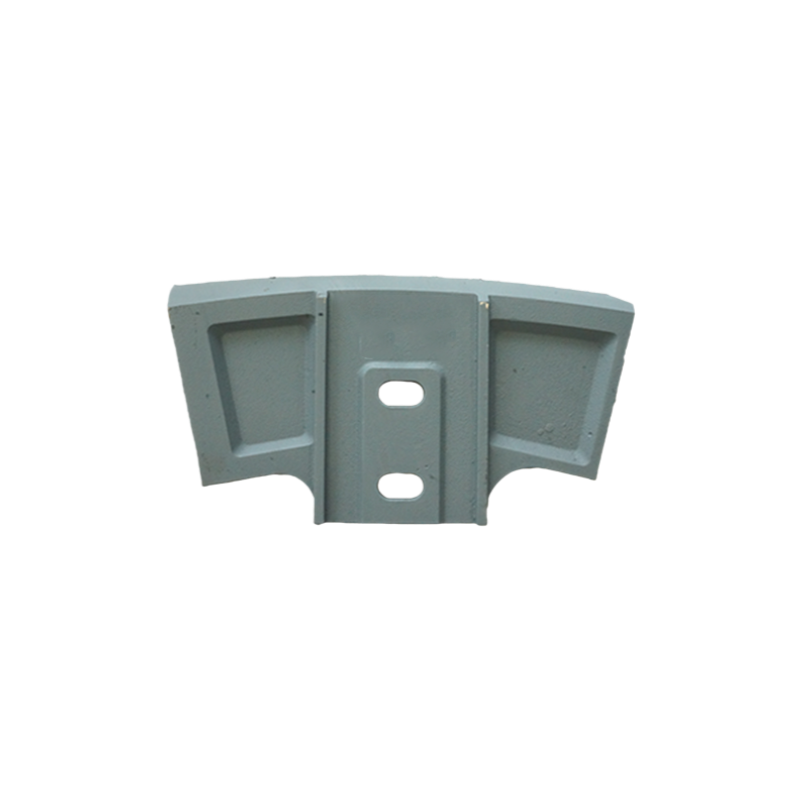

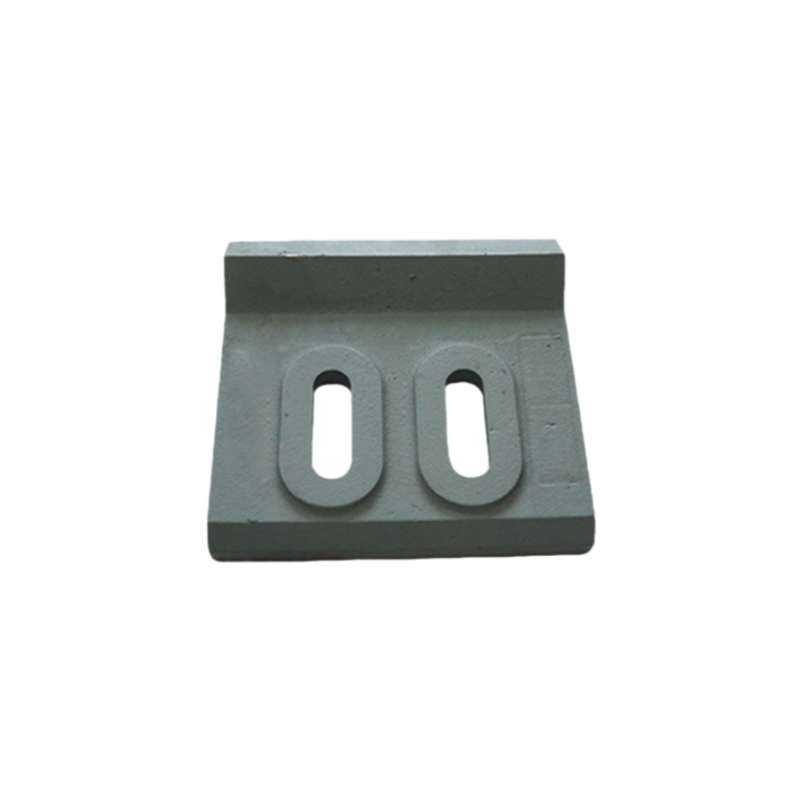

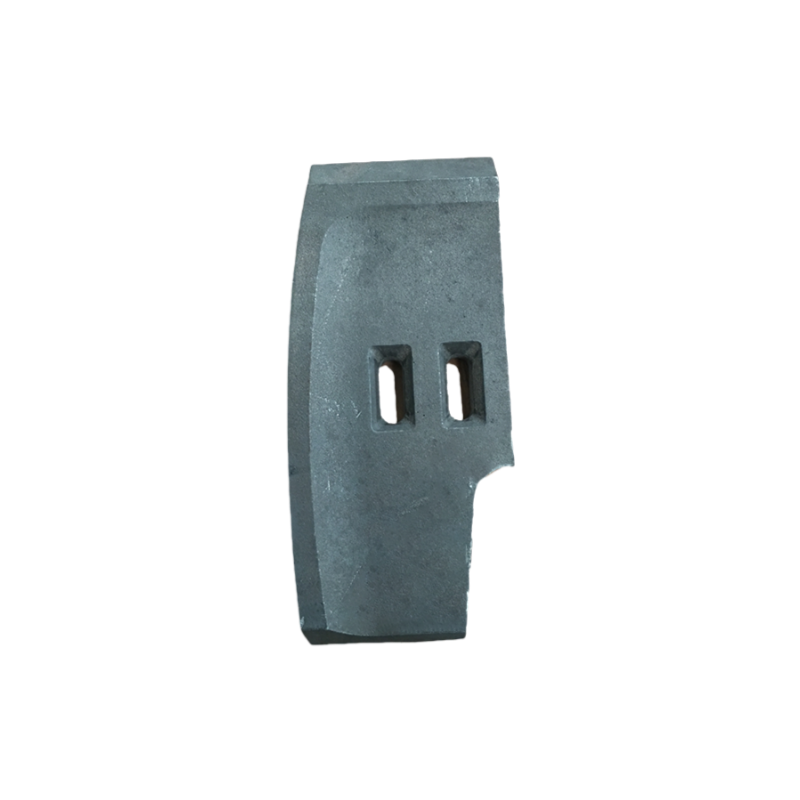

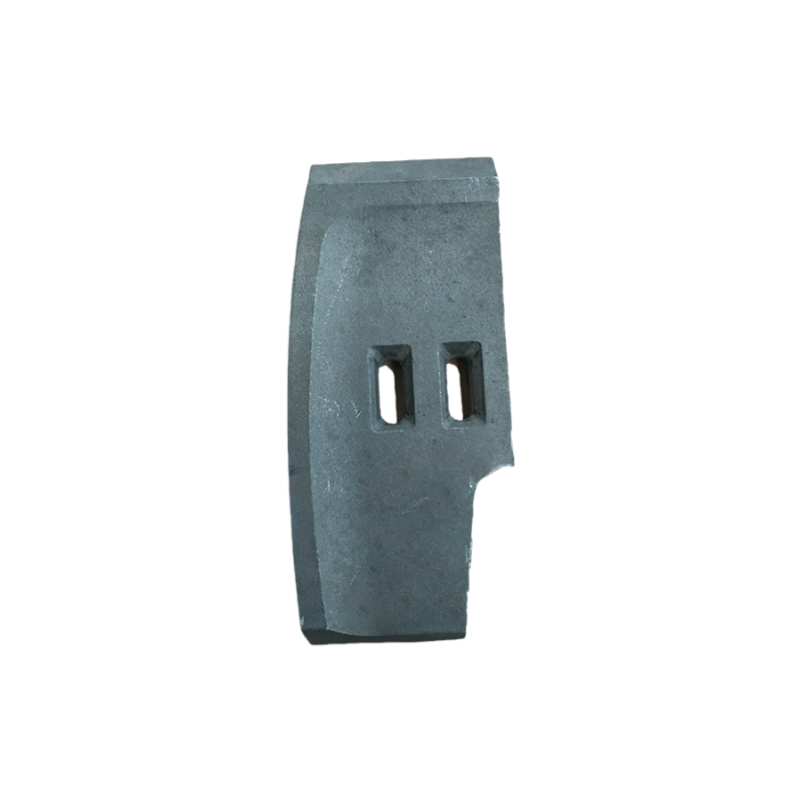

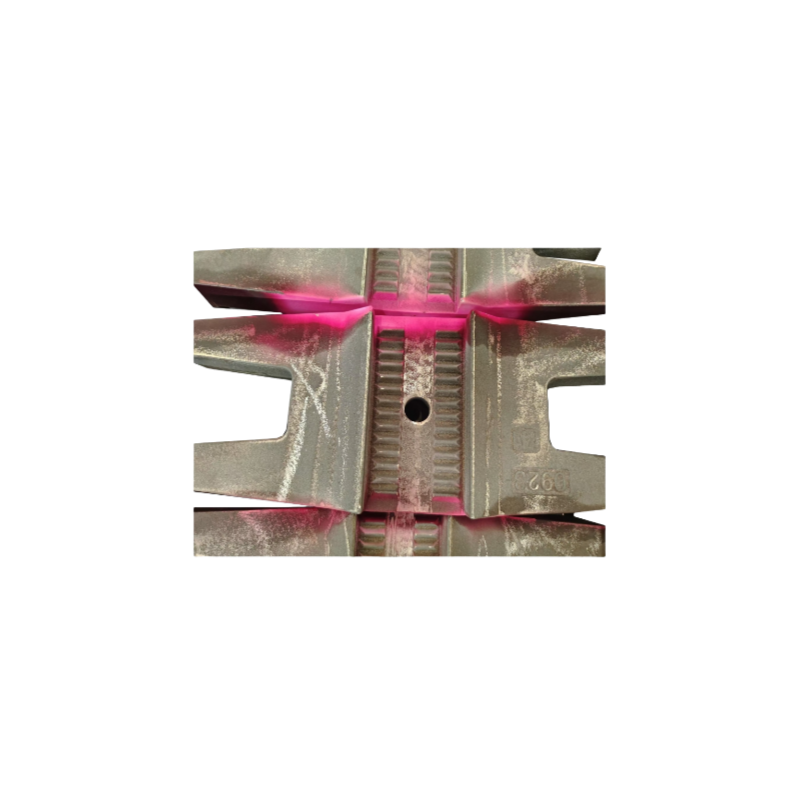

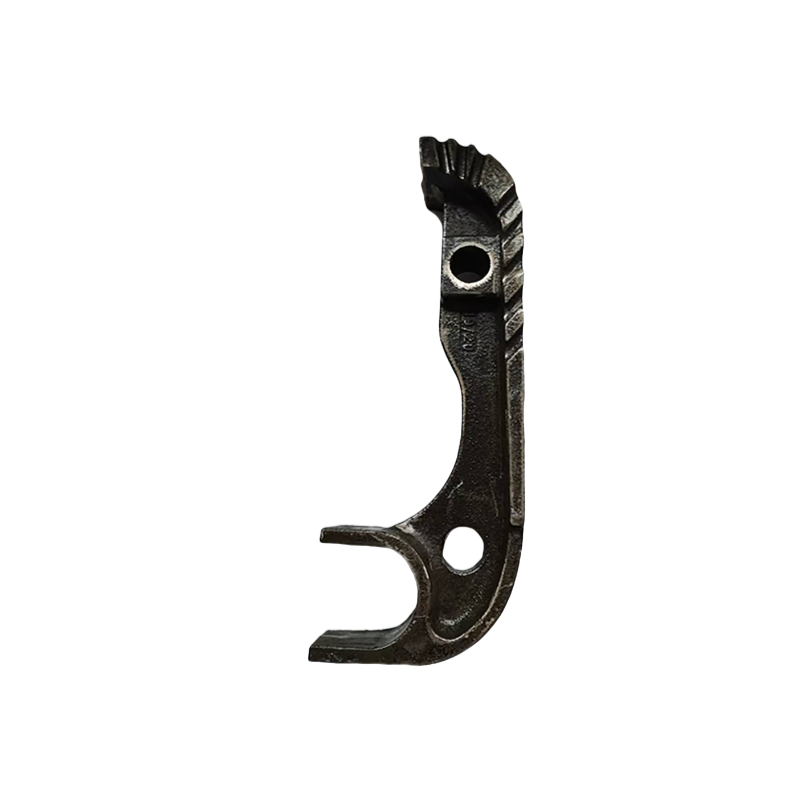

Mixing Arm For Concrete Mixing Plant

-

Arm Protection-Concrete Mixing Plant

-

Mixing Arm-Concrete Mixing Plant

-

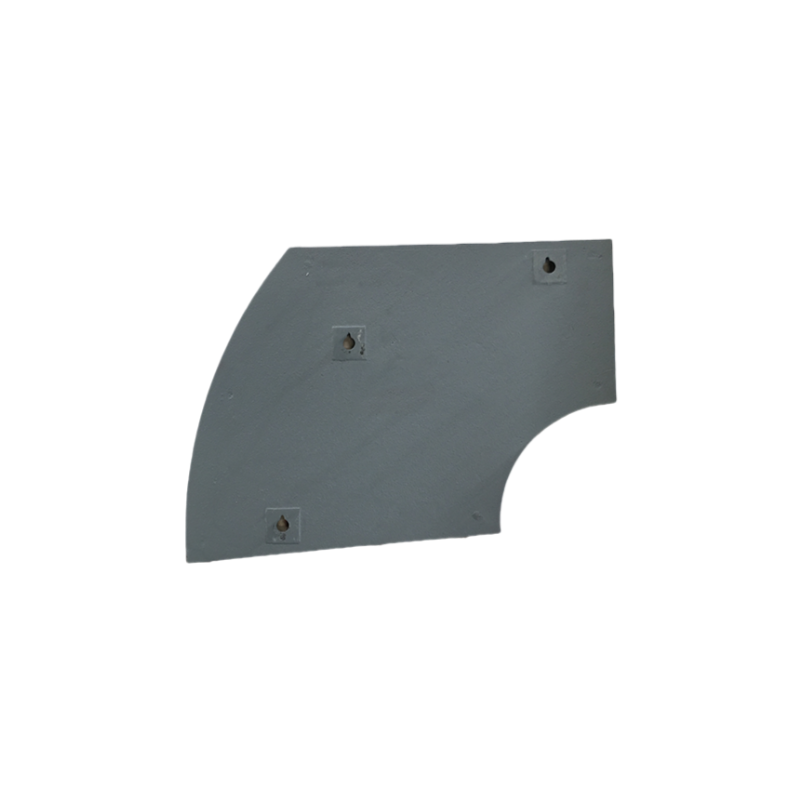

Concrete Mixing Plant Wear-resistant Lining Plate

-

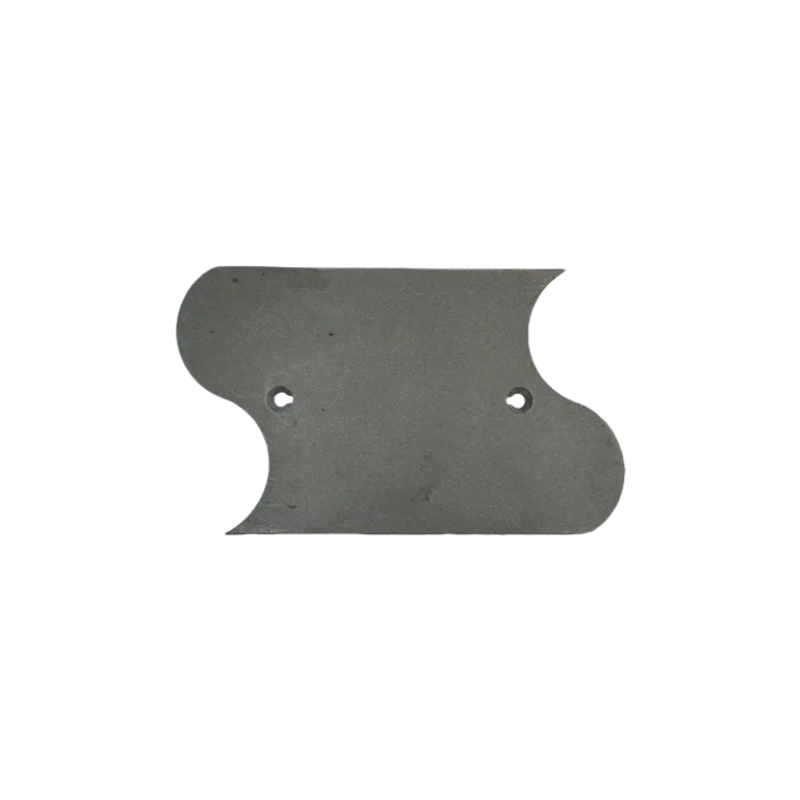

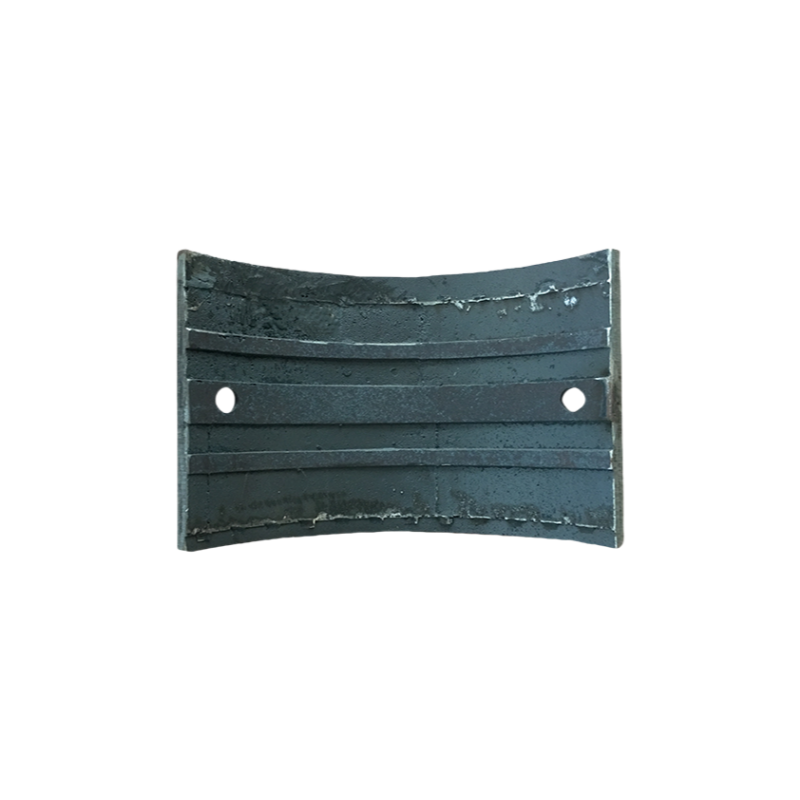

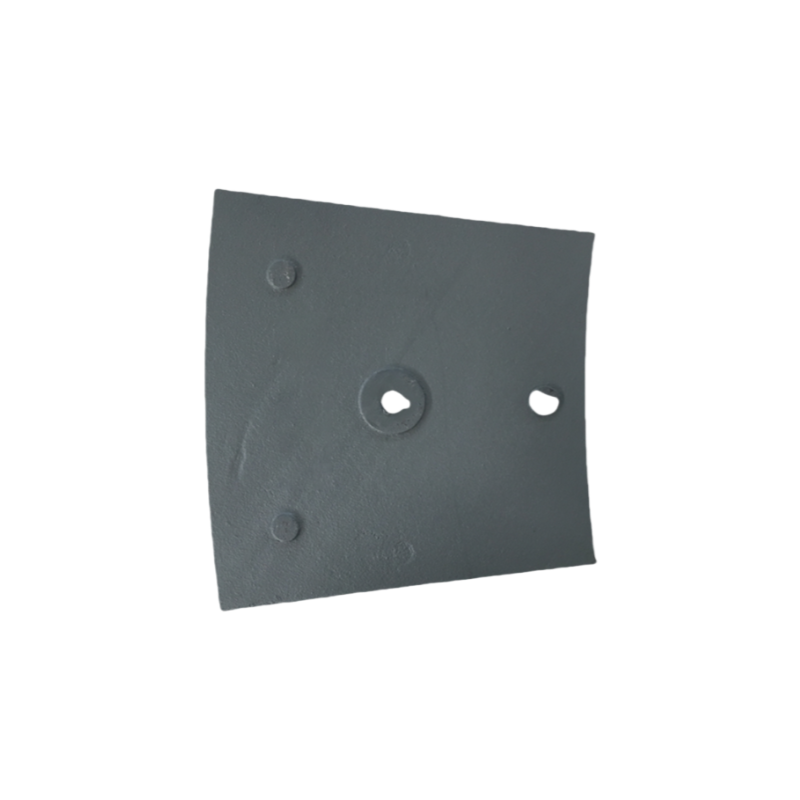

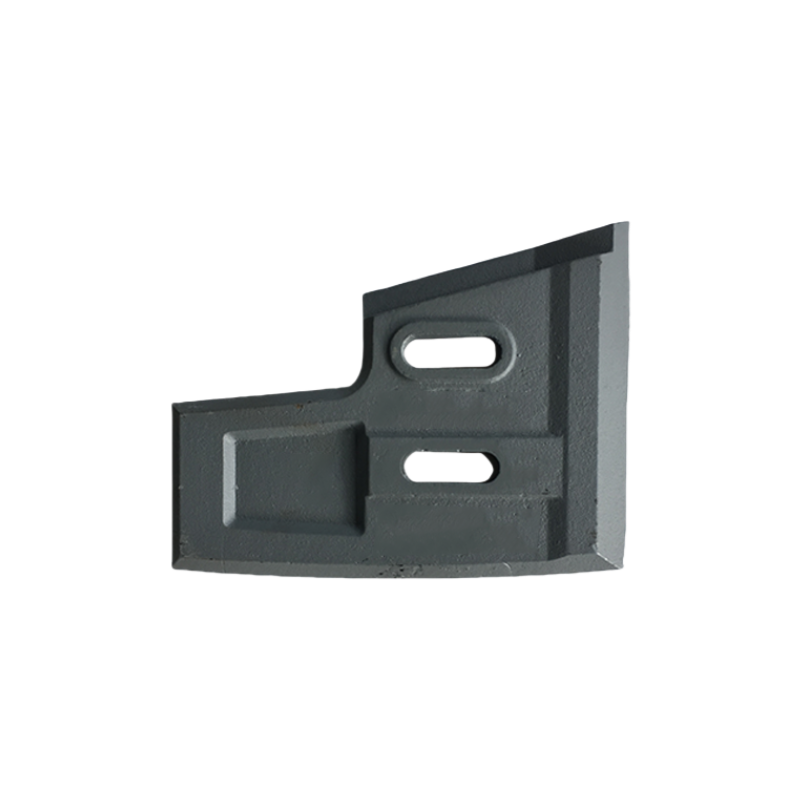

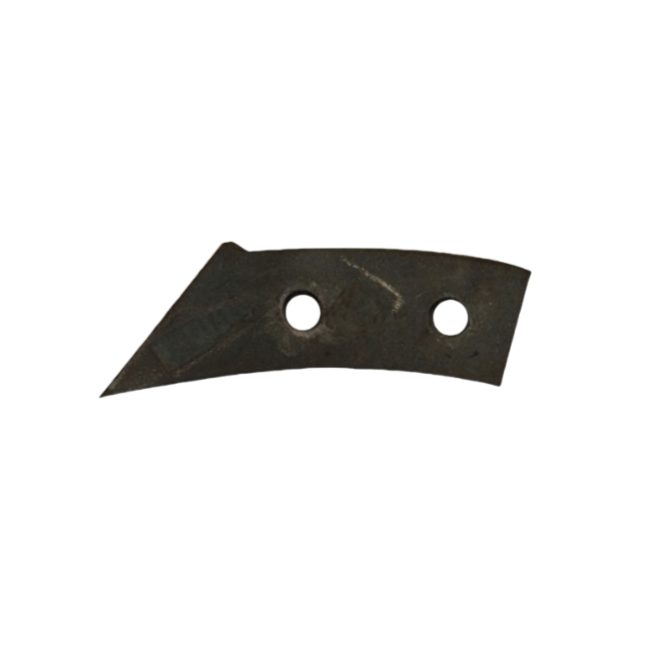

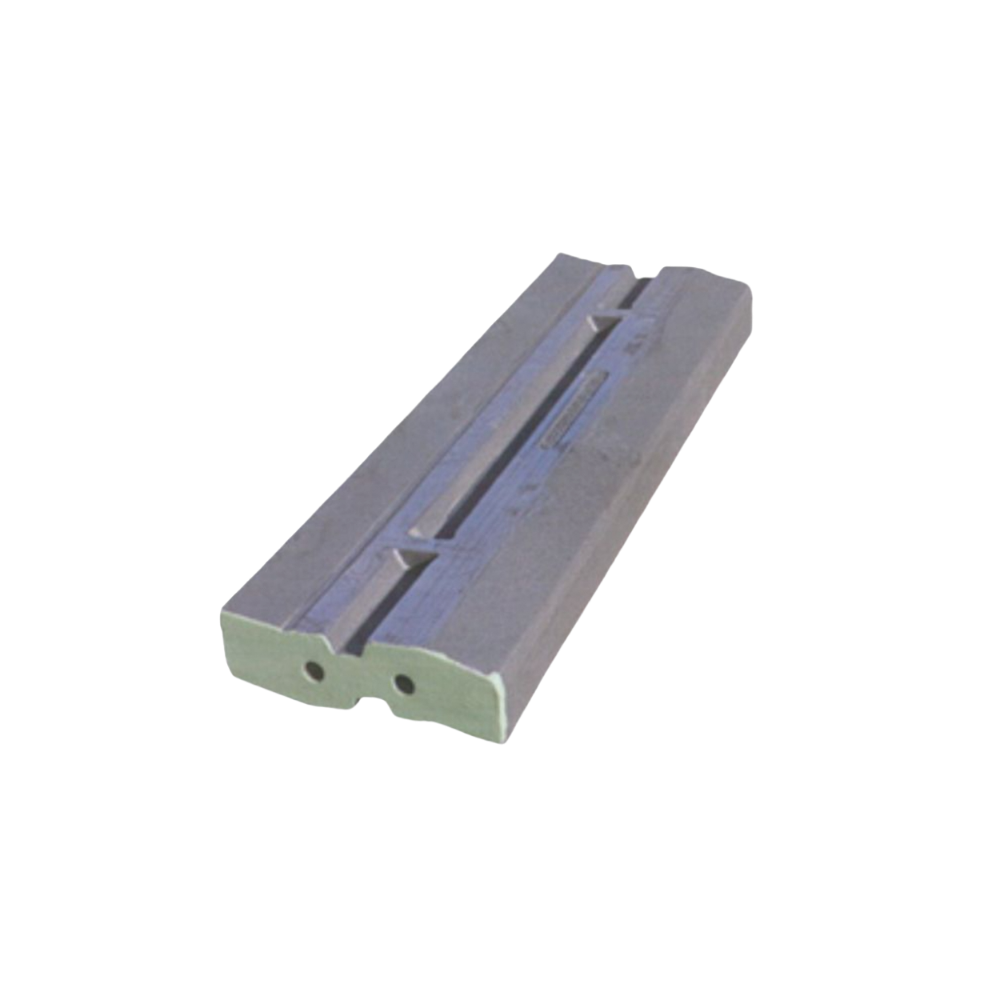

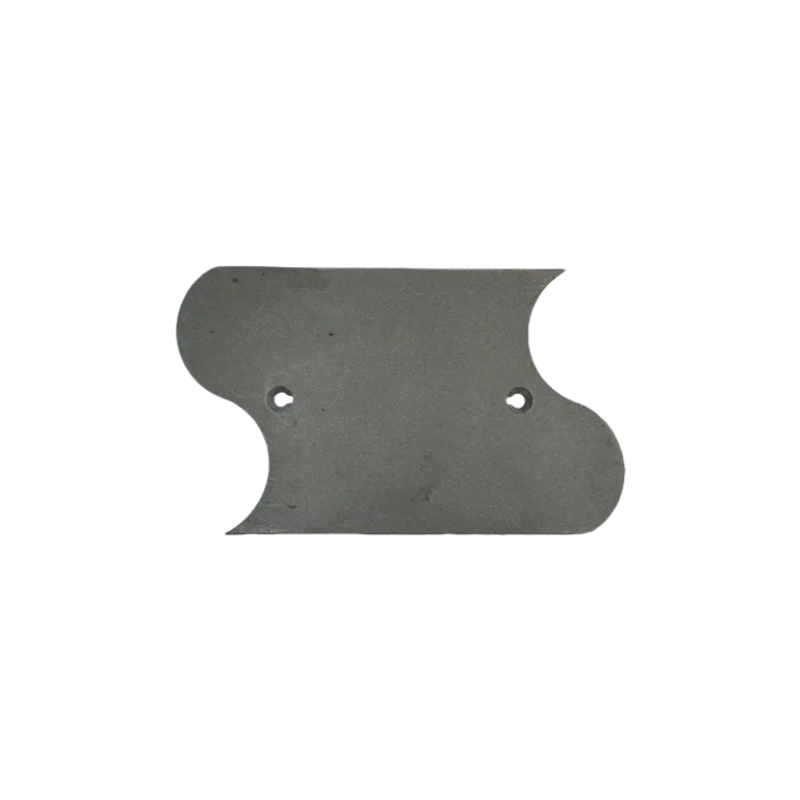

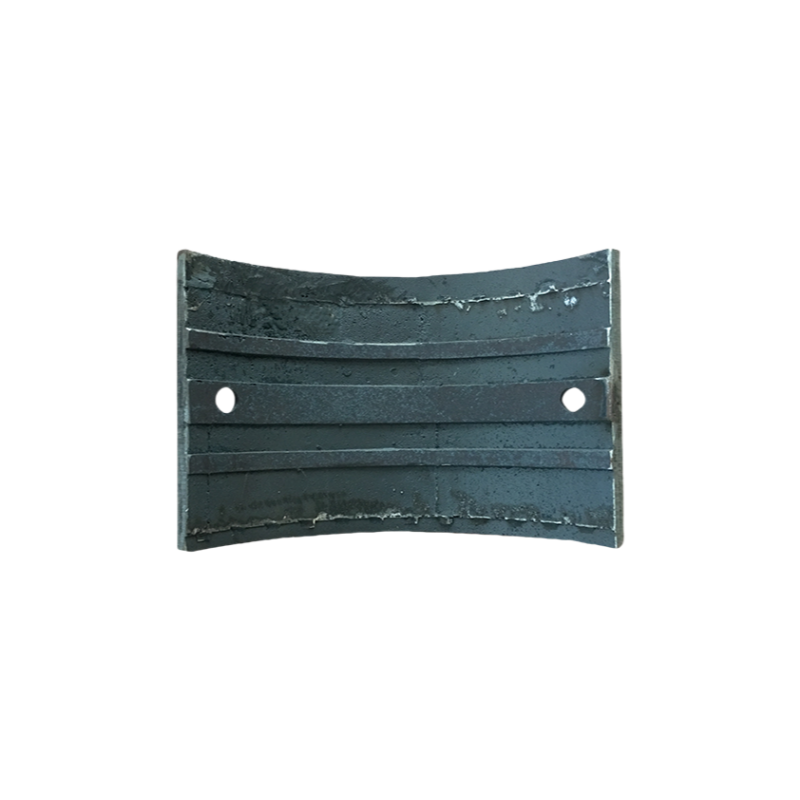

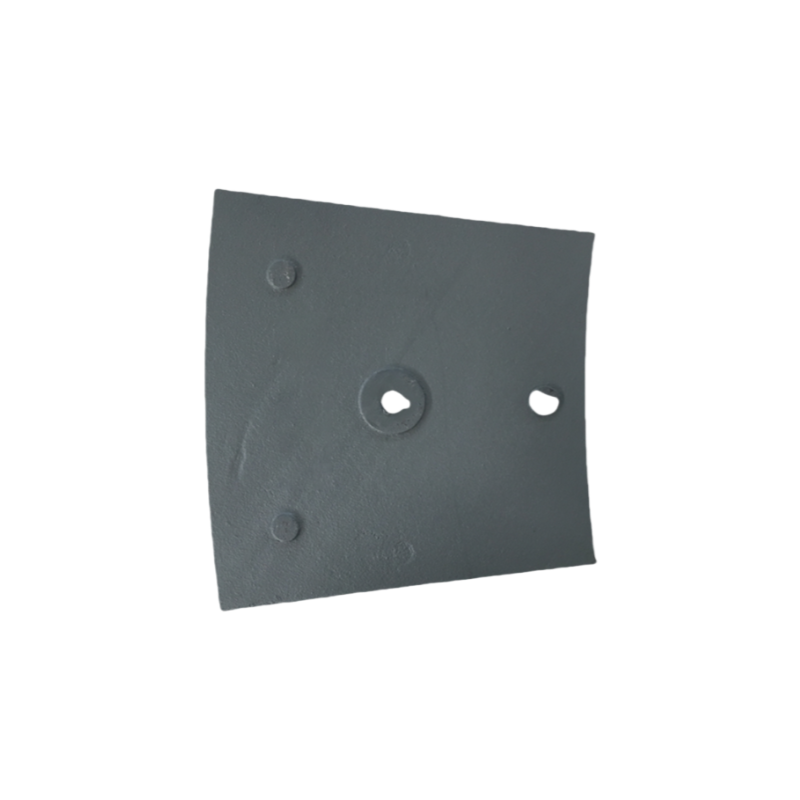

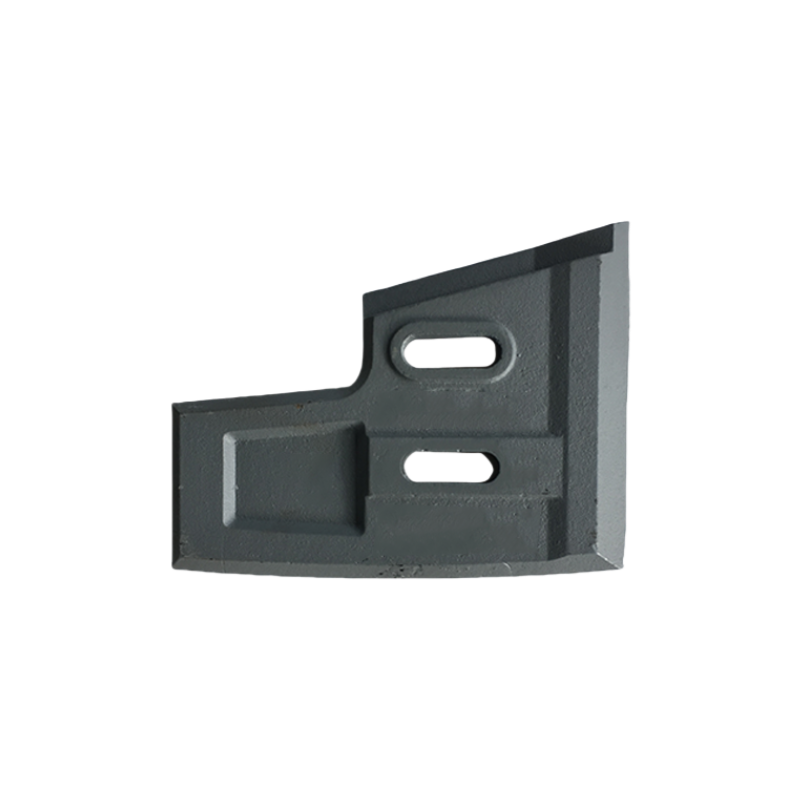

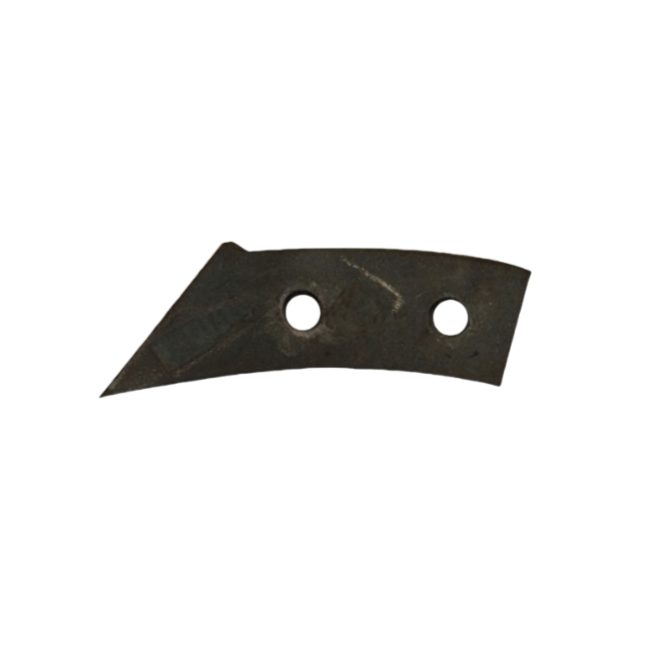

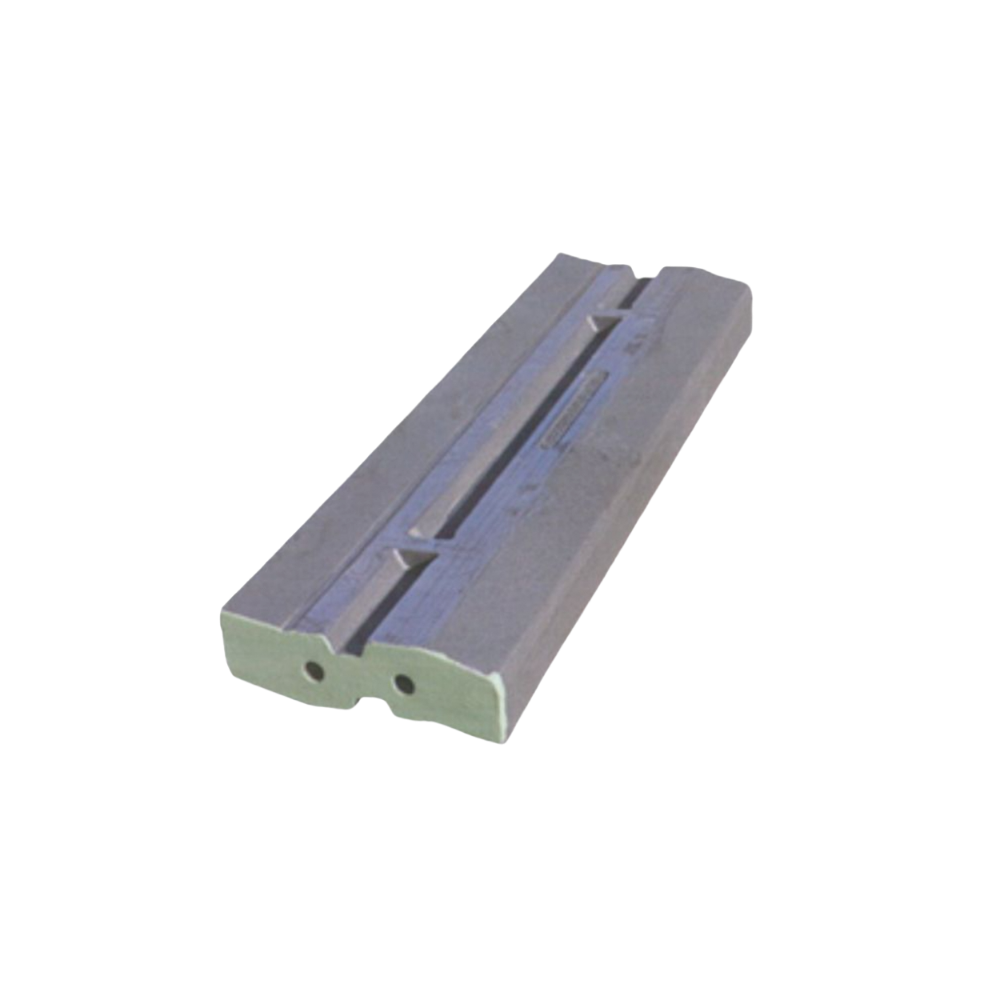

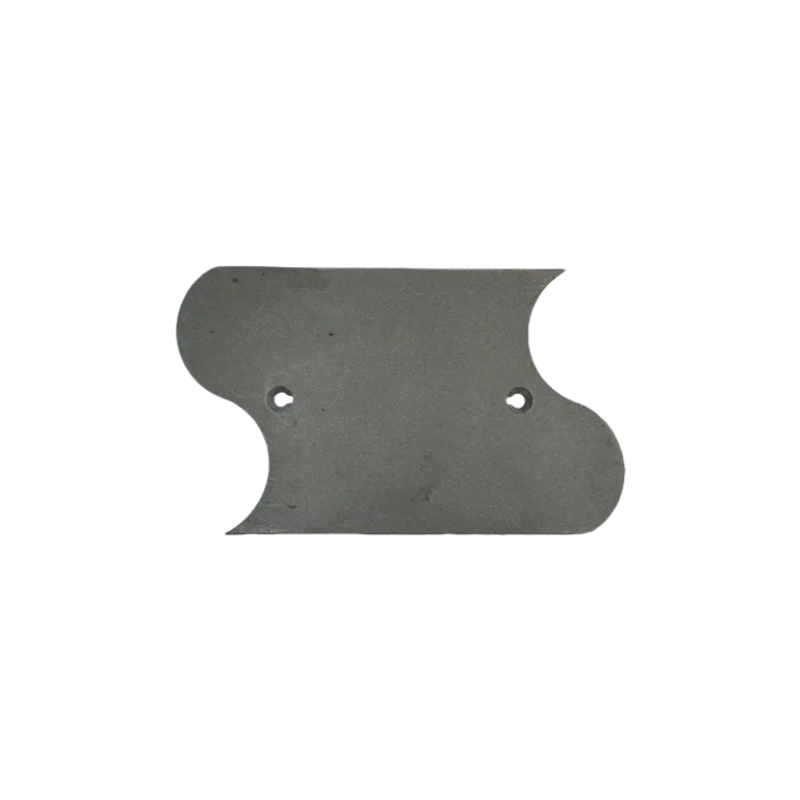

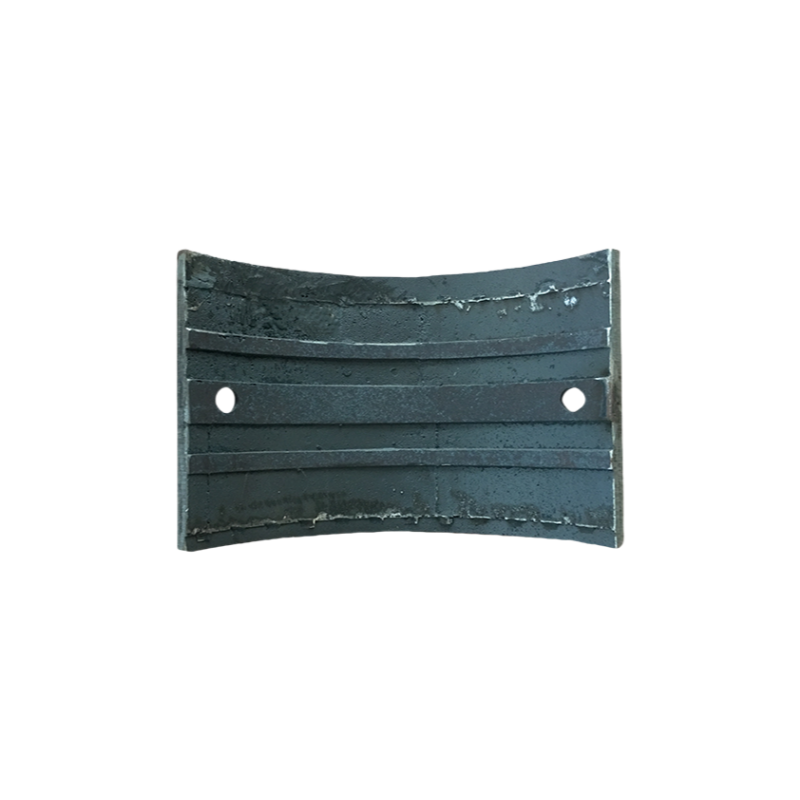

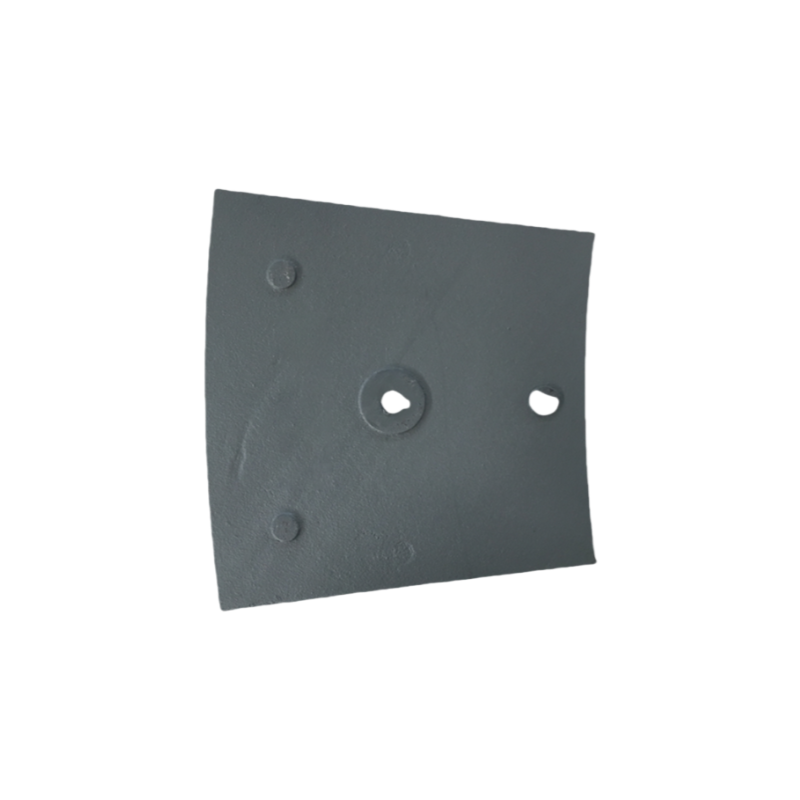

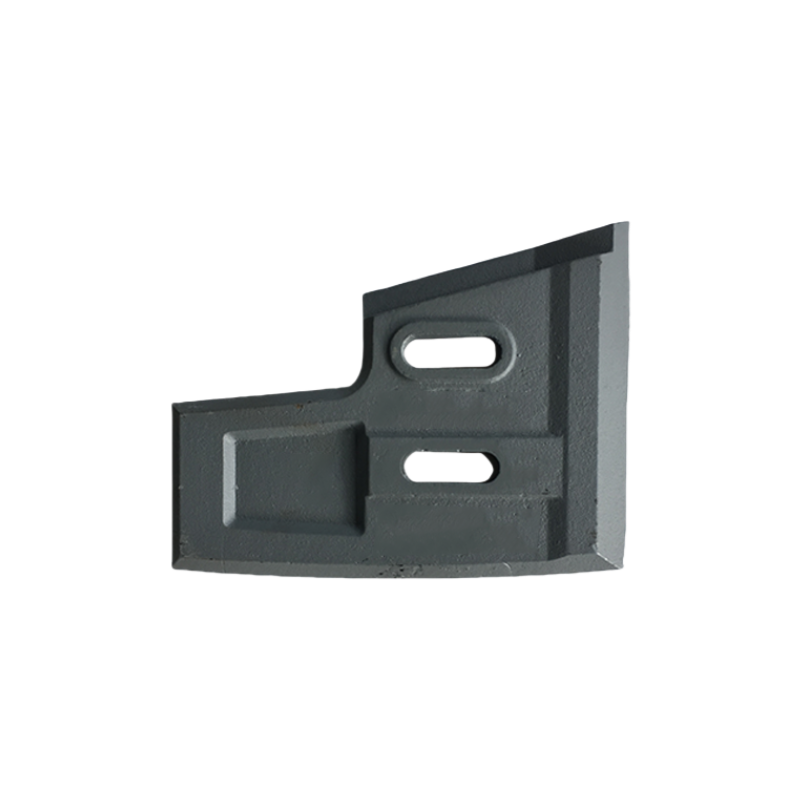

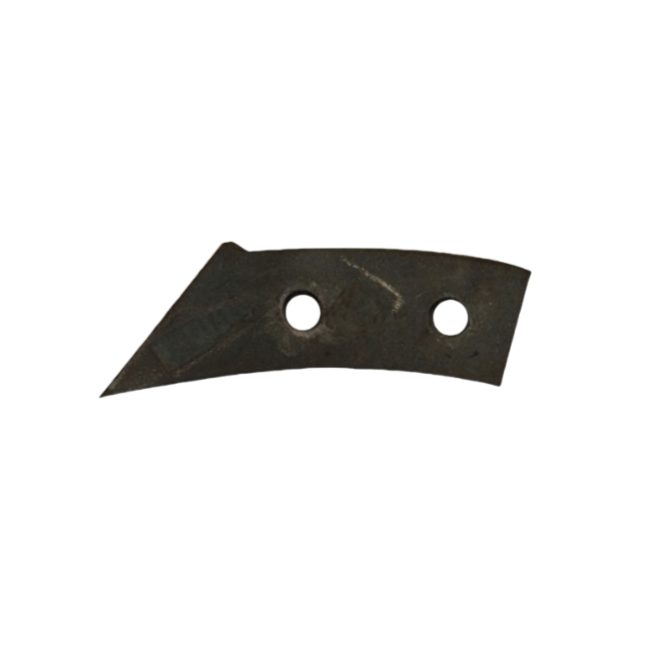

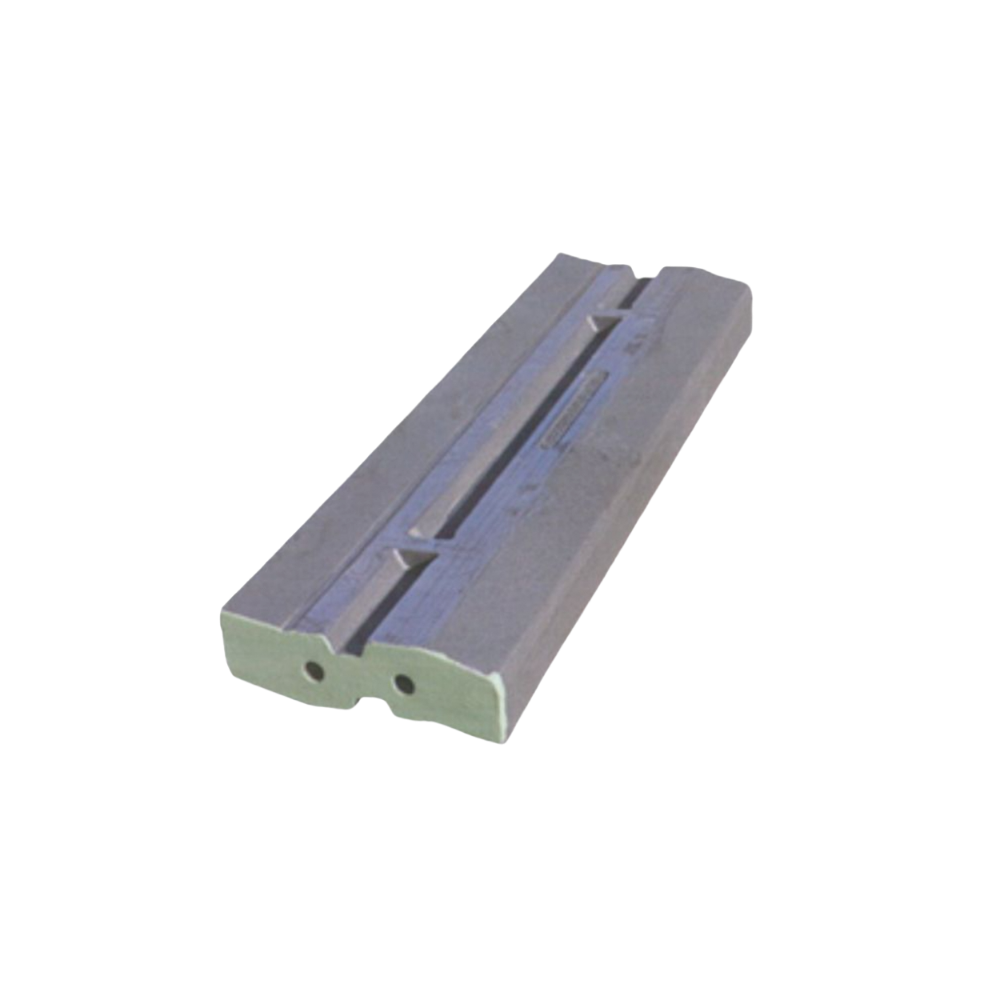

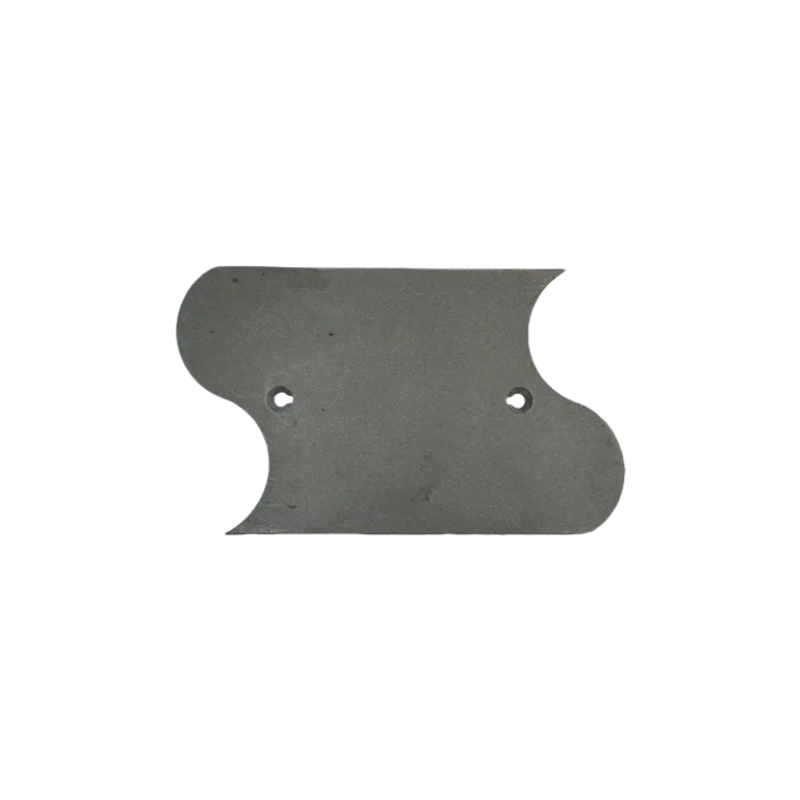

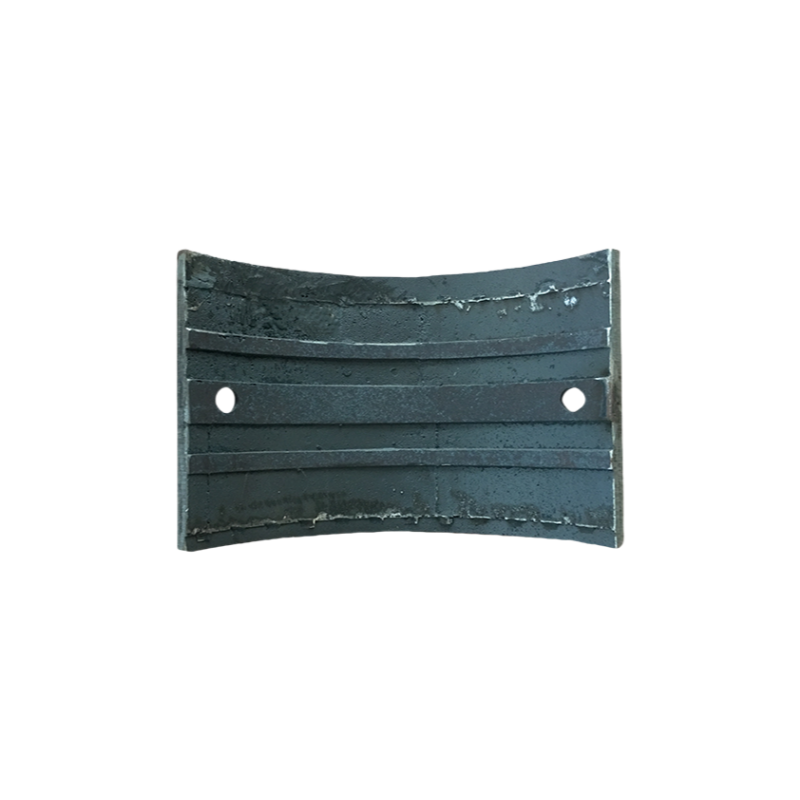

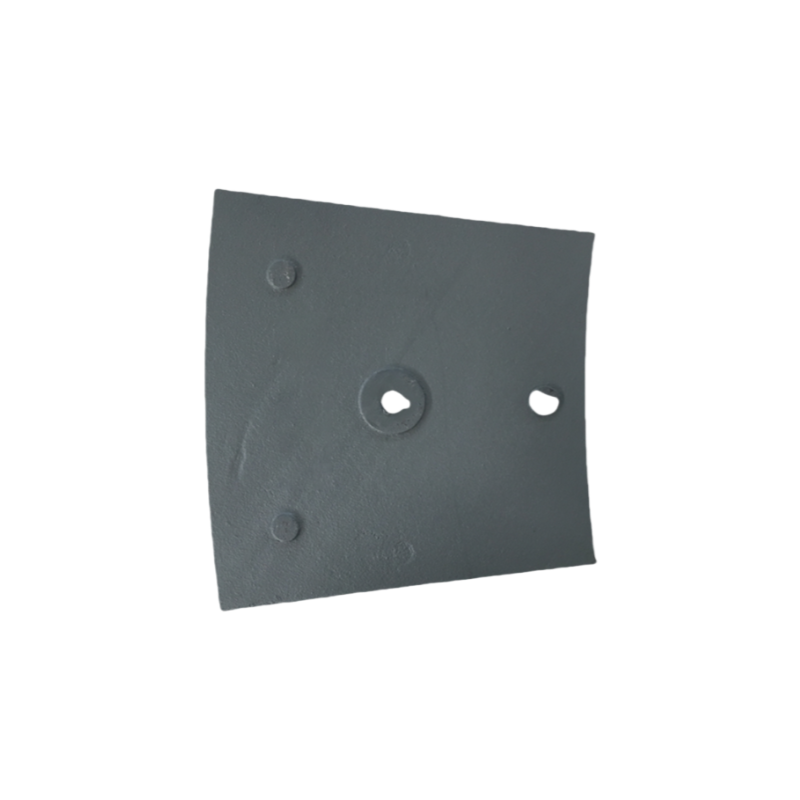

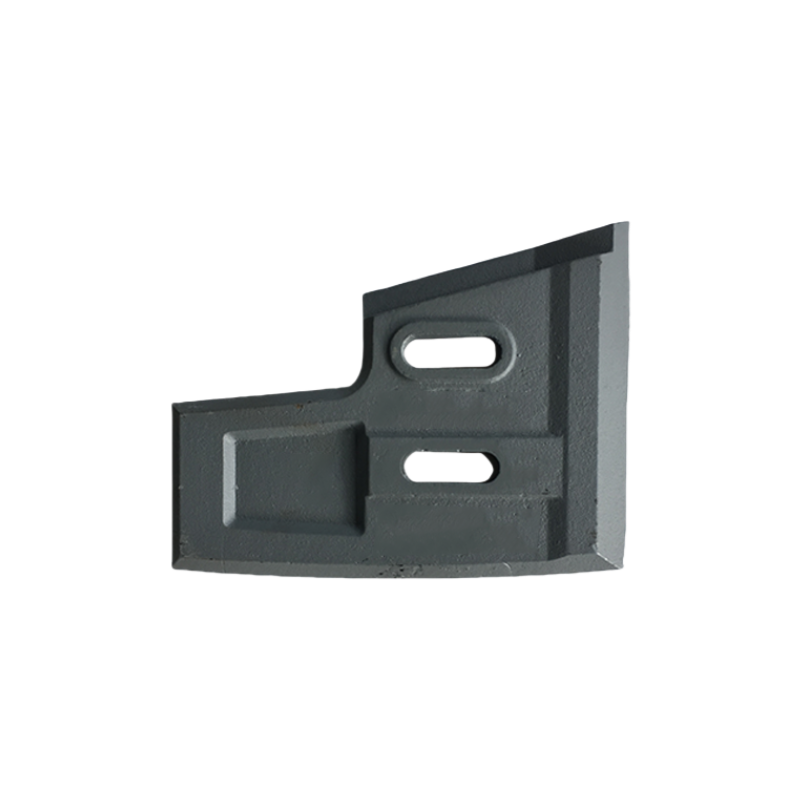

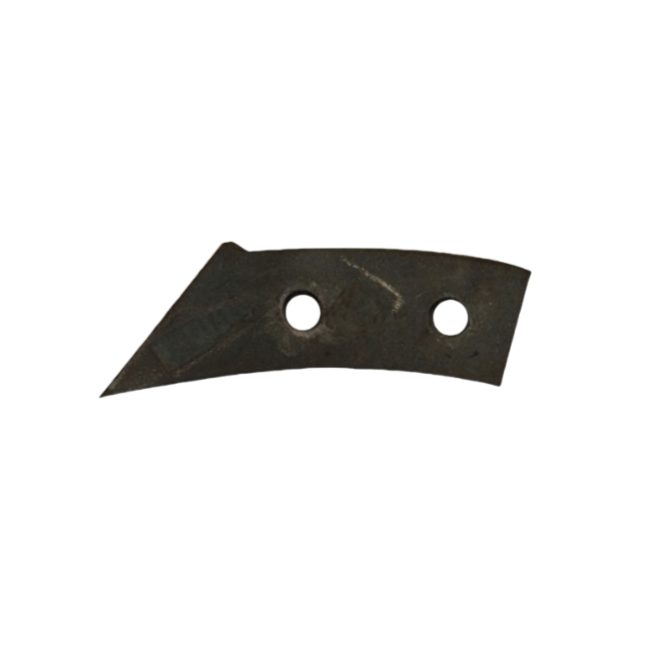

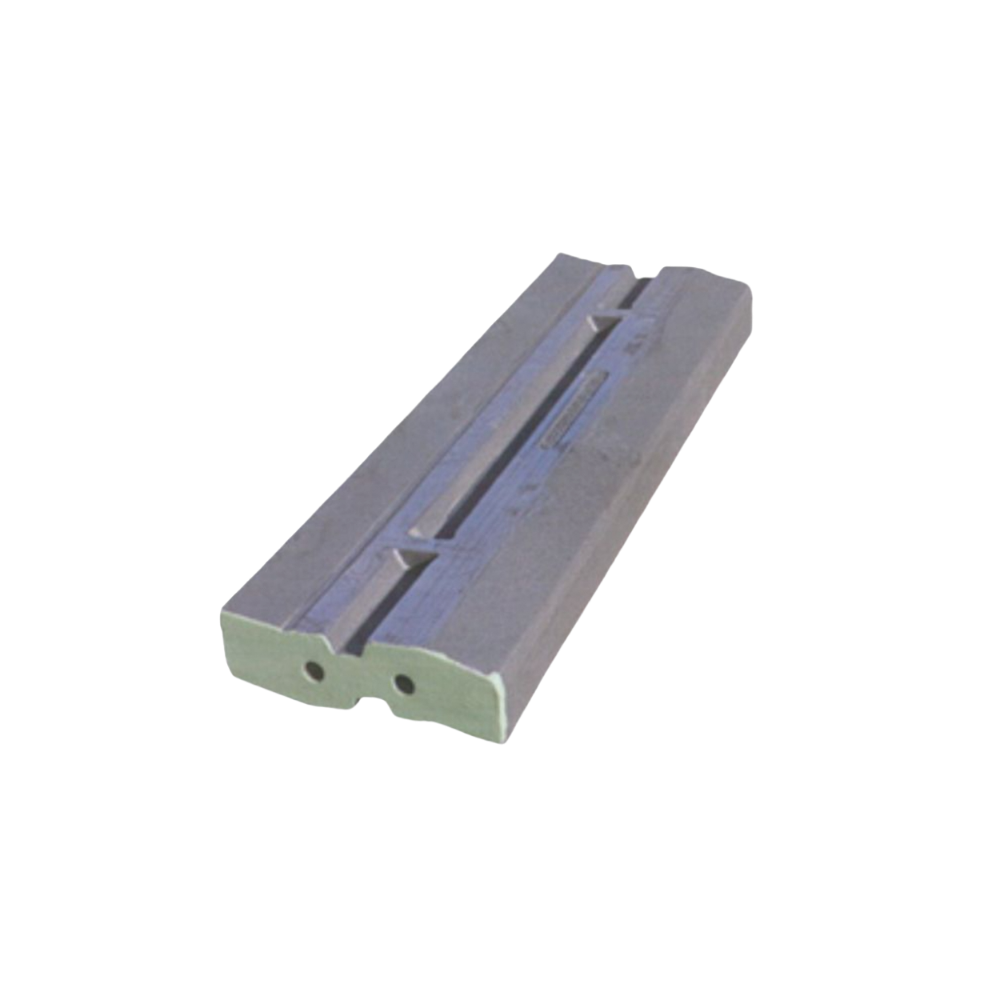

Concrete Mixing plant High-precision Scraper

-

Scraper-Concrete Mixing Plant

-

High Toughness Scraper For Concrete Mixing Plant

-

OEM Lining Plate For Concrete Mixing Plant

-

Concrete Mixing Plant Lining Plate

-

Concrete Mixing Plant High Wear-resistant Lining Plate

-

Concrete Mixing Plant Iron Casting Scraper

-

Concrete Mixing Plant Heat-resisting Lining Plate

-

Customizable Mixing Arm For Concrete Mixing Plant

-

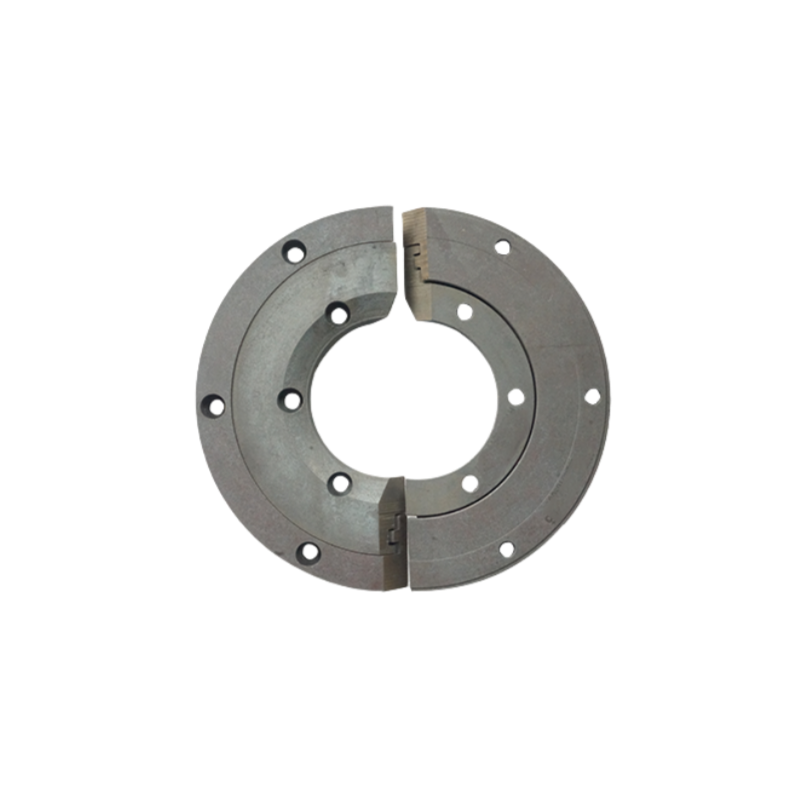

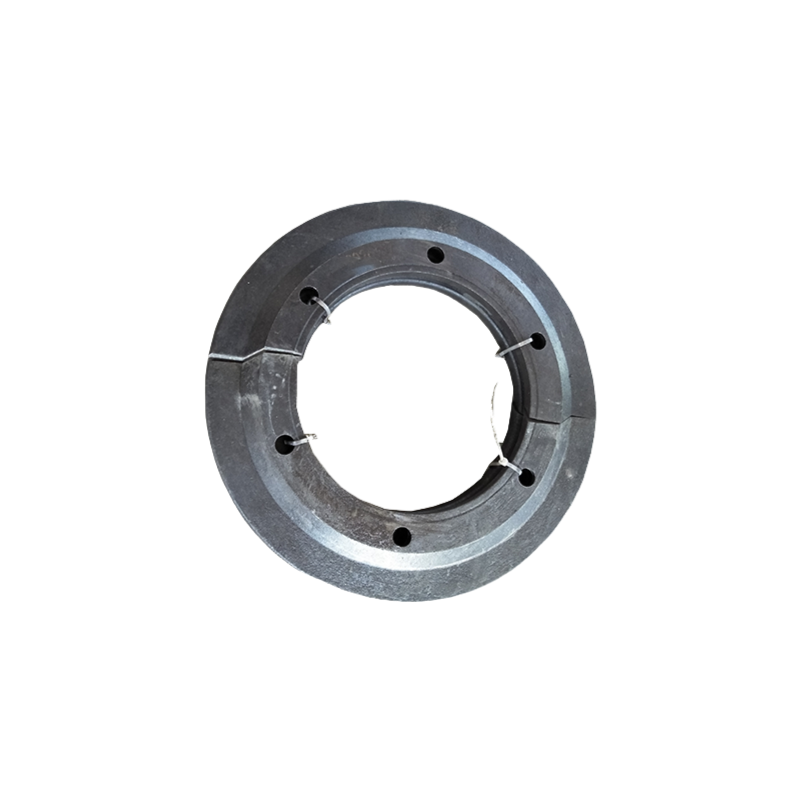

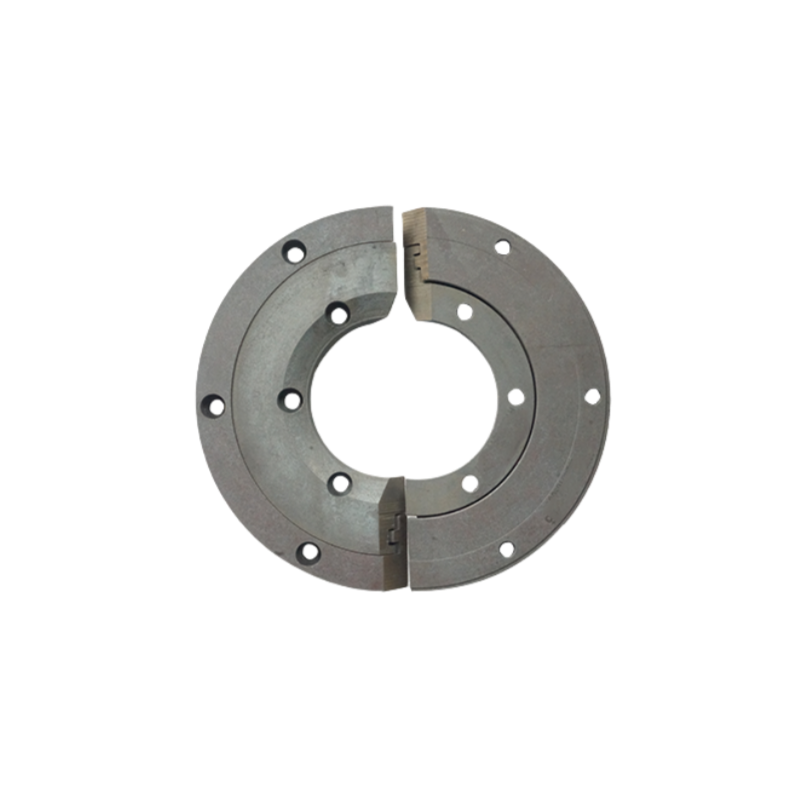

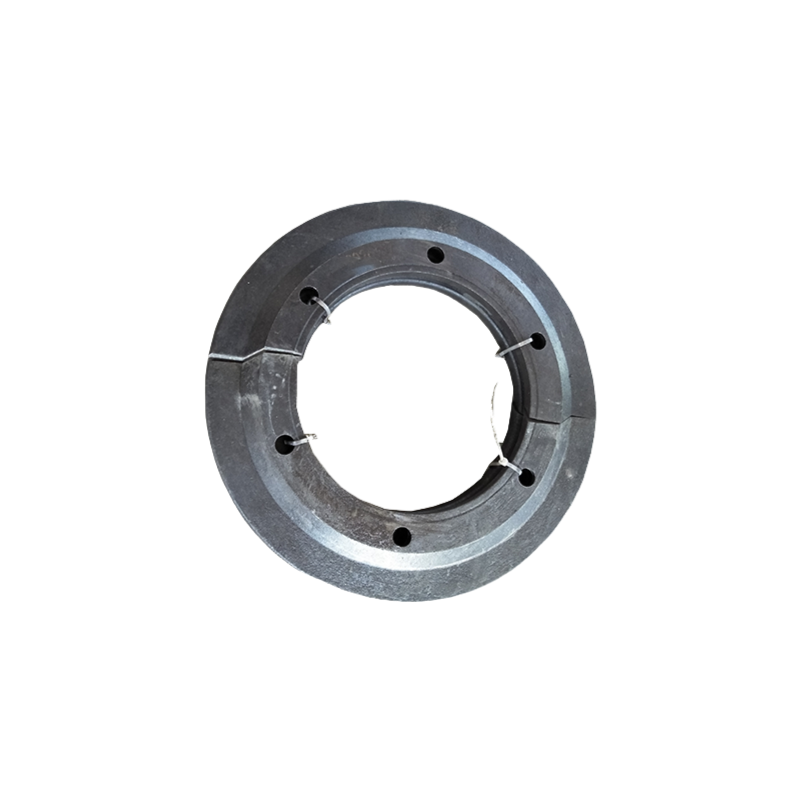

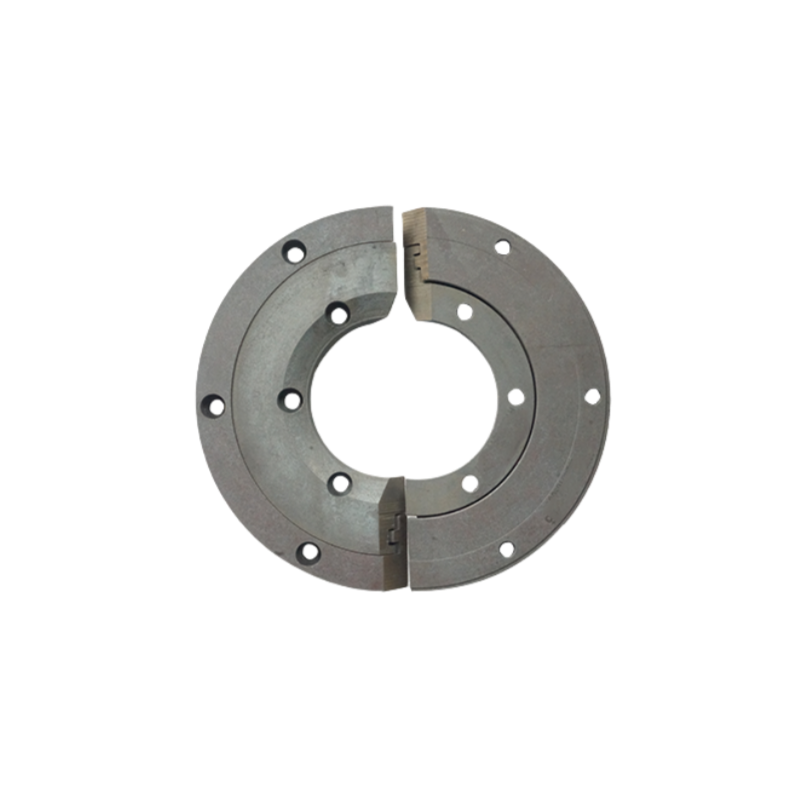

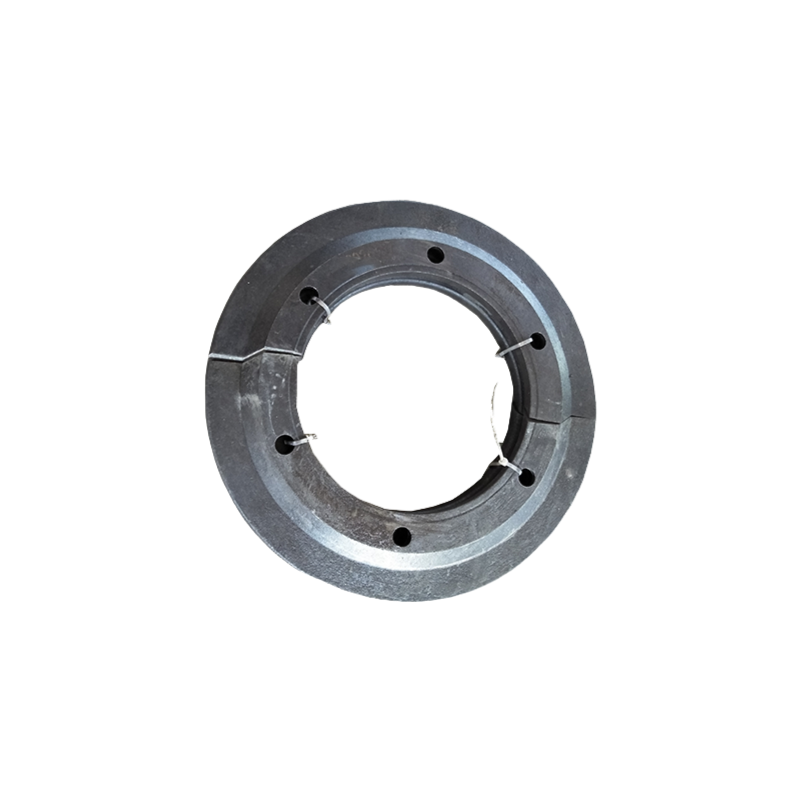

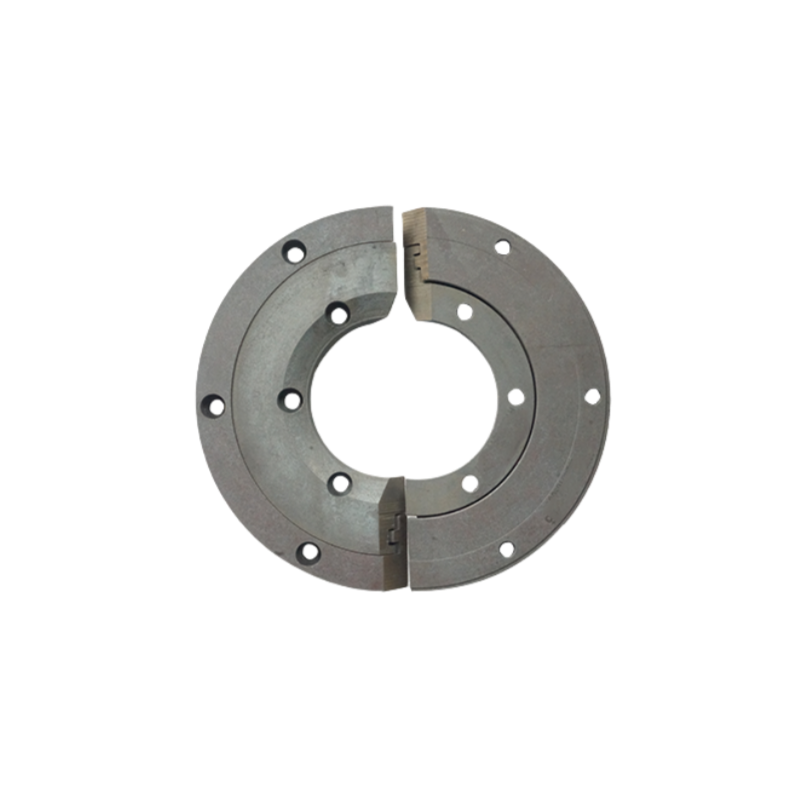

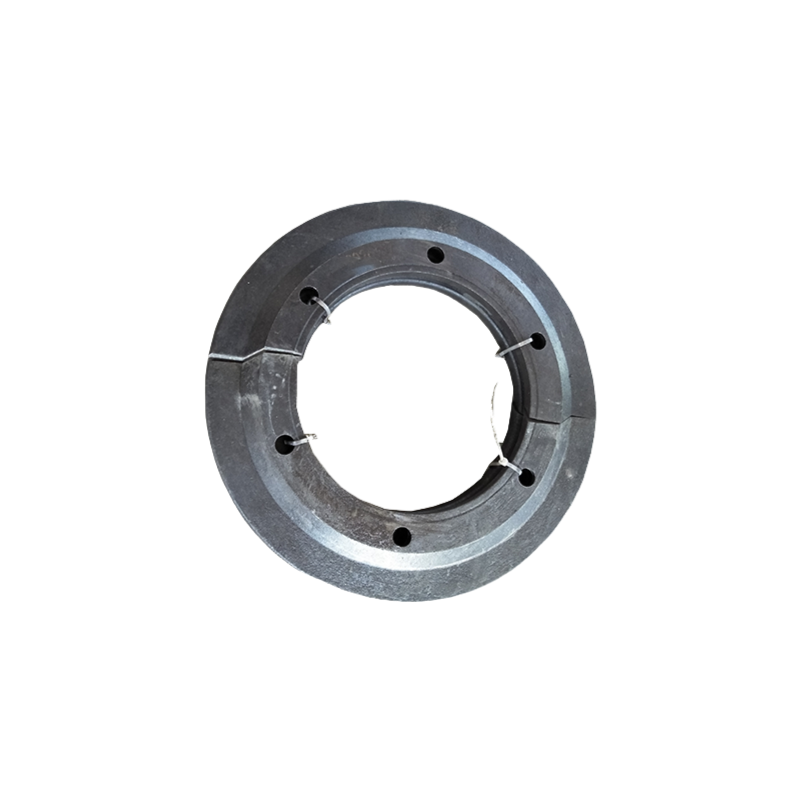

Concrete Mixing Plant Wear Resistant Seal

-

Concrete Pump Truck Bend Pipe

-

Concrete Pump Truck Straight Pipe

-

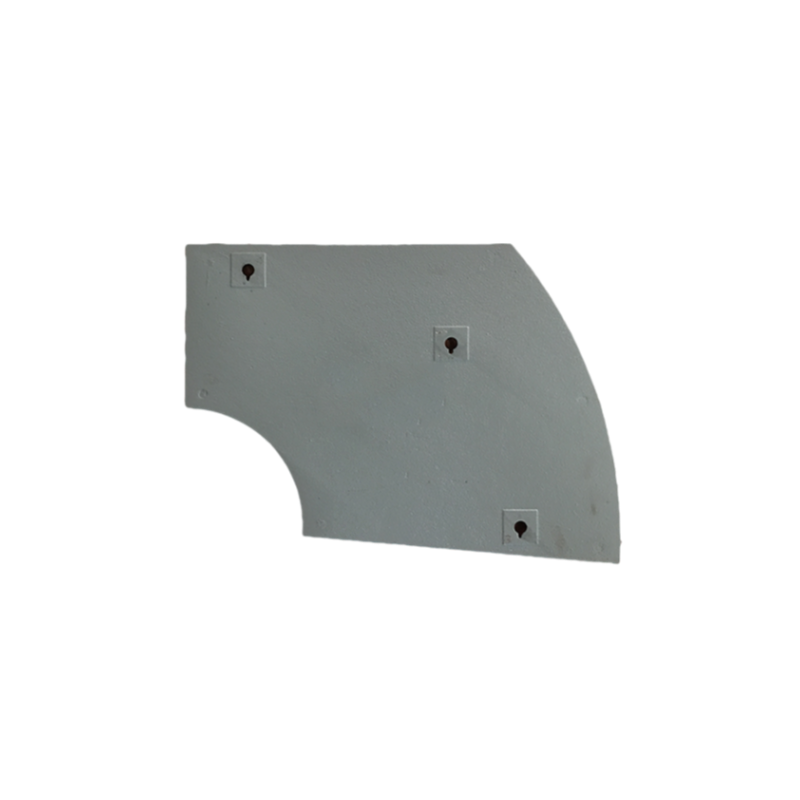

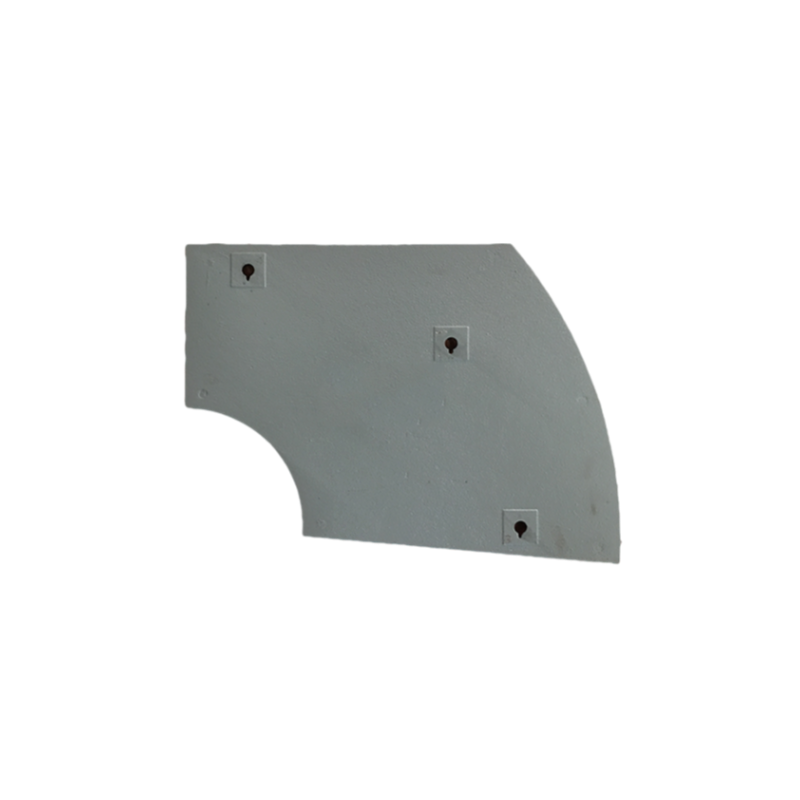

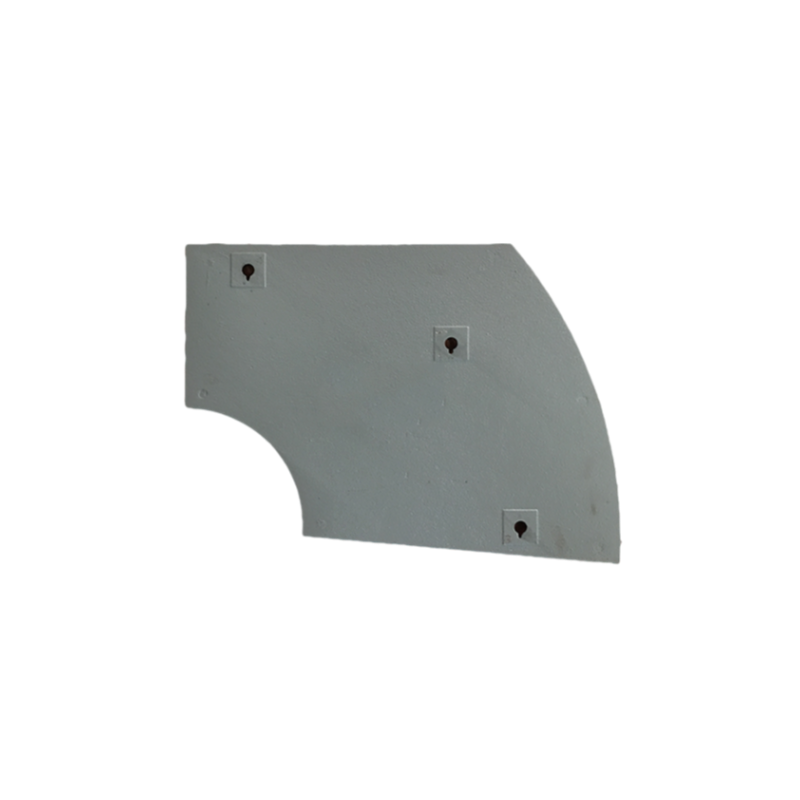

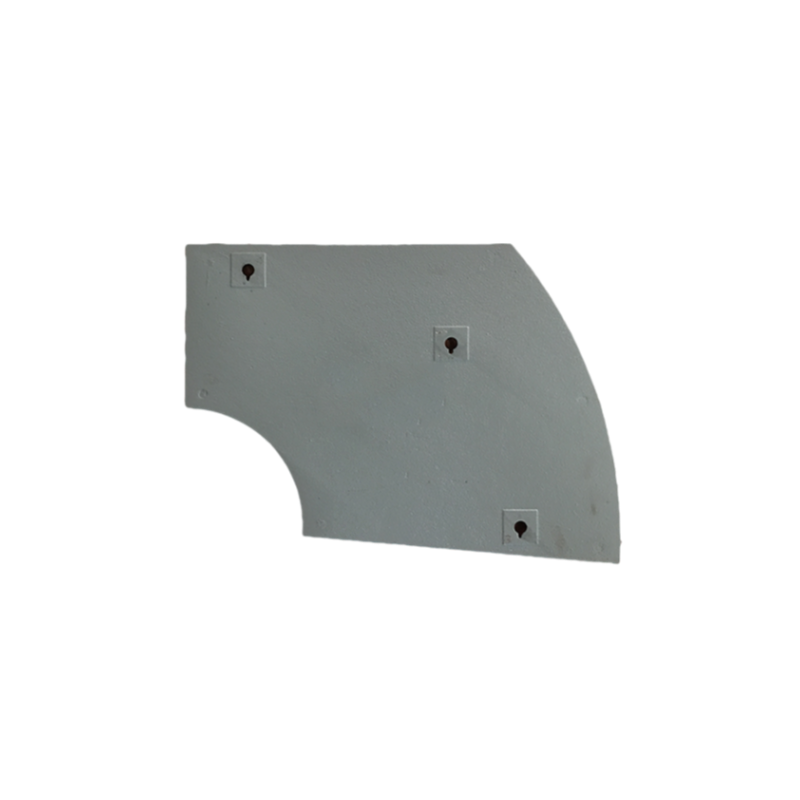

Discharge Door ARC Liner

-

Lining Plate-Concrete Machinery

-

High Temperature Tolerance Lining Plate

-

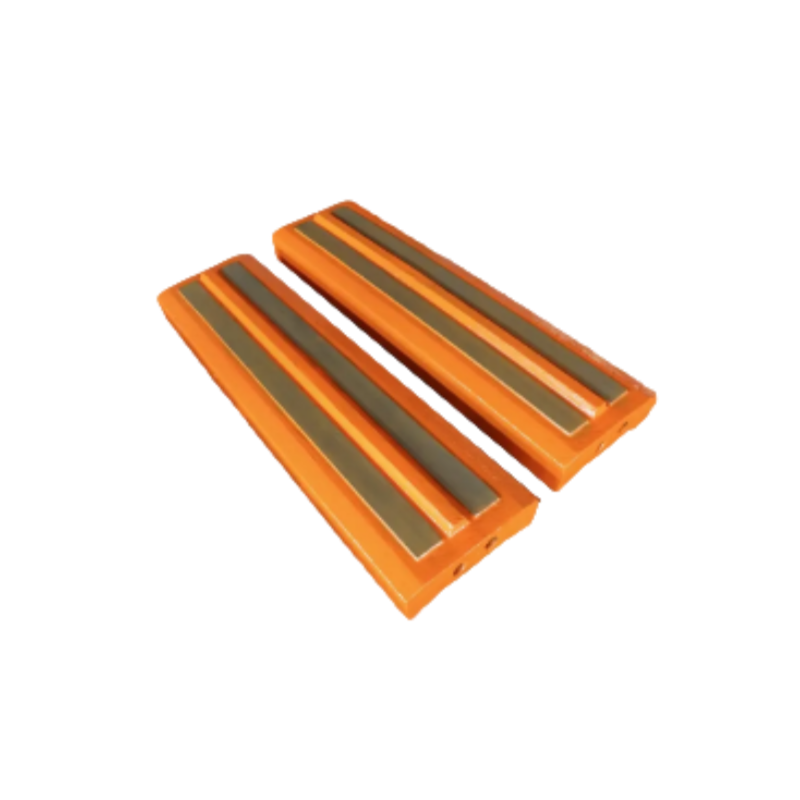

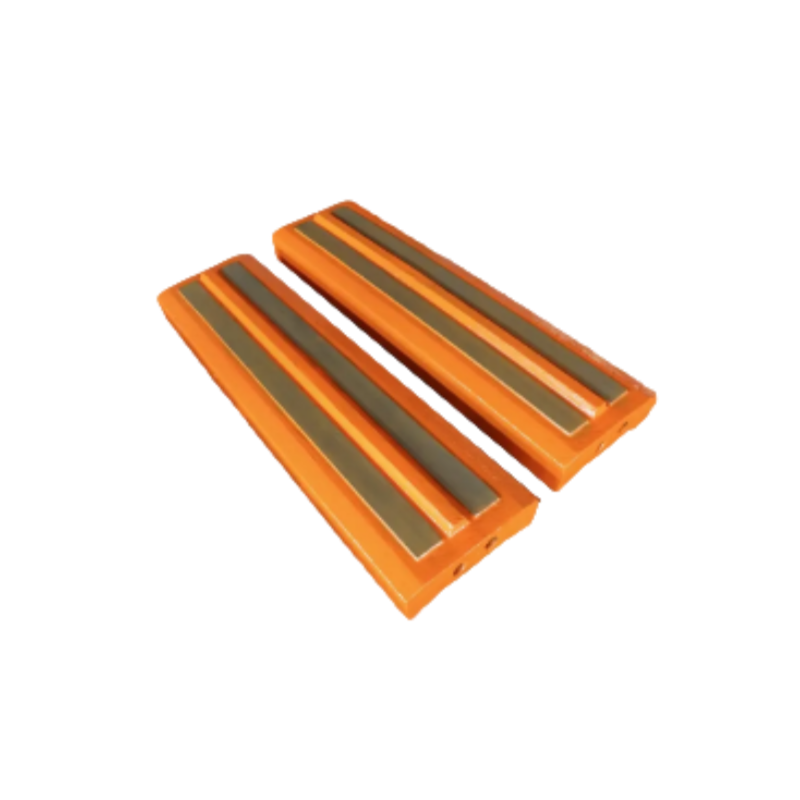

Economical & Corrosion Resistance Blade

-

Concrete Mixing Plant Scraper Wear Parts

-

Strong Wear-resistant Seal

-

Diverse Choices Lining Plate

-

Concrete Mixing Plant Wear Resistant Scraper

-

Diverse Choices Lining Plate

-

Concrete Scraper High Efficiency

-

High Strength Lining Plate

-

Corrosion Resistance Scraper

-

Lining Plate For Asphalt Mixing Plant

-

Asphalt Paver Wear-resistant Spiral Blade

-

Lining Plate-Asphalt Mixing Plant

-

Asphalt Side Lining parts

-

Asphalt Machinery Series

-

Mixing Arm-Asphalt Mixing Plant

-

Spiral Blade For Asphalt Mixing Plant

-

Sealing element-Asphalt Mixing Plant

-

Scraper-Asphalt Mixing Blade

-

Strong Wear Resistance Lining Plate

-

Good Toughness Lining Plate

-

Spiral Blade-Asphalt Mixing Plant

-

High Temperature Resistance Plate

-

Good Strength Lining Plate

-

Asphalt Side Lining

-

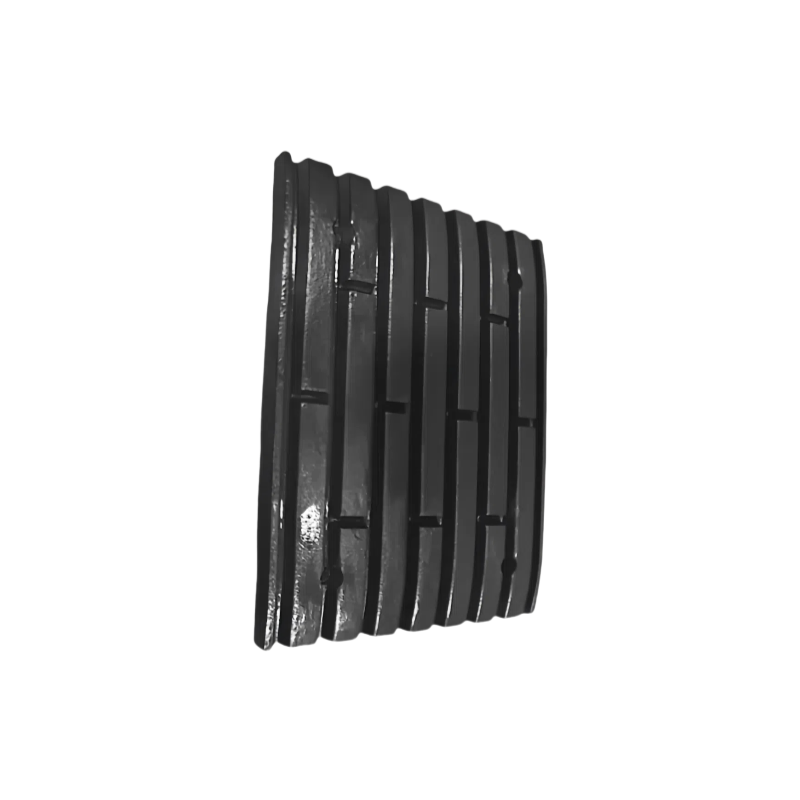

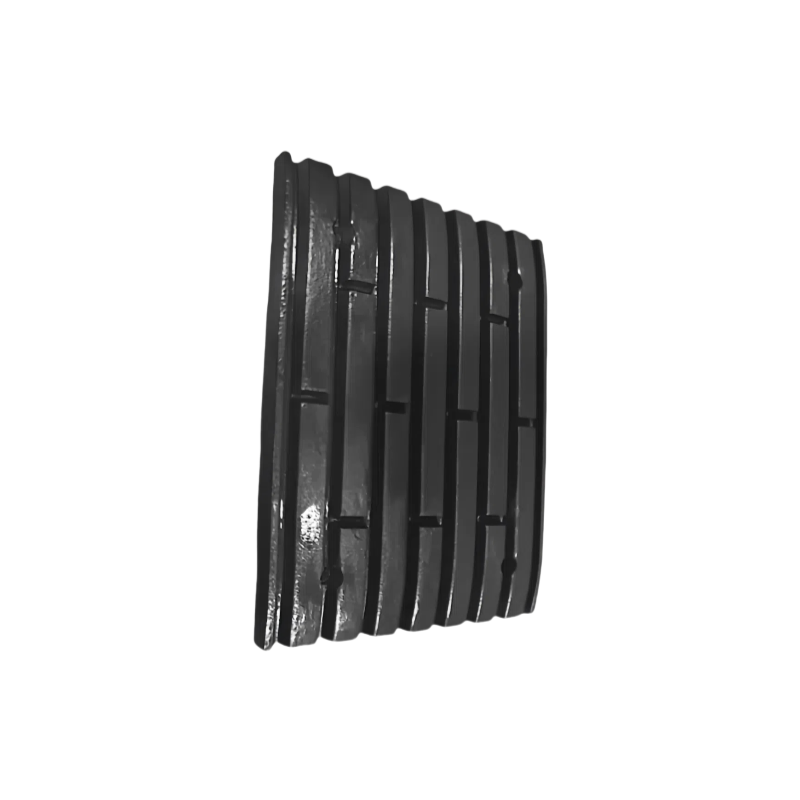

Blow Bar For Smelting Equipment

-

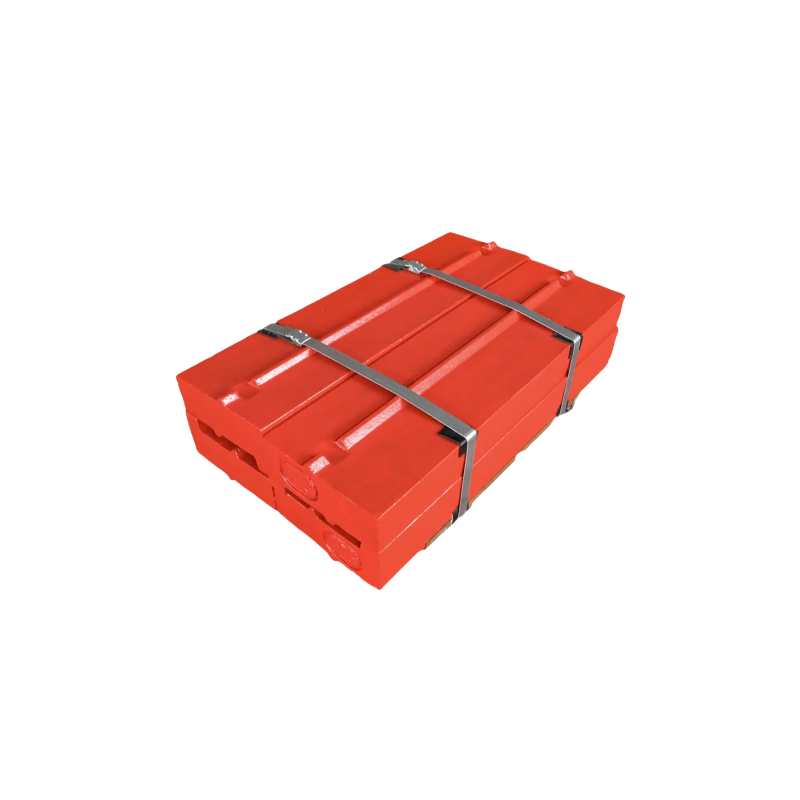

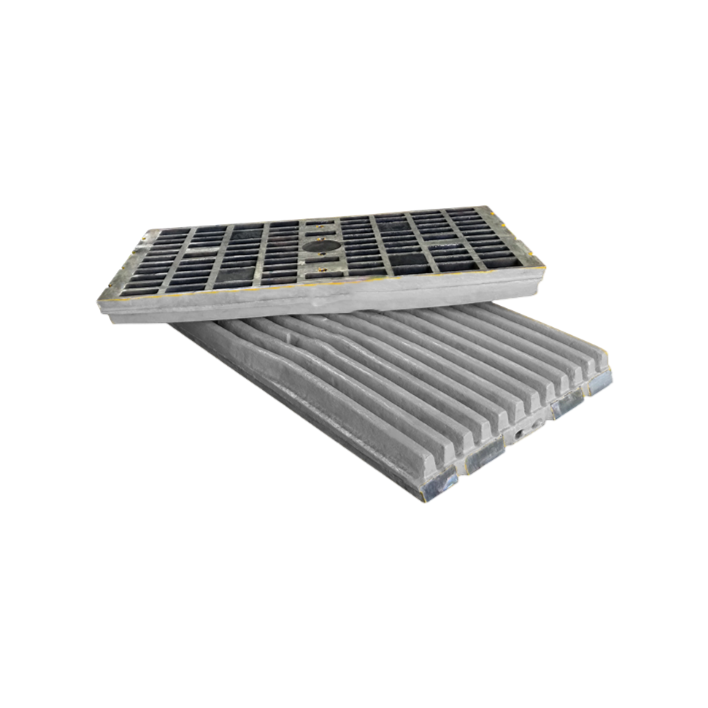

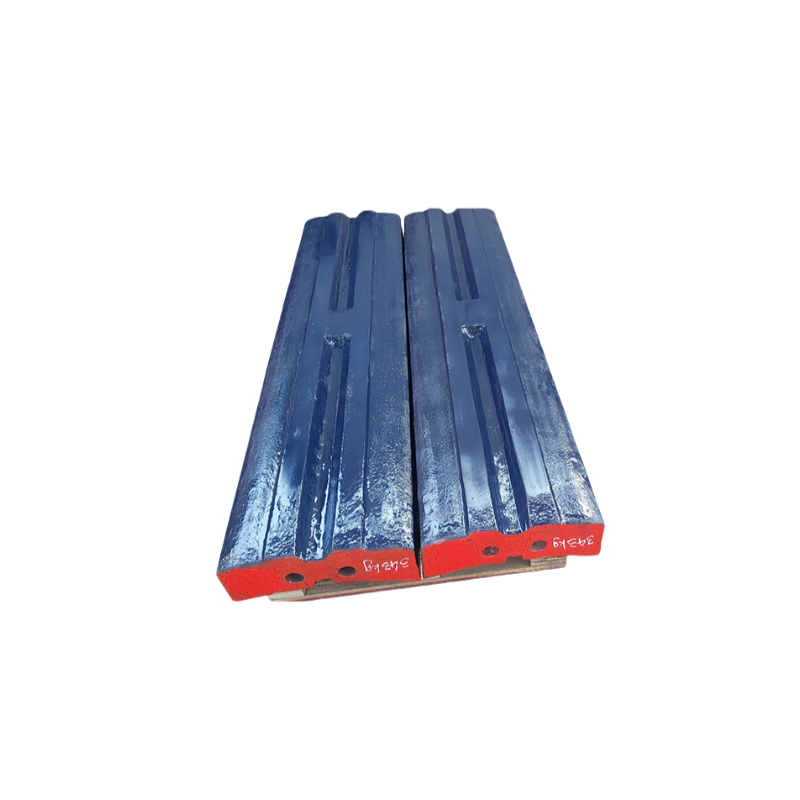

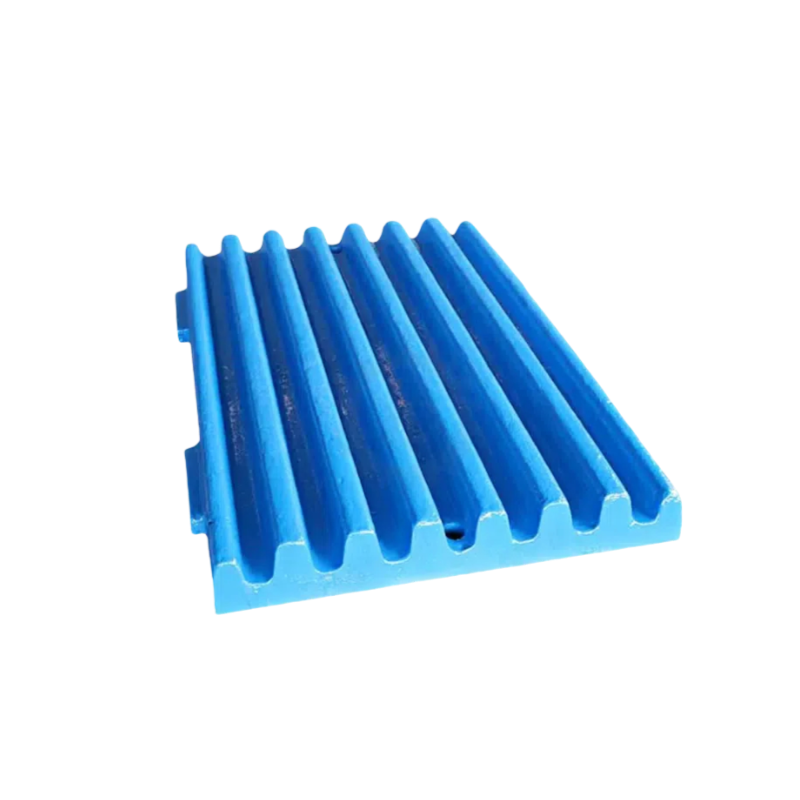

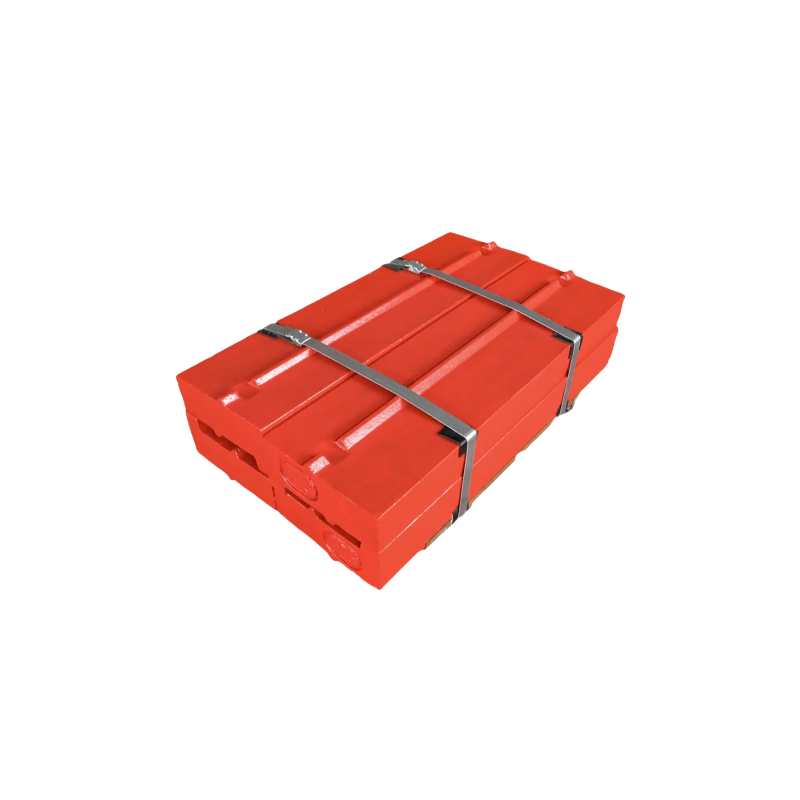

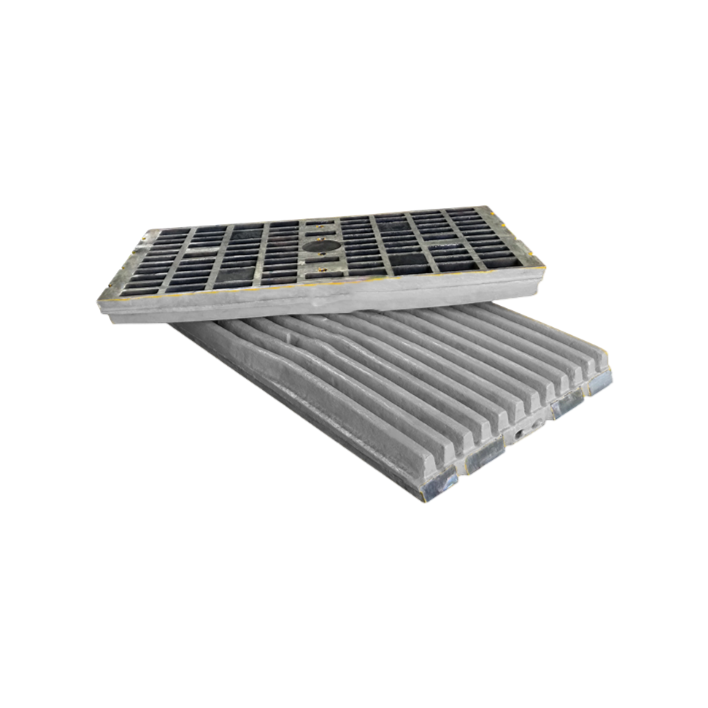

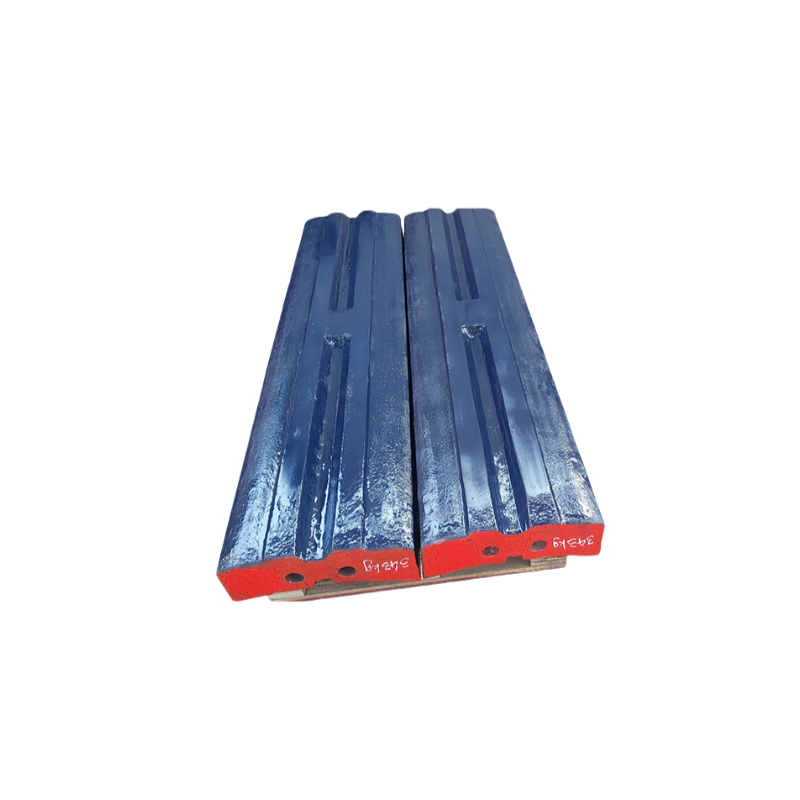

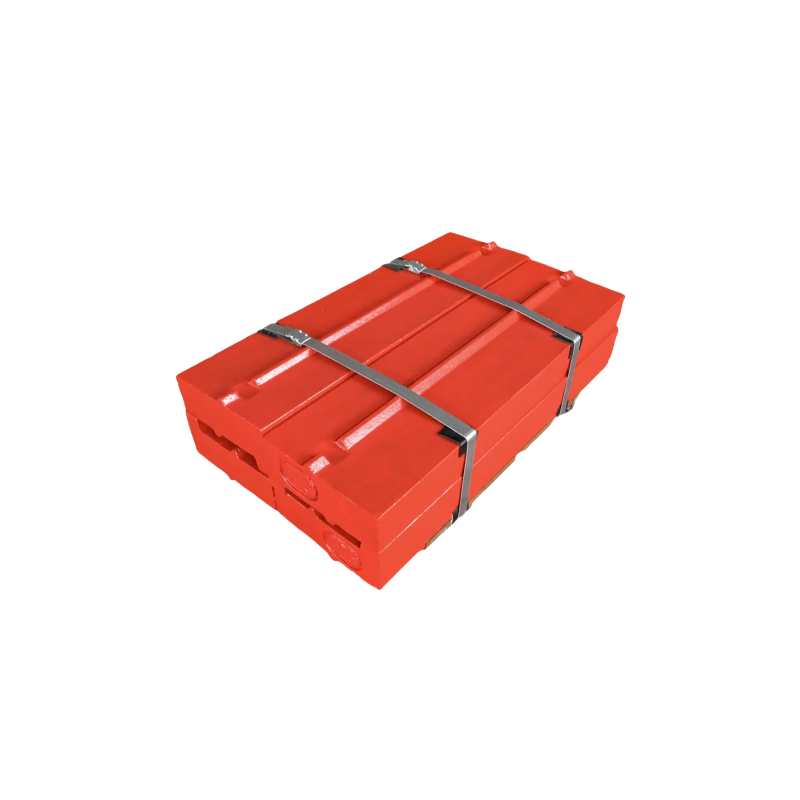

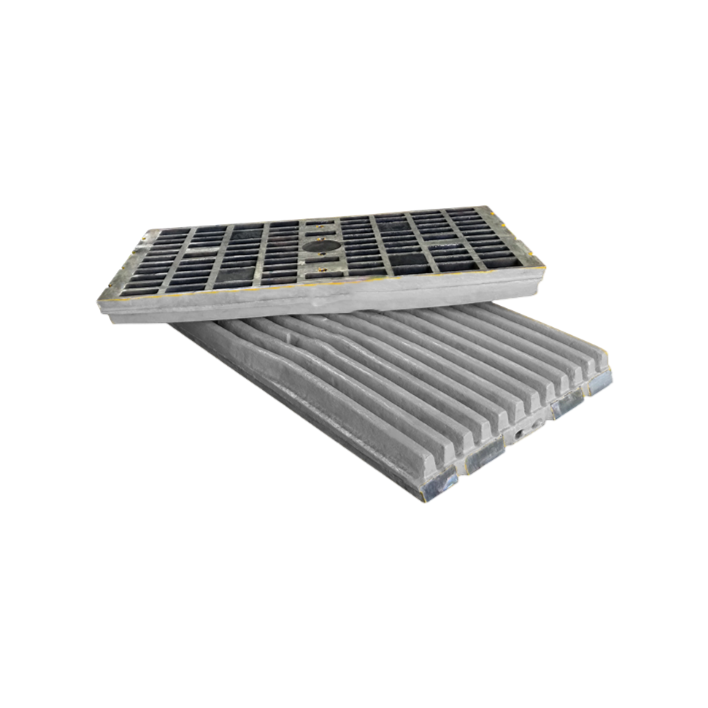

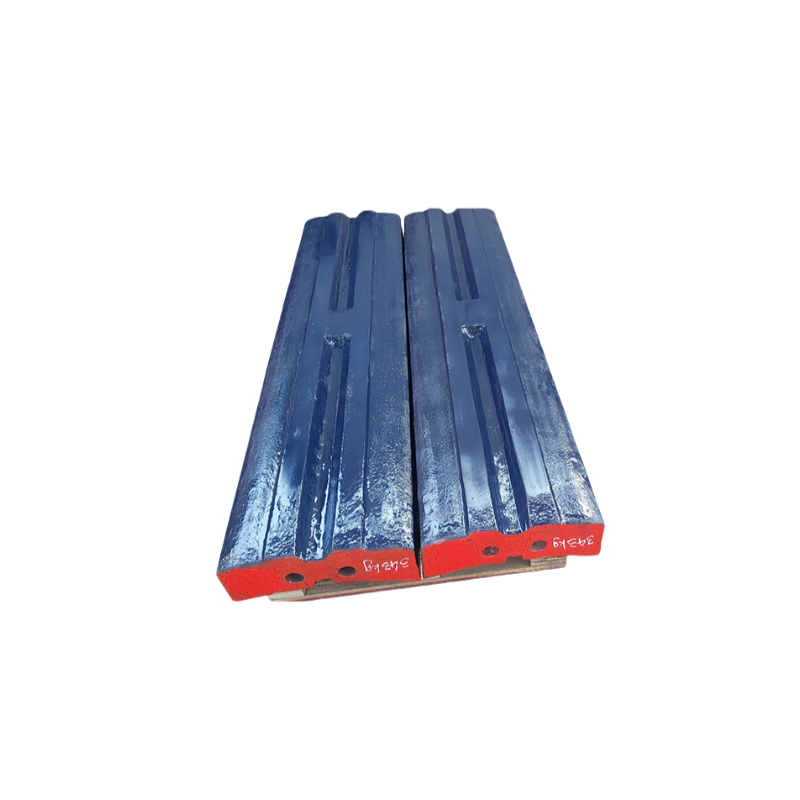

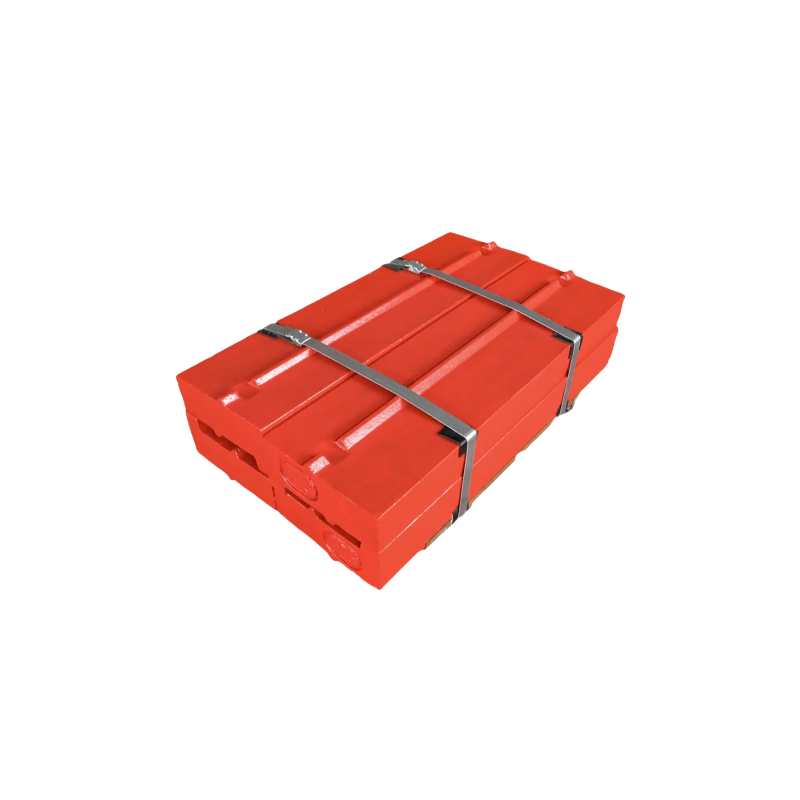

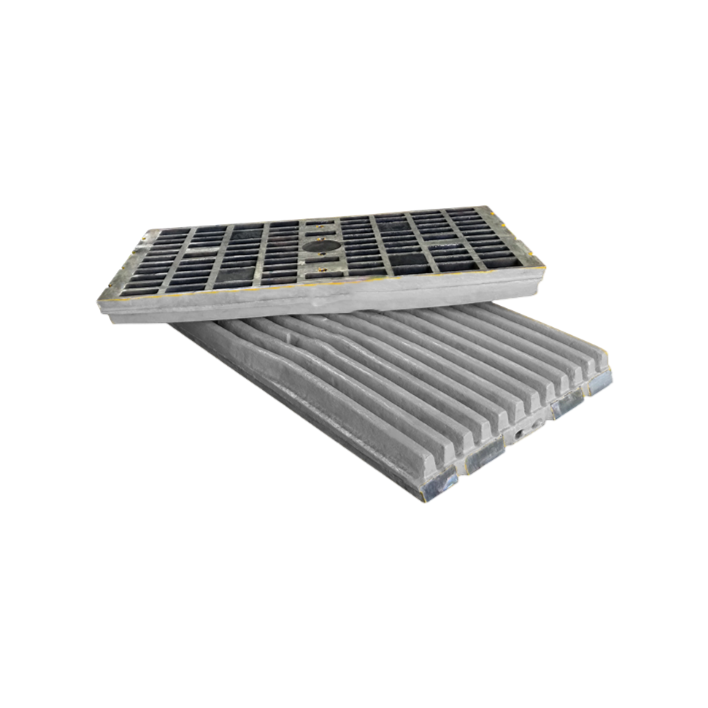

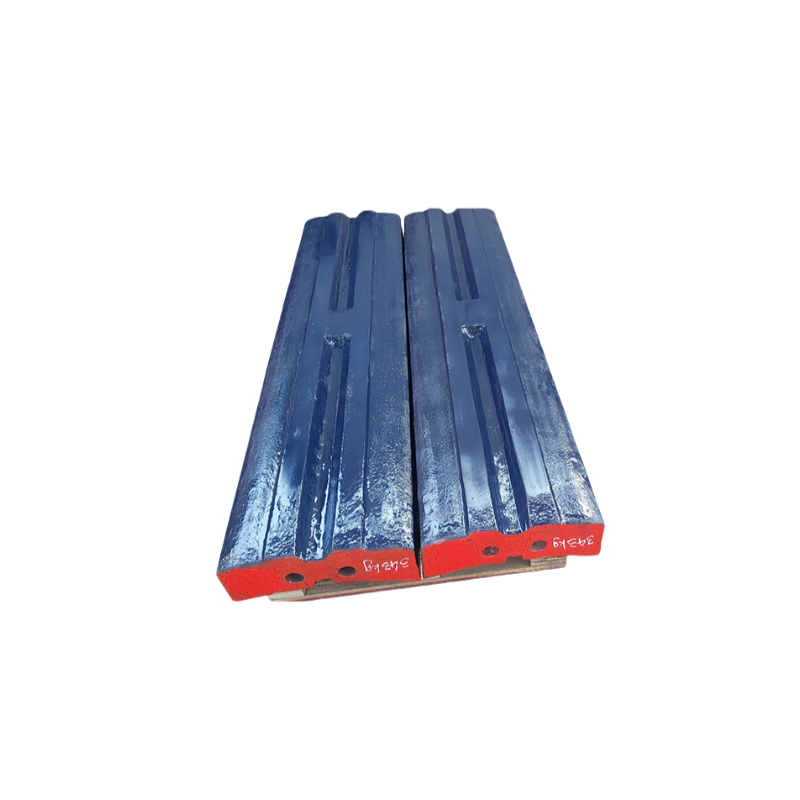

High Quality Wear-Resistant Crusher Jaw Plate

-

High Quality Impact Crusher Blow Bar

-

Premium Impact Crusher Blow Bar

-

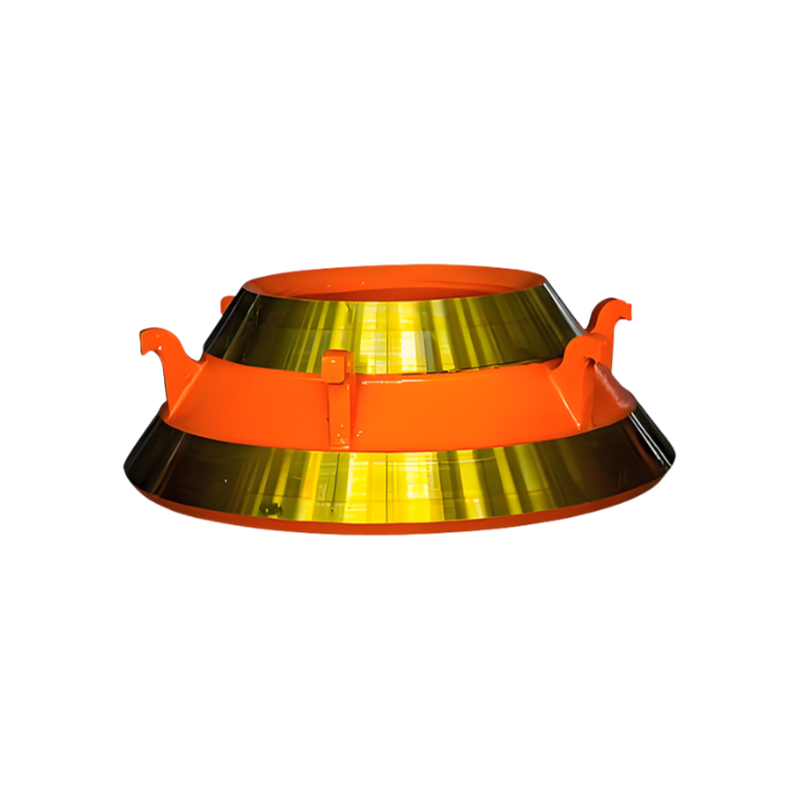

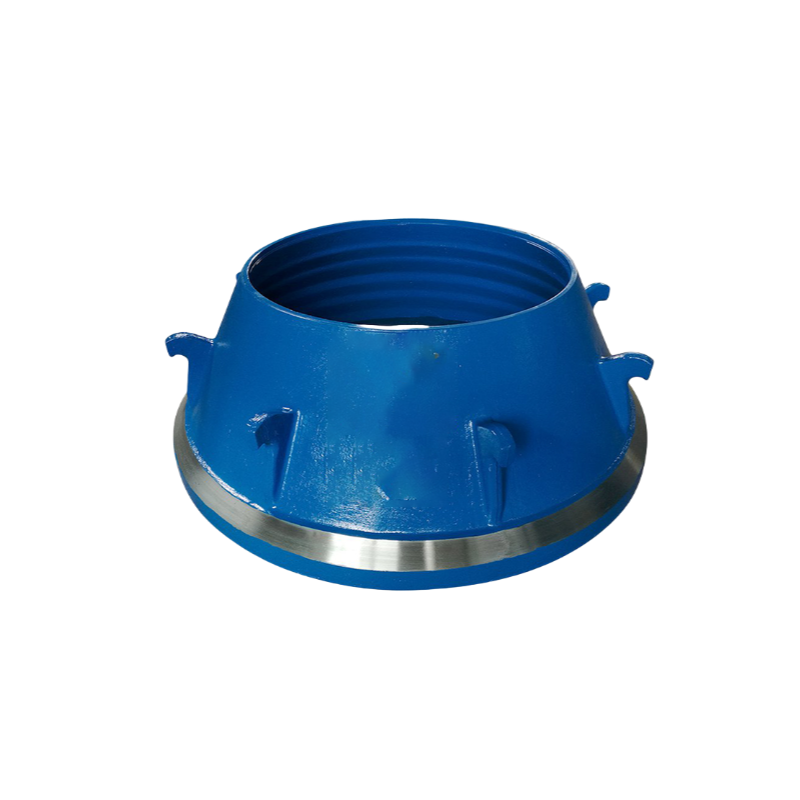

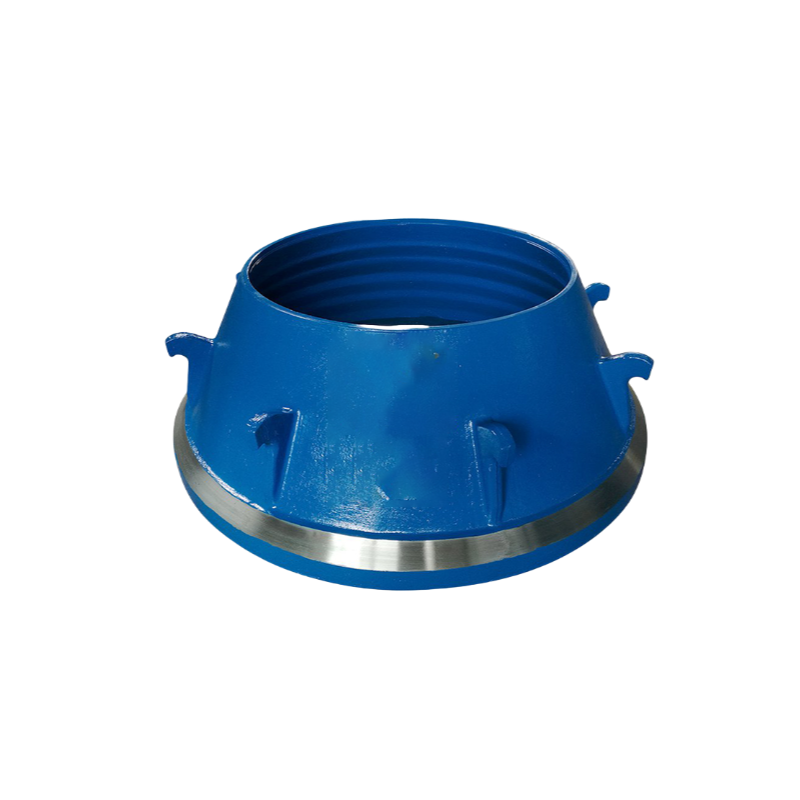

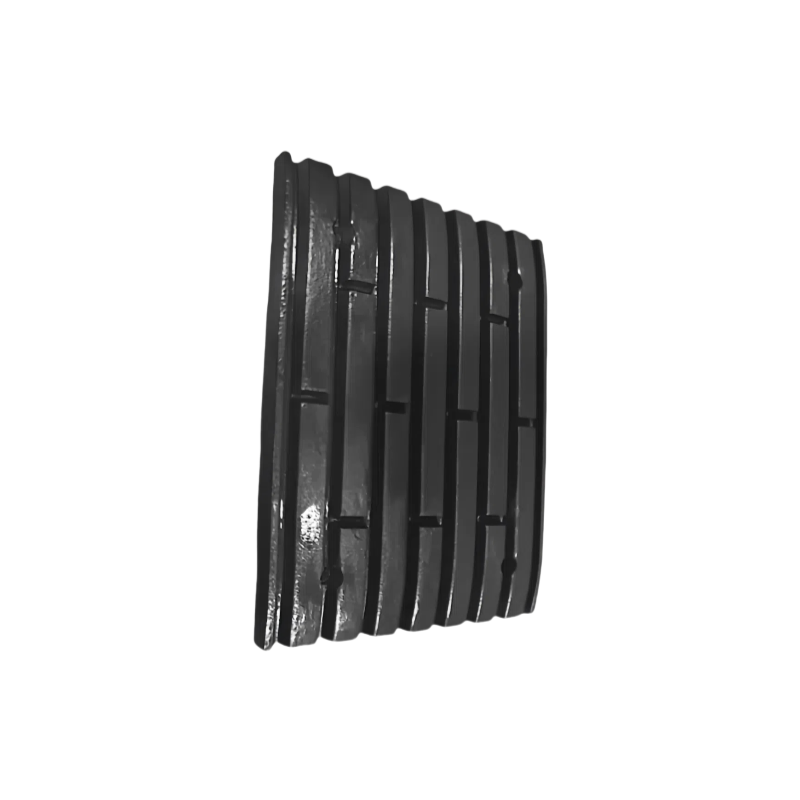

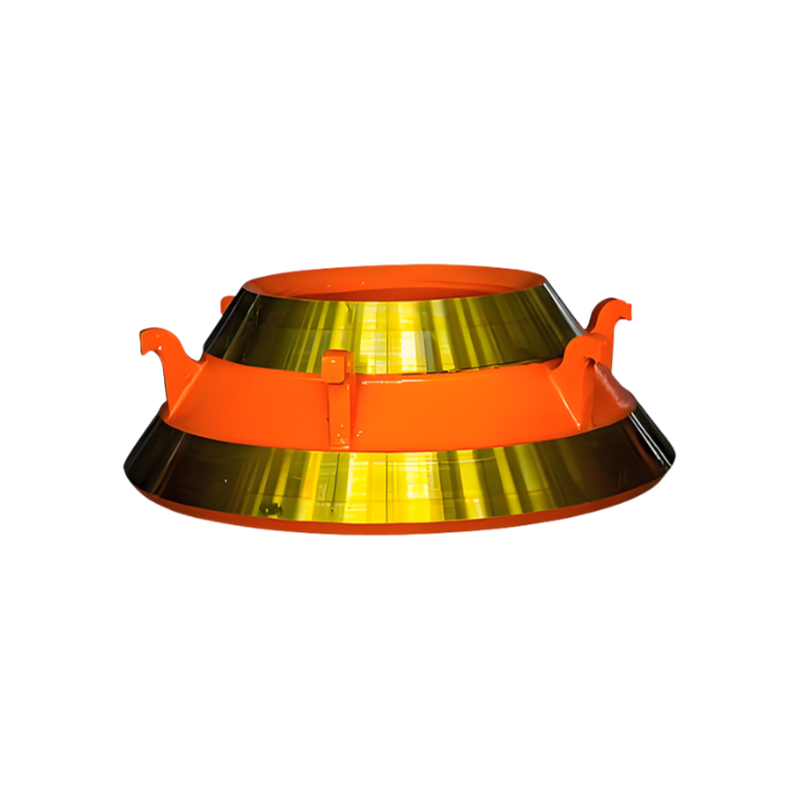

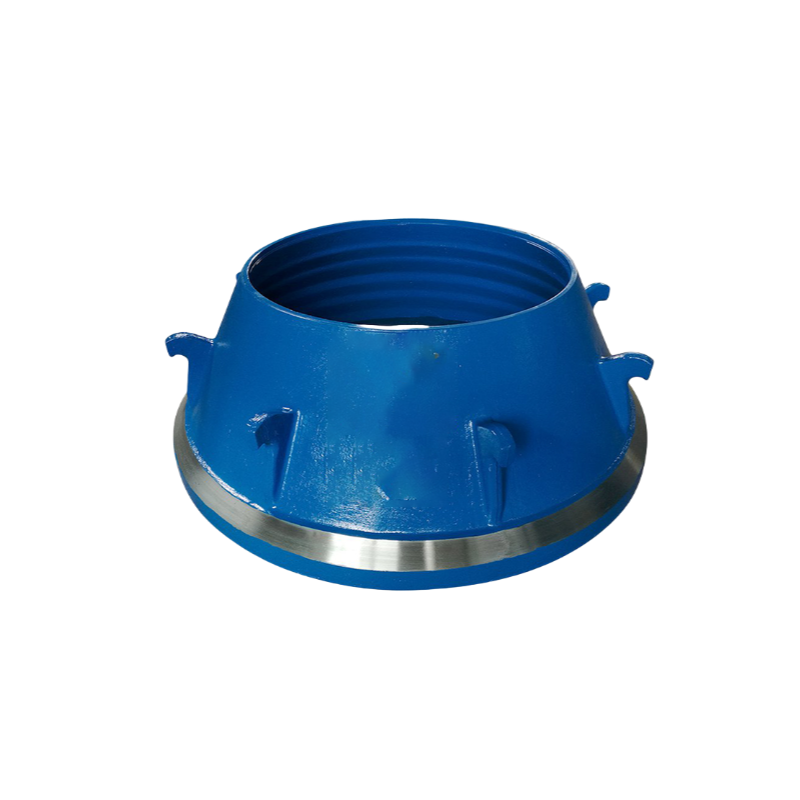

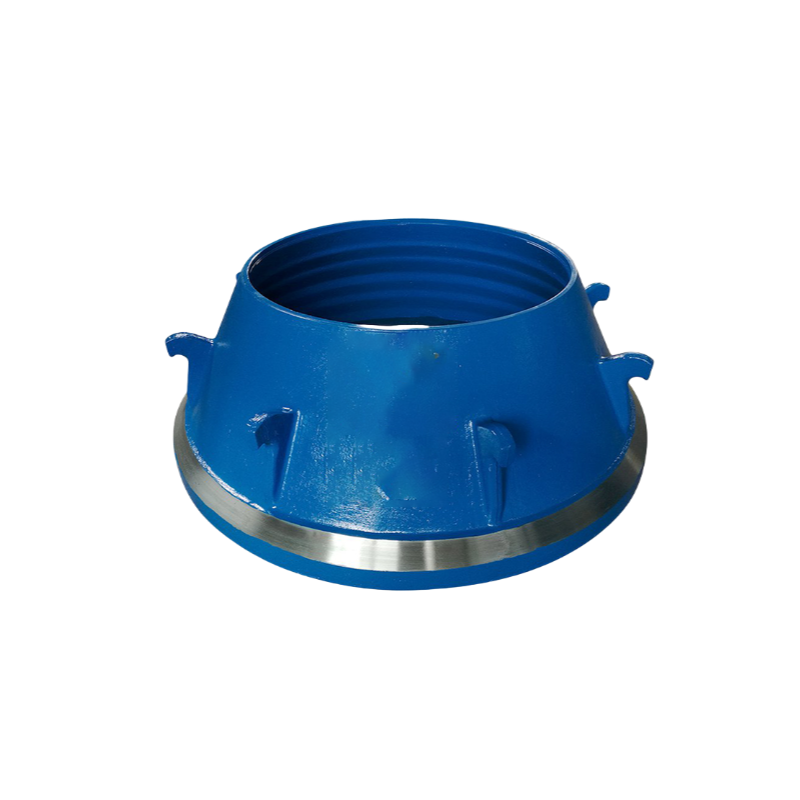

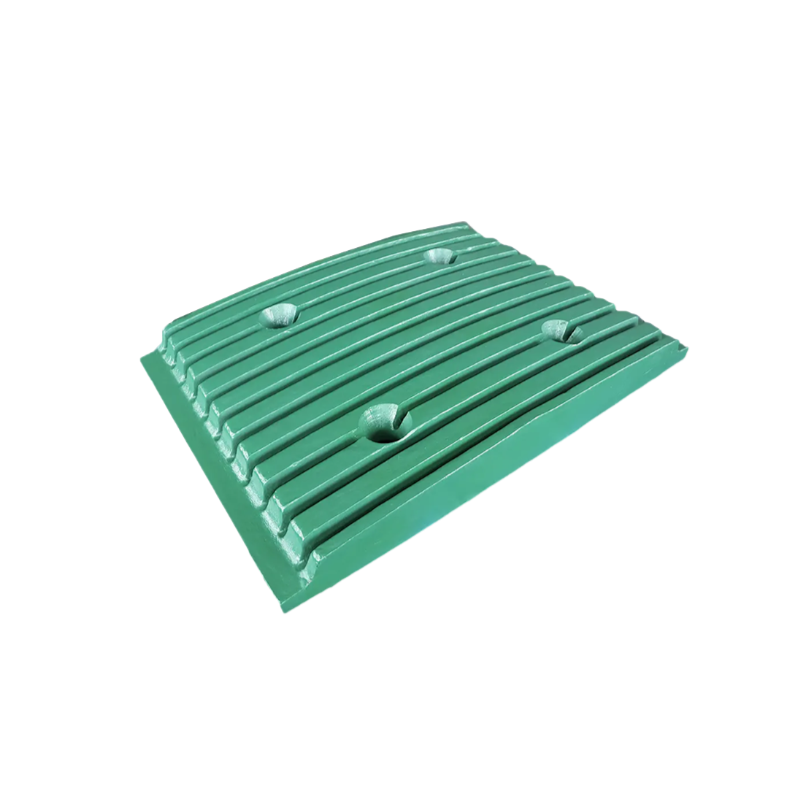

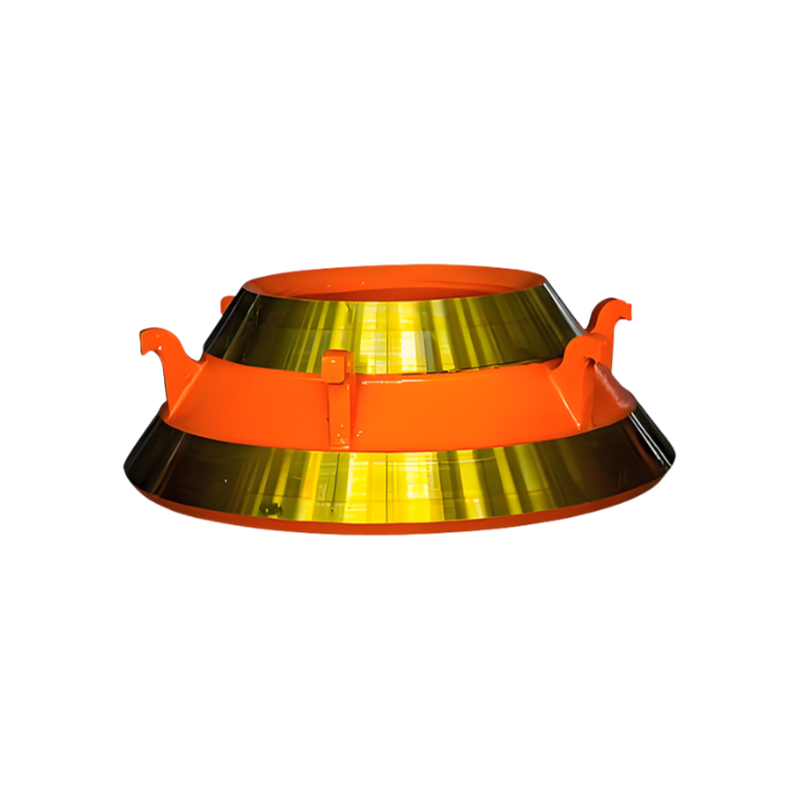

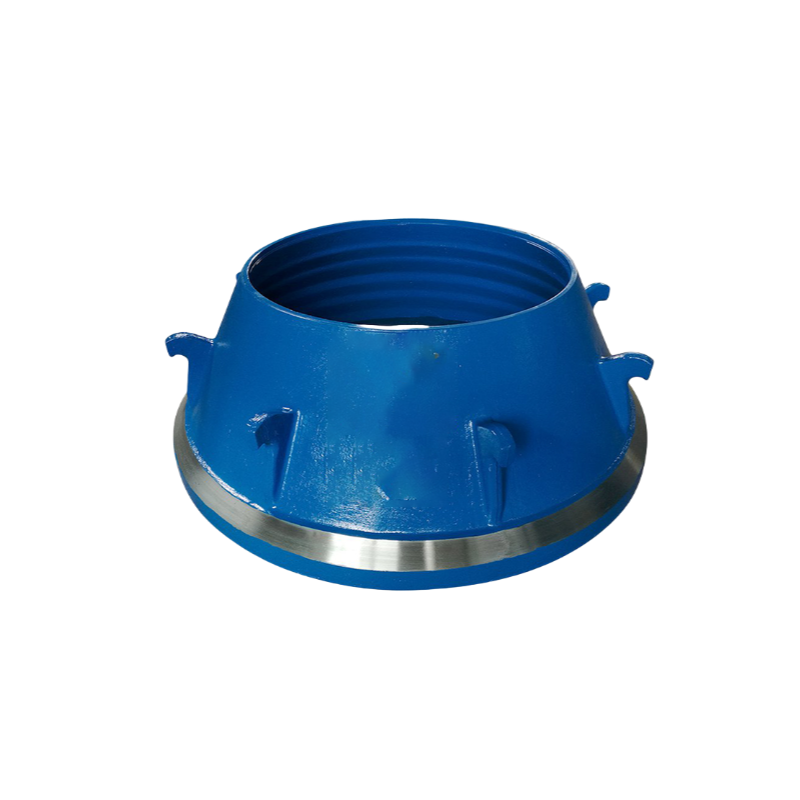

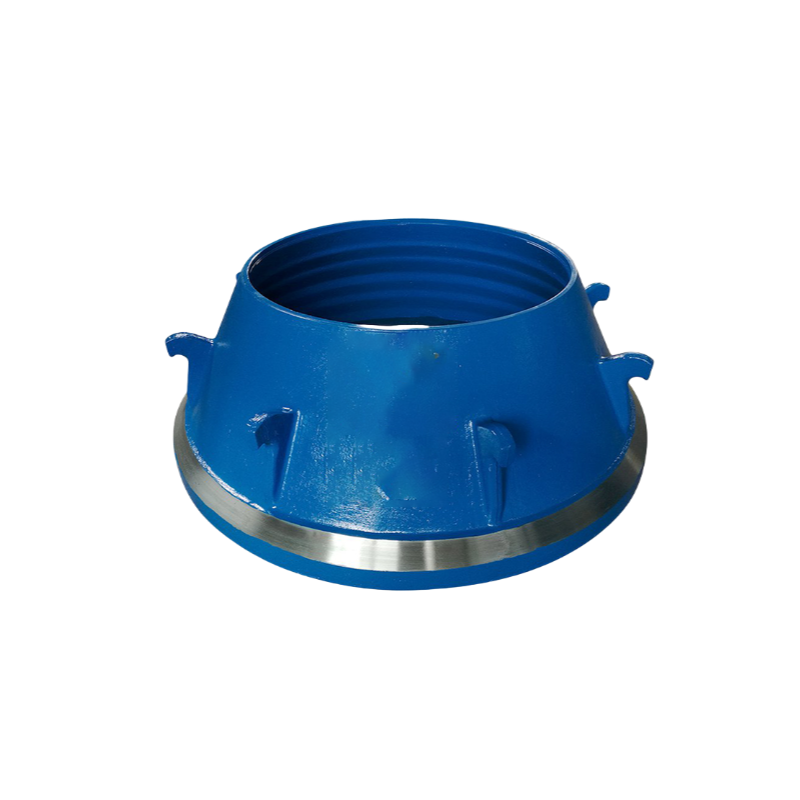

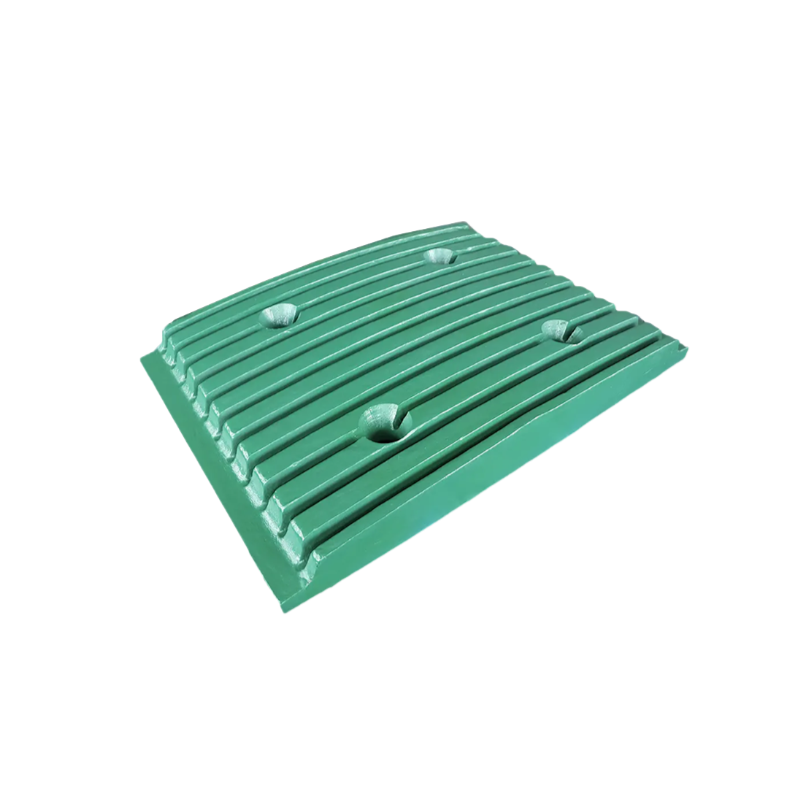

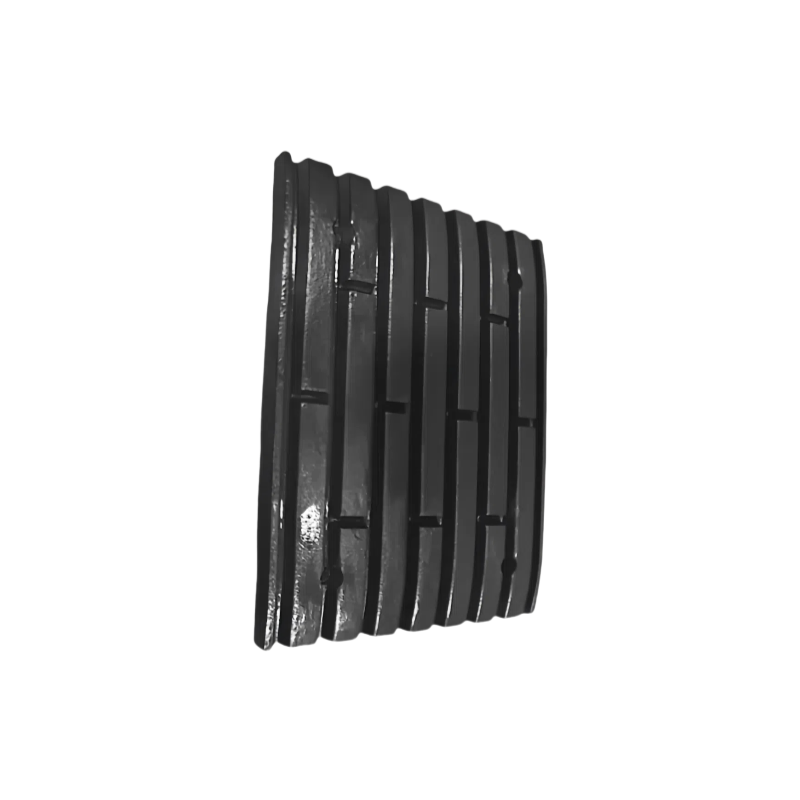

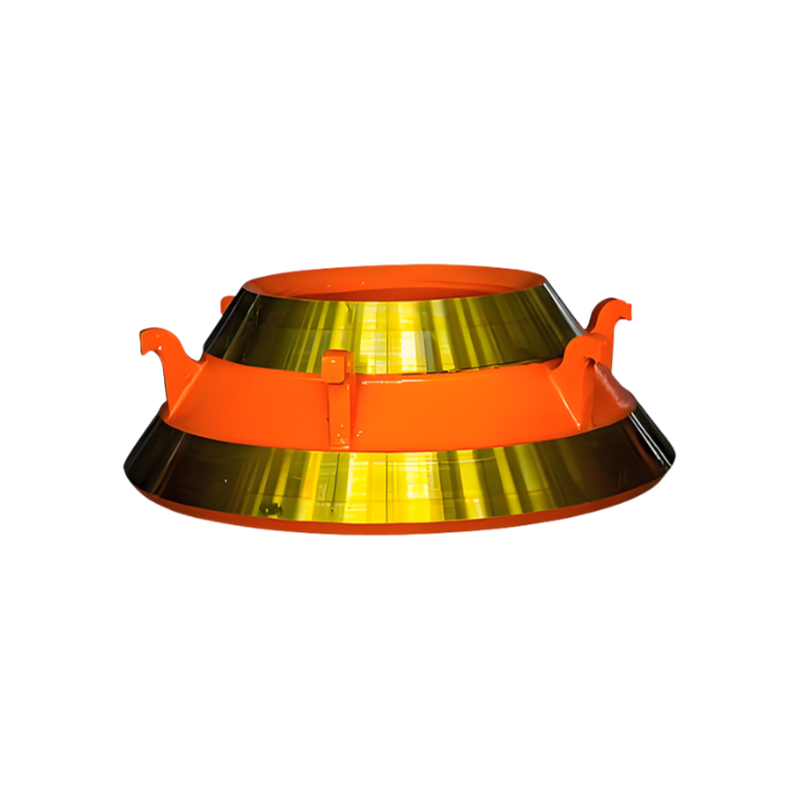

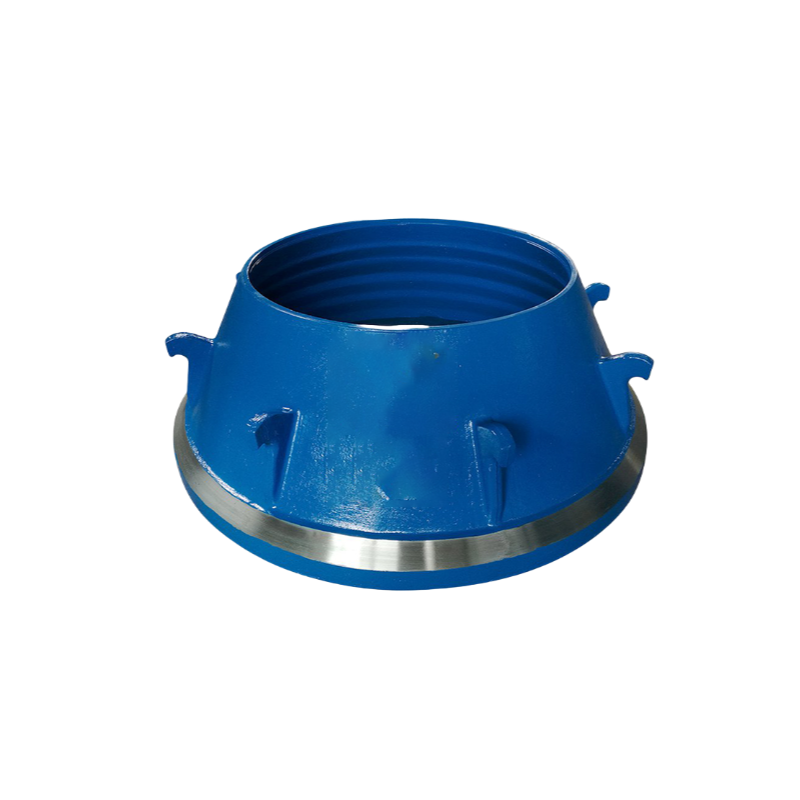

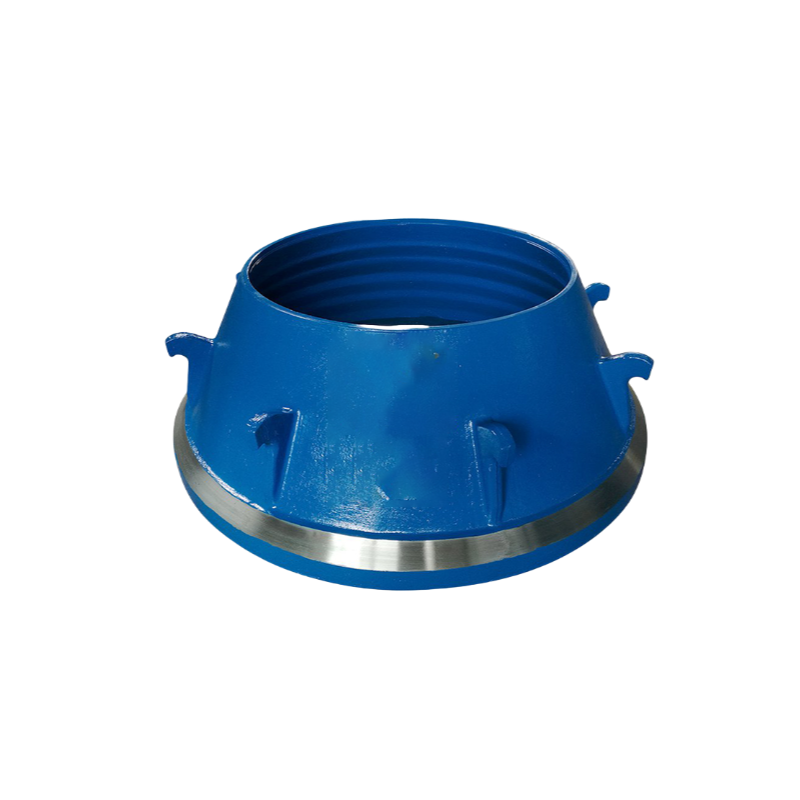

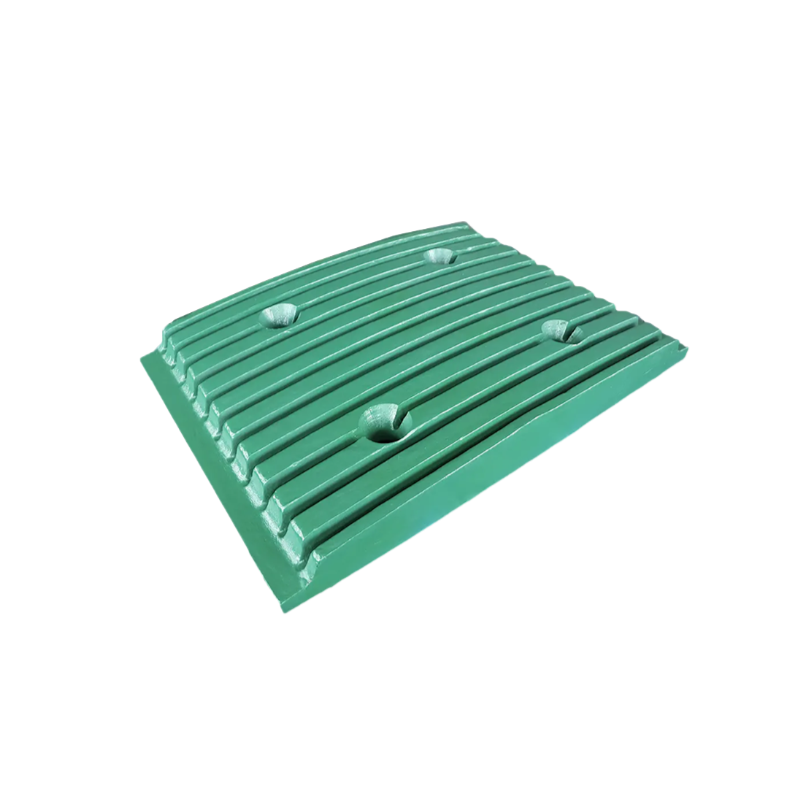

Cone crusher Bowl Liner

-

Powerful Cone Crusher Bowl Liner

-

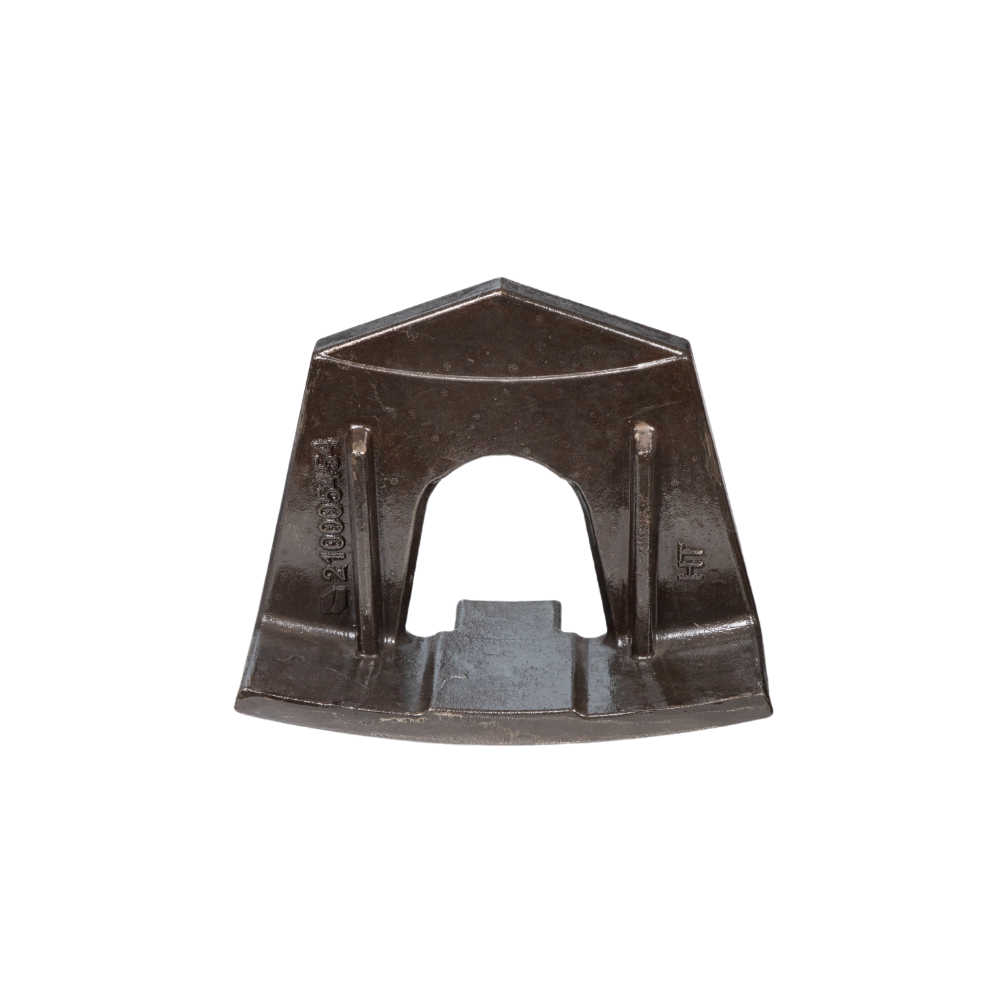

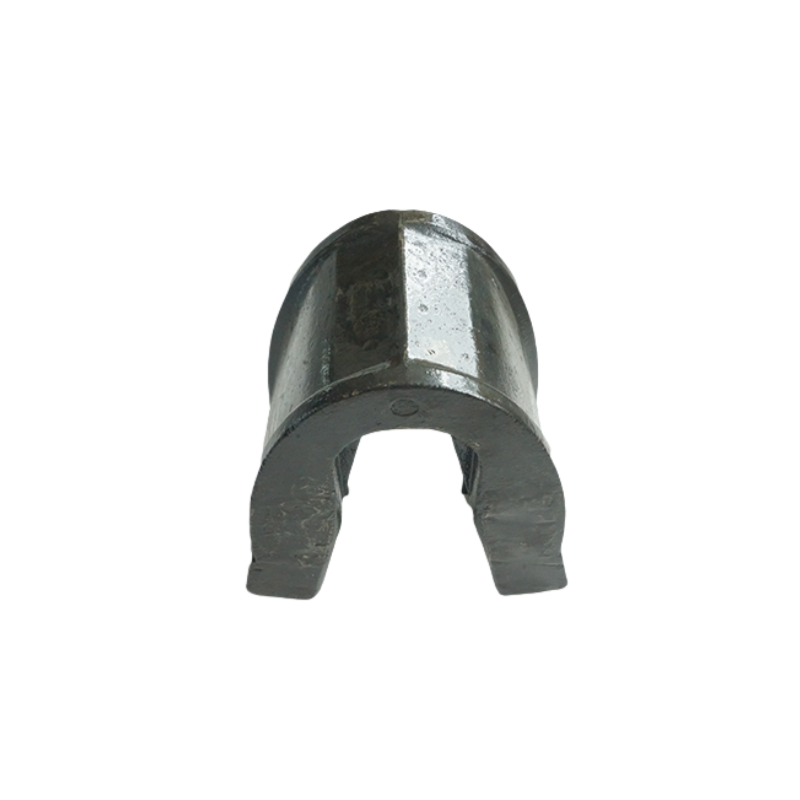

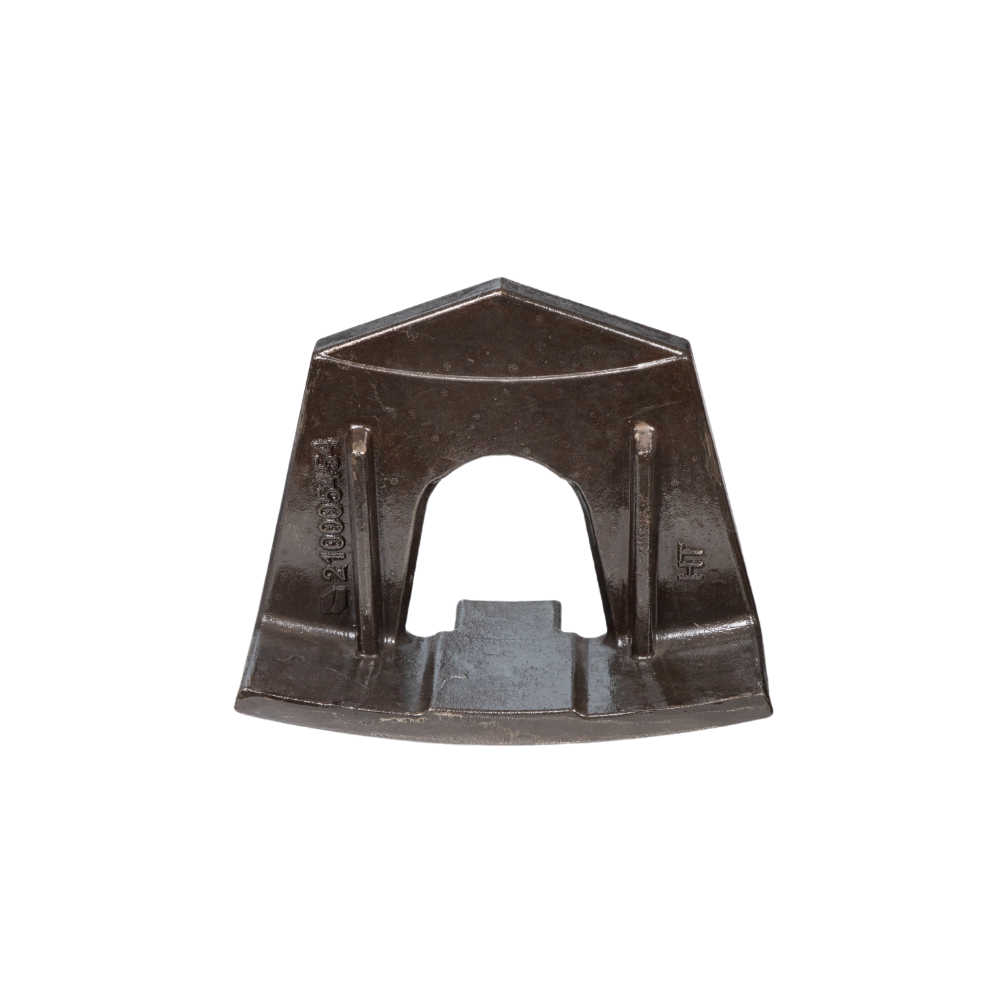

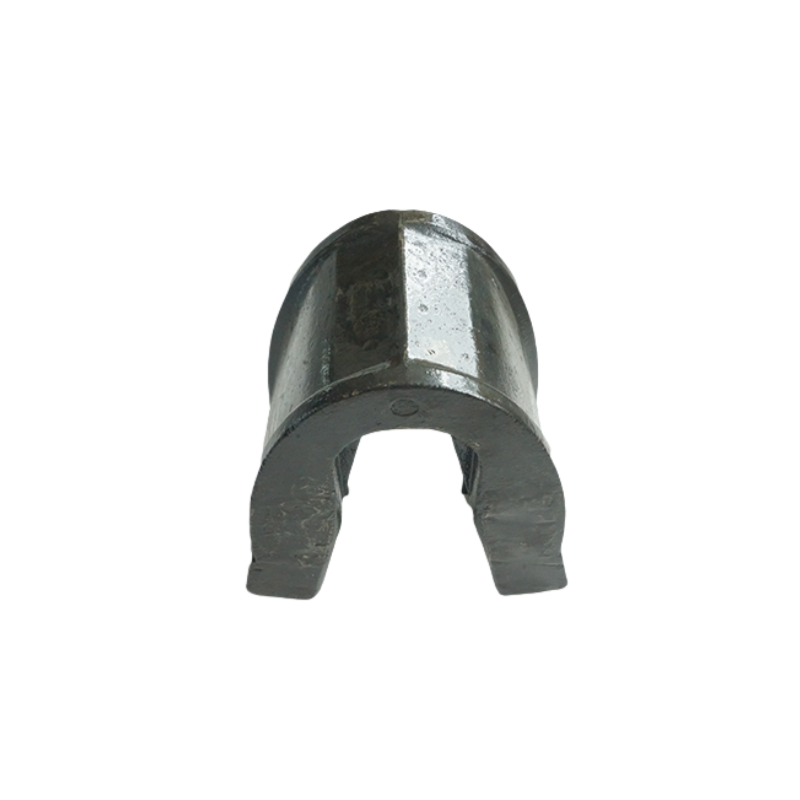

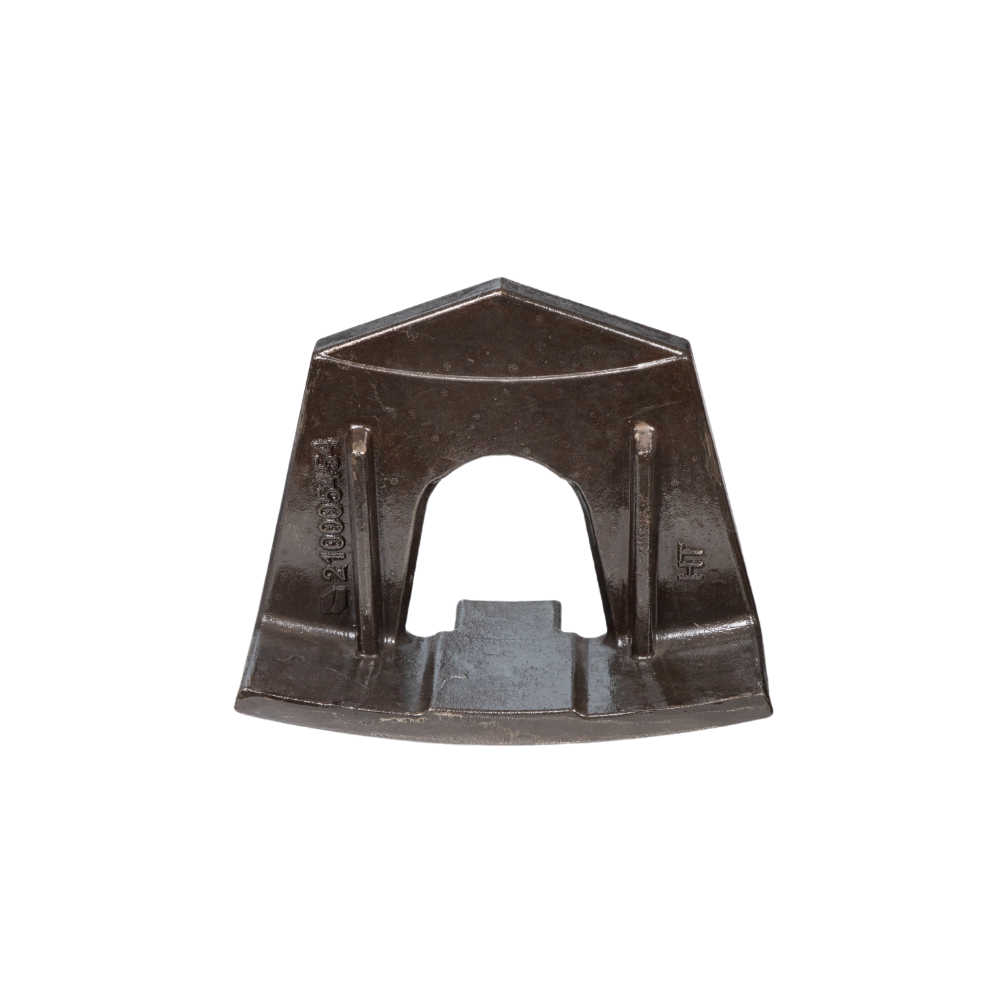

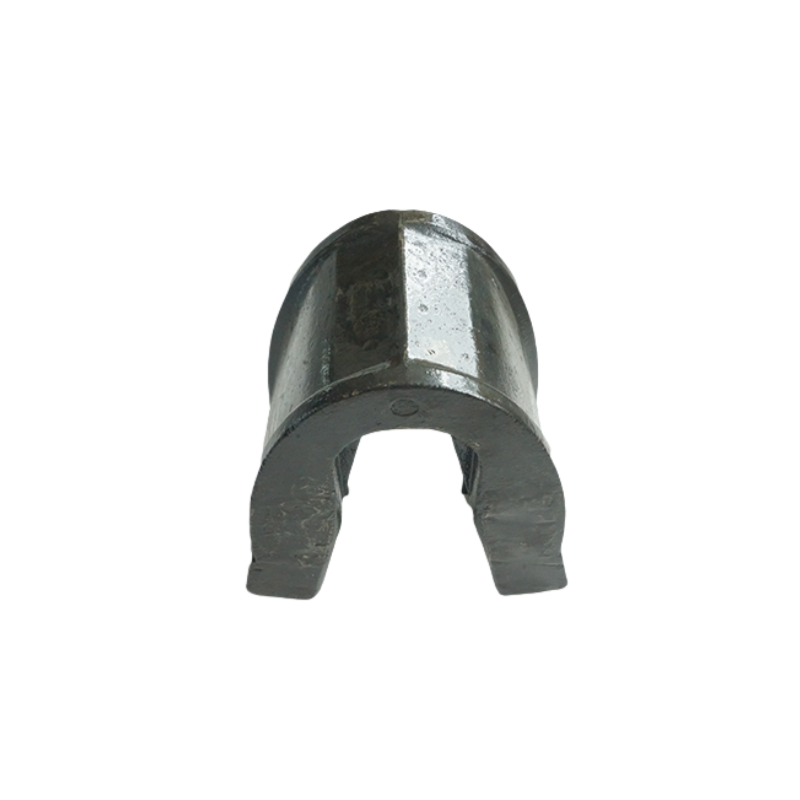

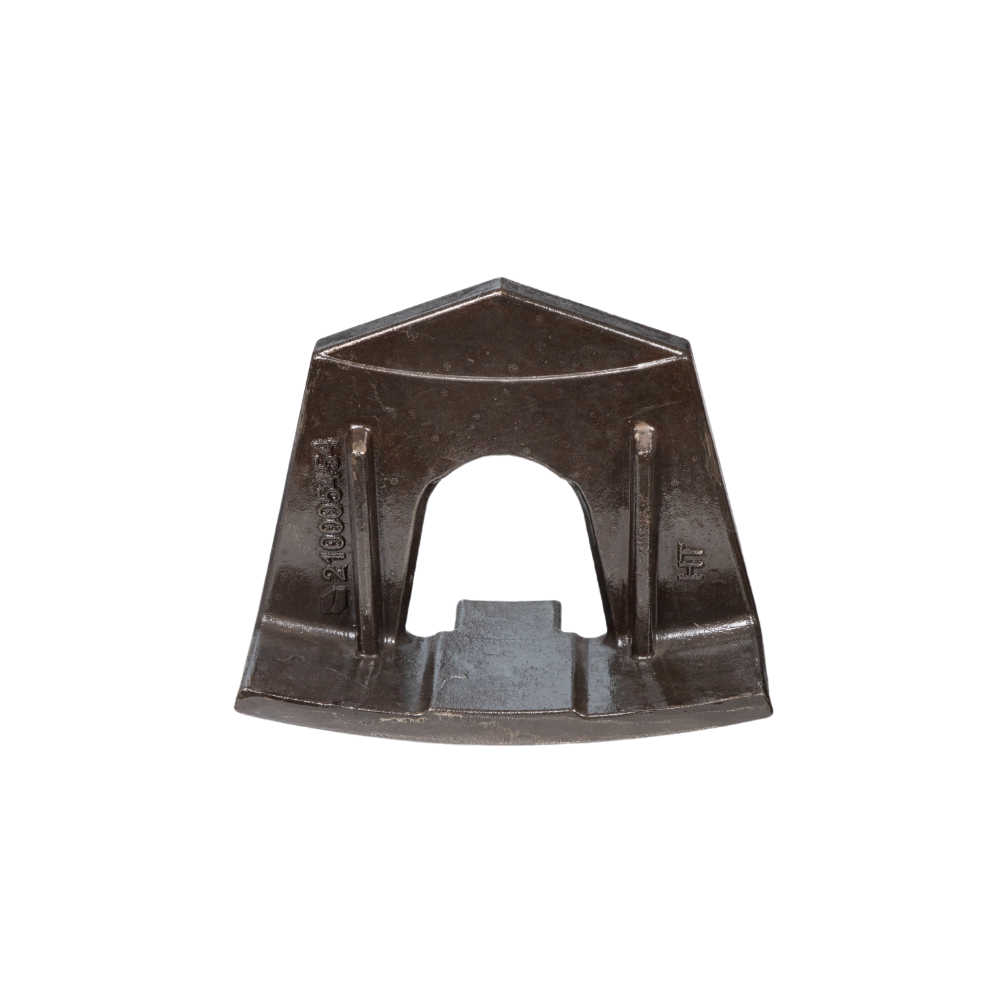

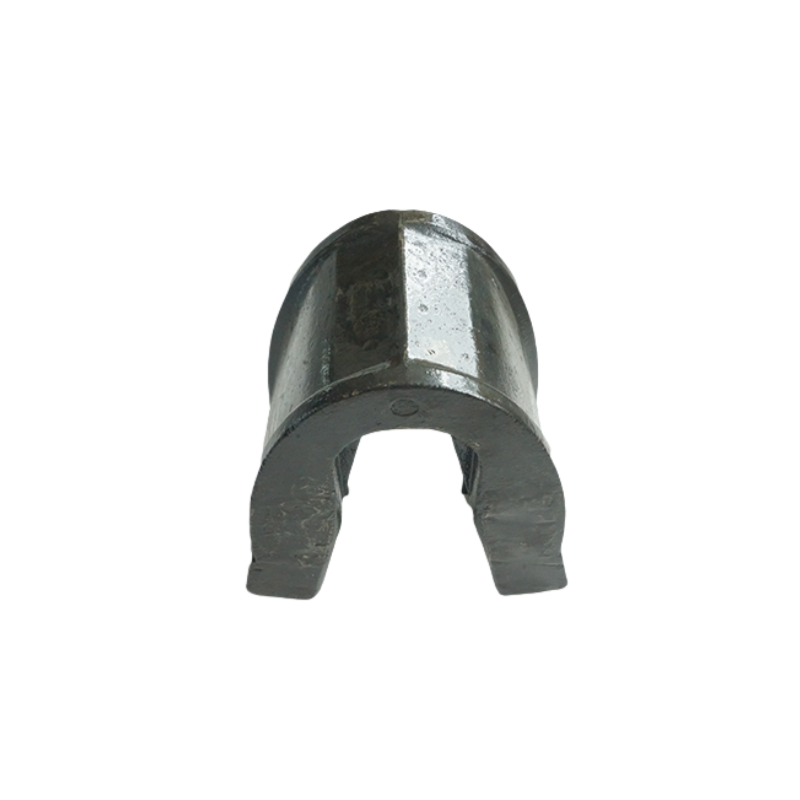

Sand Making Machine Hammer

-

Full Series Lining Plate

-

Long Service Life Crusher Jaw Plate

-

High-Quality Wear-Resistant Cone Crusher Parts

-

High-Quality Cone crusher Bowl Liner

-

Hammer-Sand Making Machine

-

High-Quality Wear-Resistant Hammer Plate

-

Superior Wear-Resistant Blow bar For Impact Crusher

-

Stable Quality Impact Crusher Blow Bar

-

Premium Wear-Resistant Plates

-

High-quality wear-resistant plates

-

Wear Parts of Jaw Crusher

-

Coal Mill Grinding Ball

-

General Lining Plate For Concrete Mixing Plant

-

Wear-resistant Lining Plate

-

Impact Resistant Lining plate For Concrete Mixing Plant

-

High Hardness Lining Plate For Concrete Mixing Plant

-

Mixing Arm For Concrete Mixing Plant

-

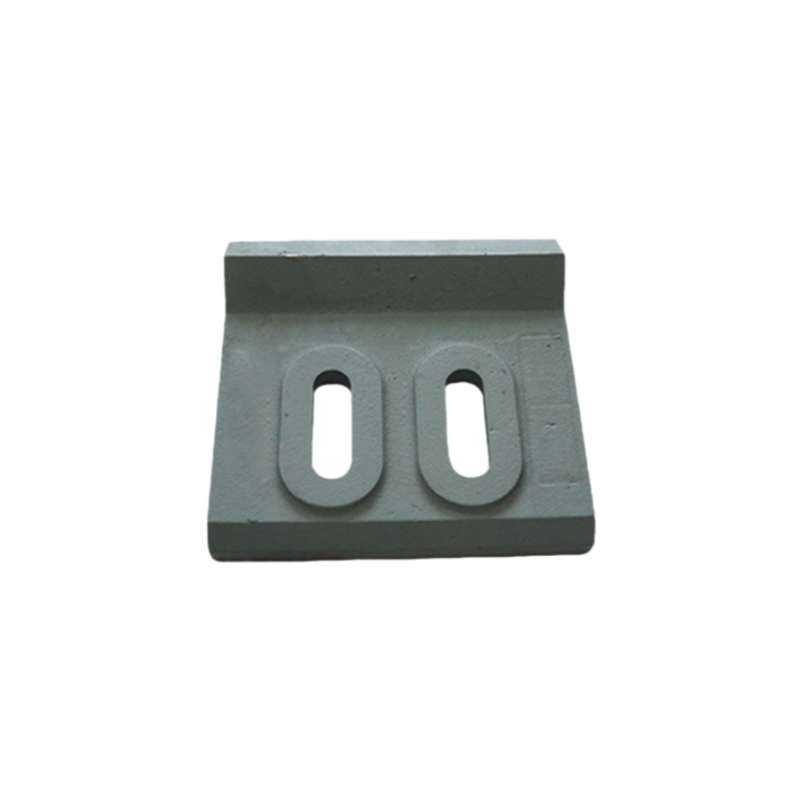

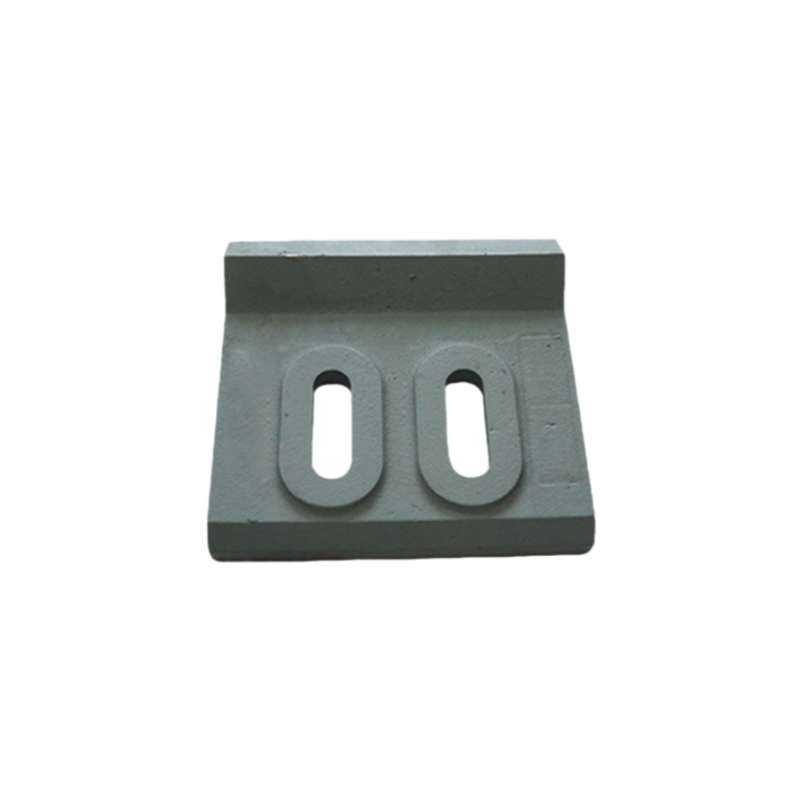

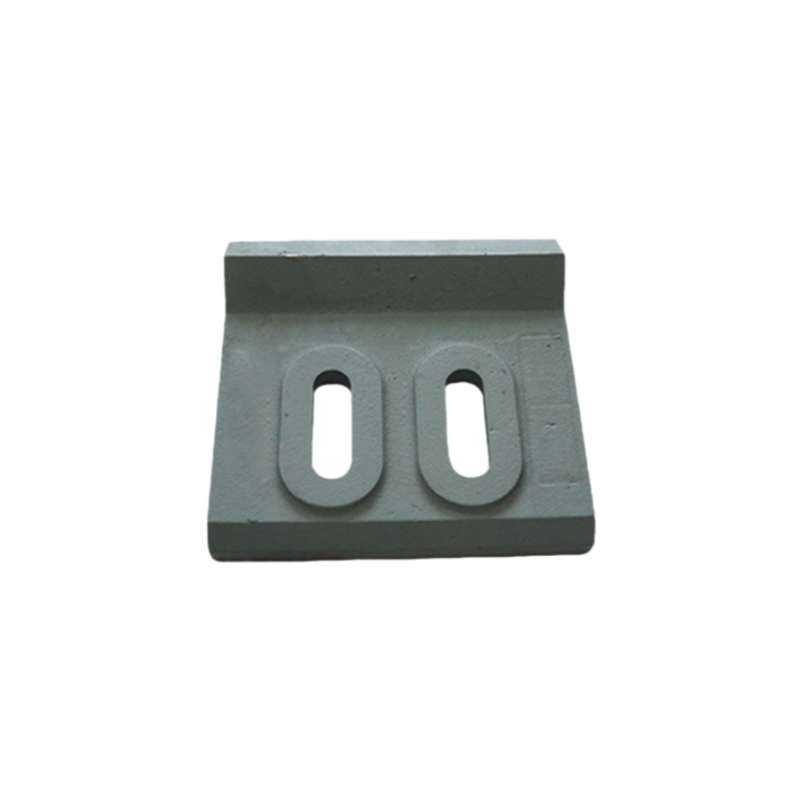

Arm Protection-Concrete Mixing Plant

-

Mixing Arm-Concrete Mixing Plant

-

Concrete Mixing Plant Wear-resistant Lining Plate

-

Concrete Mixing plant High-precision Scraper

-

Scraper-Concrete Mixing Plant

-

High Toughness Scraper For Concrete Mixing Plant

-

OEM Lining Plate For Concrete Mixing Plant

-

Concrete Mixing Plant Lining Plate

-

Concrete Mixing Plant High Wear-resistant Lining Plate

-

Concrete Mixing Plant Iron Casting Scraper

-

Concrete Mixing Plant Heat-resisting Lining Plate

-

Customizable Mixing Arm For Concrete Mixing Plant

-

Concrete Mixing Plant Wear Resistant Seal

-

Concrete Pump Truck Bend Pipe

-

Concrete Pump Truck Straight Pipe

-

Discharge Door ARC Liner

-

Lining Plate-Concrete Machinery

-

High Temperature Tolerance Lining Plate

-

Economical & Corrosion Resistance Blade

-

Concrete Mixing Plant Scraper Wear Parts

-

Strong Wear-resistant Seal

-

Diverse Choices Lining Plate

-

Concrete Mixing Plant Wear Resistant Scraper

-

Diverse Choices Lining Plate

-

Concrete Scraper High Efficiency

-

High Strength Lining Plate

-

Corrosion Resistance Scraper

-

Lining Plate For Asphalt Mixing Plant

-

Asphalt Paver Wear-resistant Spiral Blade

-

Lining Plate-Asphalt Mixing Plant

-

Asphalt Side Lining parts

-

Asphalt Machinery Series

-

Mixing Arm-Asphalt Mixing Plant

-

Spiral Blade For Asphalt Mixing Plant

-

Sealing element-Asphalt Mixing Plant

-

Scraper-Asphalt Mixing Blade

-

Strong Wear Resistance Lining Plate

-

Good Toughness Lining Plate

-

Spiral Blade-Asphalt Mixing Plant

-

High Temperature Resistance Plate

-

Good Strength Lining Plate

-

Asphalt Side Lining

-

Blow Bar For Smelting Equipment

-

High Quality Wear-Resistant Crusher Jaw Plate

-

High Quality Impact Crusher Blow Bar

-

Premium Impact Crusher Blow Bar

-

Cone crusher Bowl Liner

-

Powerful Cone Crusher Bowl Liner

-

Sand Making Machine Hammer

-

Full Series Lining Plate

-

Long Service Life Crusher Jaw Plate

-

High-Quality Wear-Resistant Cone Crusher Parts

-

High-Quality Cone crusher Bowl Liner

-

Hammer-Sand Making Machine

-

High-Quality Wear-Resistant Hammer Plate

-

Superior Wear-Resistant Blow bar For Impact Crusher

-

Stable Quality Impact Crusher Blow Bar

-

Premium Wear-Resistant Plates

-

High-quality wear-resistant plates

-

Wear Parts of Jaw Crusher

-

Coal Mill Grinding Ball

-

General Lining Plate For Concrete Mixing Plant

-

Wear-resistant Lining Plate

-

Impact Resistant Lining plate For Concrete Mixing Plant

-

High Hardness Lining Plate For Concrete Mixing Plant

-

Mixing Arm For Concrete Mixing Plant

-

Arm Protection-Concrete Mixing Plant

-

Mixing Arm-Concrete Mixing Plant

-

Concrete Mixing Plant Wear-resistant Lining Plate

-

Concrete Mixing plant High-precision Scraper

-

Scraper-Concrete Mixing Plant

-

High Toughness Scraper For Concrete Mixing Plant

-

OEM Lining Plate For Concrete Mixing Plant

-

Concrete Mixing Plant Lining Plate

-

Concrete Mixing Plant High Wear-resistant Lining Plate

-

Concrete Mixing Plant Iron Casting Scraper

-

Concrete Mixing Plant Heat-resisting Lining Plate

-

Customizable Mixing Arm For Concrete Mixing Plant

-

Concrete Mixing Plant Wear Resistant Seal

-

Concrete Pump Truck Bend Pipe

-

Concrete Pump Truck Straight Pipe

-

Discharge Door ARC Liner

-

Lining Plate-Concrete Machinery

-

High Temperature Tolerance Lining Plate

-

Economical & Corrosion Resistance Blade

-

Concrete Mixing Plant Scraper Wear Parts

-

Strong Wear-resistant Seal

-

Diverse Choices Lining Plate

-

Concrete Mixing Plant Wear Resistant Scraper

-

Diverse Choices Lining Plate

-

Concrete Scraper High Efficiency

-

High Strength Lining Plate

-

Corrosion Resistance Scraper

-

Lining Plate For Asphalt Mixing Plant

-

Asphalt Paver Wear-resistant Spiral Blade

-

Lining Plate-Asphalt Mixing Plant

-

Asphalt Side Lining parts

-

Asphalt Machinery Series

-

Mixing Arm-Asphalt Mixing Plant

-

Spiral Blade For Asphalt Mixing Plant

-

Sealing element-Asphalt Mixing Plant

-

Scraper-Asphalt Mixing Blade

-

Strong Wear Resistance Lining Plate

-

Good Toughness Lining Plate

-

Spiral Blade-Asphalt Mixing Plant

-

High Temperature Resistance Plate

-

Good Strength Lining Plate

-

Asphalt Side Lining

-

Blow Bar For Smelting Equipment

-

High Quality Wear-Resistant Crusher Jaw Plate

-

High Quality Impact Crusher Blow Bar

-

Premium Impact Crusher Blow Bar

-

Cone crusher Bowl Liner

-

Powerful Cone Crusher Bowl Liner

-

Sand Making Machine Hammer

-

Full Series Lining Plate

-

Long Service Life Crusher Jaw Plate

-

High-Quality Wear-Resistant Cone Crusher Parts

-

High-Quality Cone crusher Bowl Liner

-

Hammer-Sand Making Machine

-

High-Quality Wear-Resistant Hammer Plate

-

Superior Wear-Resistant Blow bar For Impact Crusher

-

Stable Quality Impact Crusher Blow Bar

-

Premium Wear-Resistant Plates

-

High-quality wear-resistant plates

-

Wear Parts of Jaw Crusher

-

Coal Mill Grinding Ball

-

General Lining Plate For Concrete Mixing Plant

-

Wear-resistant Lining Plate

-

Impact Resistant Lining plate For Concrete Mixing Plant

-

High Hardness Lining Plate For Concrete Mixing Plant

-

Mixing Arm For Concrete Mixing Plant

-

Arm Protection-Concrete Mixing Plant

-

Mixing Arm-Concrete Mixing Plant

-

Concrete Mixing Plant Wear-resistant Lining Plate

-

Concrete Mixing plant High-precision Scraper

-

Scraper-Concrete Mixing Plant

-

High Toughness Scraper For Concrete Mixing Plant

-

OEM Lining Plate For Concrete Mixing Plant

-

Concrete Mixing Plant Lining Plate

-

Concrete Mixing Plant High Wear-resistant Lining Plate

-

Concrete Mixing Plant Iron Casting Scraper

-

Concrete Mixing Plant Heat-resisting Lining Plate

-

Customizable Mixing Arm For Concrete Mixing Plant

-

Concrete Mixing Plant Wear Resistant Seal

-

Concrete Pump Truck Bend Pipe

-

Concrete Pump Truck Straight Pipe

-

Discharge Door ARC Liner

-

Lining Plate-Concrete Machinery

-

High Temperature Tolerance Lining Plate

-

Economical & Corrosion Resistance Blade

-

Concrete Mixing Plant Scraper Wear Parts

-

Strong Wear-resistant Seal

-

Diverse Choices Lining Plate

-

Concrete Mixing Plant Wear Resistant Scraper

-

Diverse Choices Lining Plate

-

Concrete Scraper High Efficiency

-

High Strength Lining Plate

-

Corrosion Resistance Scraper

-

Lining Plate For Asphalt Mixing Plant

-

Asphalt Paver Wear-resistant Spiral Blade

-

Lining Plate-Asphalt Mixing Plant

-

Asphalt Side Lining parts

-

Asphalt Machinery Series

-

Mixing Arm-Asphalt Mixing Plant

-

Spiral Blade For Asphalt Mixing Plant

-

Sealing element-Asphalt Mixing Plant

-

Scraper-Asphalt Mixing Blade

-

Strong Wear Resistance Lining Plate

-

Good Toughness Lining Plate

-

Spiral Blade-Asphalt Mixing Plant

-

High Temperature Resistance Plate

-

Good Strength Lining Plate

-

Asphalt Side Lining

-

Blow Bar For Smelting Equipment

-

High Quality Wear-Resistant Crusher Jaw Plate

-

High Quality Impact Crusher Blow Bar

-

Premium Impact Crusher Blow Bar

-

Cone crusher Bowl Liner

-

Powerful Cone Crusher Bowl Liner

-

Sand Making Machine Hammer

-

Full Series Lining Plate

-

Long Service Life Crusher Jaw Plate

-

High-Quality Wear-Resistant Cone Crusher Parts

-

High-Quality Cone crusher Bowl Liner

-

Hammer-Sand Making Machine

-

High-Quality Wear-Resistant Hammer Plate

-

Superior Wear-Resistant Blow bar For Impact Crusher

-

Stable Quality Impact Crusher Blow Bar

-

Premium Wear-Resistant Plates

-

High-quality wear-resistant plates

-

Wear Parts of Jaw Crusher

-

Coal Mill Grinding Ball

-

General Lining Plate For Concrete Mixing Plant

EQIUPMENTFORWHICHWESUPPLYWEARPARTS

-

Concrete Equipment

-

Pavement Mechanical Equipment

-

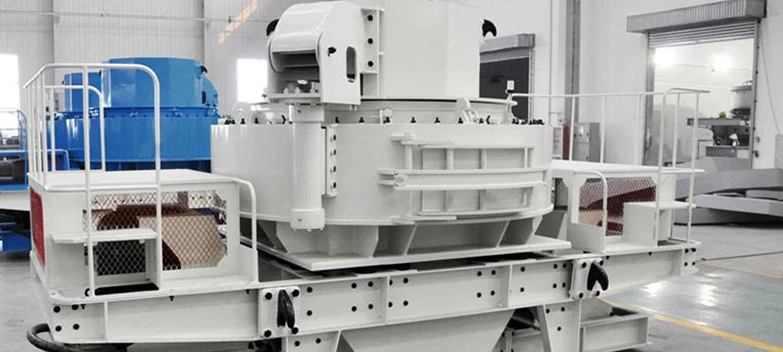

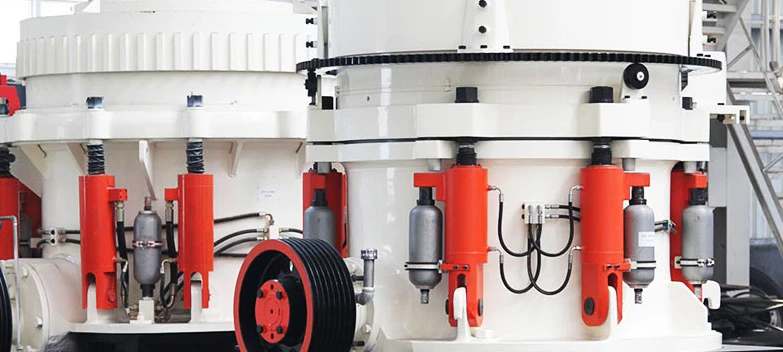

Mining Equipment

-

Metallurgical Equipment.

CUSTOMER REVIEWS

INTRODUCTION

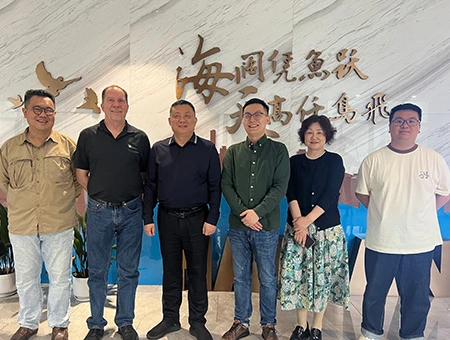

In October 2023, Astec, an American customer, came to our company to discuss the wear-resistant casting project, recognized our composite ceramic technology, and confirmed the new product development order.

INTRODUCTION

In May 2024, the purchasing manager and engineer of Putzmeister, a German customer, came to our company to discuss the hinge bending problem, highly commented on our production technology and equipment, and confirmed the intention order.

INTRODUCTION

In April 2024, at the Intermat exhibition in France, French customers came to consult about the products.

INTRODUCTION

In April 2024, at the Intermat exhibition in France, we discussed the problem on site with the Turkish customer elkon, and the product was highly evaluated by the customer.

INTRODUCTION

In June 2024, Sun Heng, the general manager of the company, led a team to participate in the Russian Construction Machinery Exhibition, and the product quality was recognized by Russian customers.

English

English بالعربية

بالعربية Deutsch

Deutsch Français

Français Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 қазақ

қазақ 한국어

한국어 Bahasa Malay

Bahasa Malay Монгол

Монгол Nederlands

Nederlands Język polski

Język polski Português

Português Русский язык

Русский язык Español

Español ภาษาไทย

ภาษาไทย Türkçe

Türkçe

Tel:

Tel:  Fax: 0555-6971198

Fax: 0555-6971198 Website:

Website:  Email:

Email:  Postal code: 243141

Postal code: 243141 Address: Xinshi Industrial Park, Bowang District, Ma’anshan City, Anhui Province, China

Address: Xinshi Industrial Park, Bowang District, Ma’anshan City, Anhui Province, China

Tik Tok

Tik Tok